Composite laser welding method

A laser welding and laser technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., to achieve high absorption rate, improve weld strength, and improve the effect of laser process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, according to the description in this document, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments.

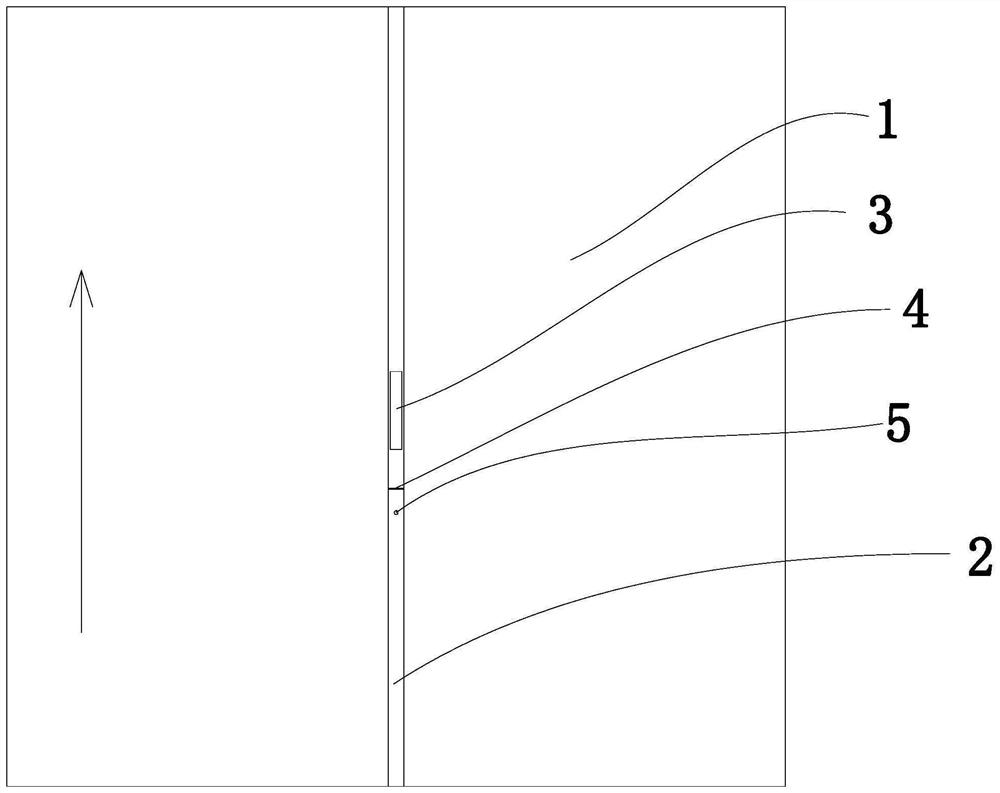

[0026] Examples of the present invention are as follows, refer to figure 1 , a composite laser welding method, comprising the following steps:

[0027] (1) Place the workpiece 1 to be welded on the welding table;

[0028] (2) Laser preheating: The preheating laser beam 3 (flat-top laser beam) runs to the position of the welding seam 2, and the laser is turned on to start emitting light; the preheating laser beam 3 moves along the welding seam 2 at the welding seam 2 position to preheat workpiece to be welded;

[0029] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com