Plate cutting machine for copper-clad plate production

A technology of copper clad laminates and cutting machines, which is applied in the direction of shearing devices, metal processing machinery parts, manufacturing tools, etc., to achieve the effect of improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

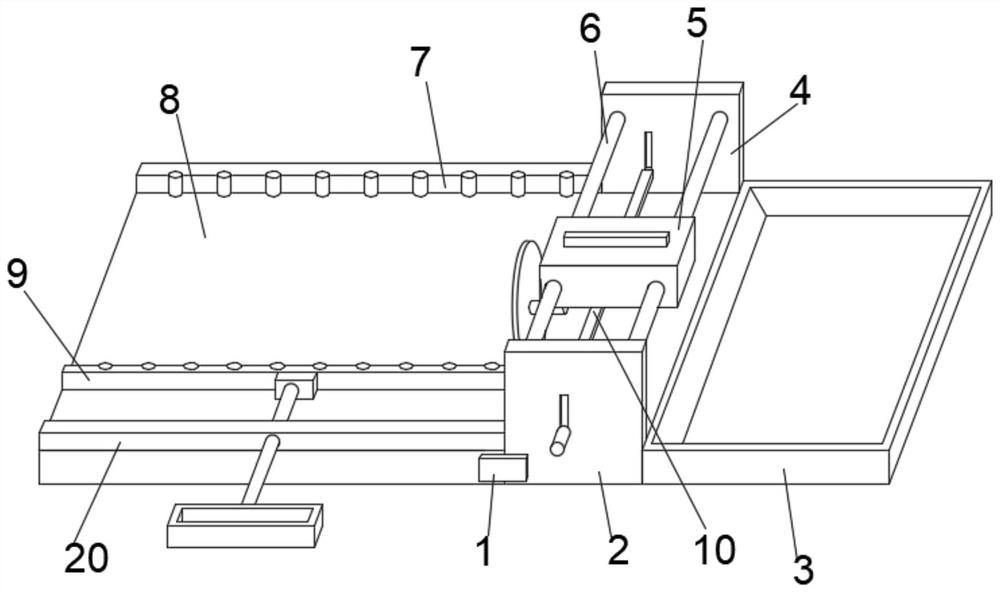

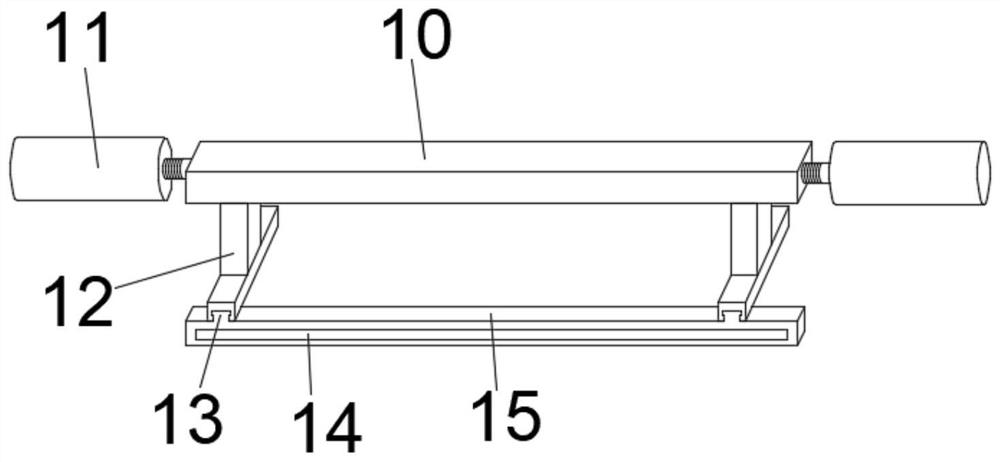

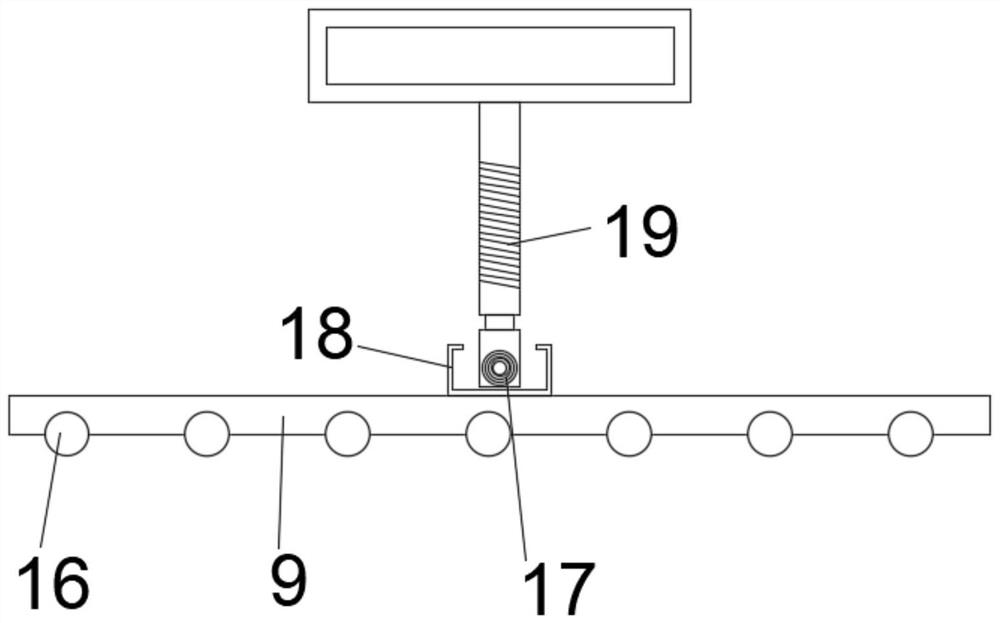

[0032] like Figure 1-5 As shown, a cutting machine for copper clad laminate production includes a fixed base plate 8 and a cutting plate 28, the upper part of the fixed base plate 8 is movably installed with a sliding seat 5, the cutting plate 28 is movably installed on one side of the sliding seat 5, and the fixed base plate 8 A first support plate 2 is fixedly installed on the outer surface of one side of the fixed base plate 8, a second support plate 4 is fixedly installed on the outer surface of the other side of the fixed base plate 8, and a lifting bar is movably installed between the second support plate 4 and the first support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com