Elastic porous polishing white pad for display screen edge polishing and production process of elastic porous polishing white pad

A display screen and white pad technology, applied in the white pad field, can solve the problems that the polishing pad cannot be practically used for grinding operations, affects the overall elasticity and softness of the white pad, and the polishing pad cannot be polished, so as to save materials and facilitate edging operations , Optimize the effect of elasticity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

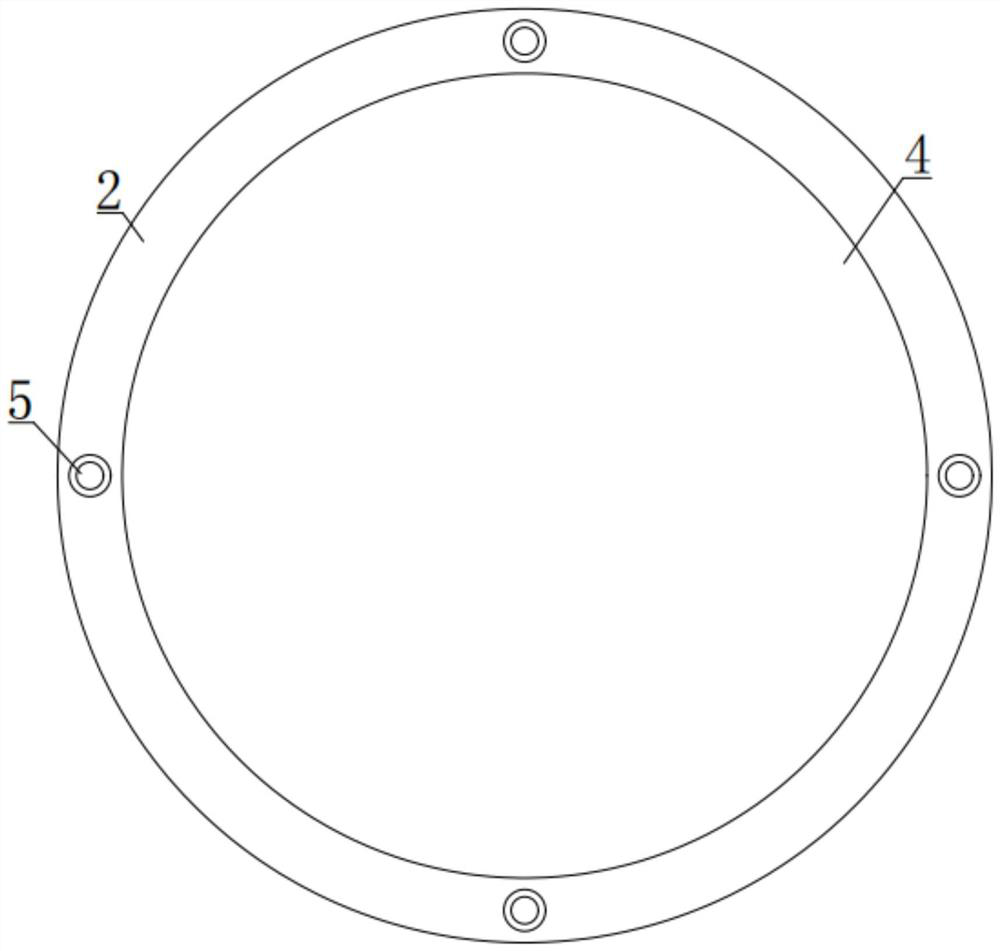

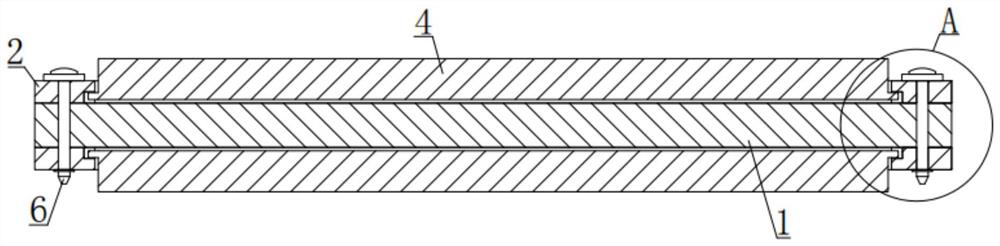

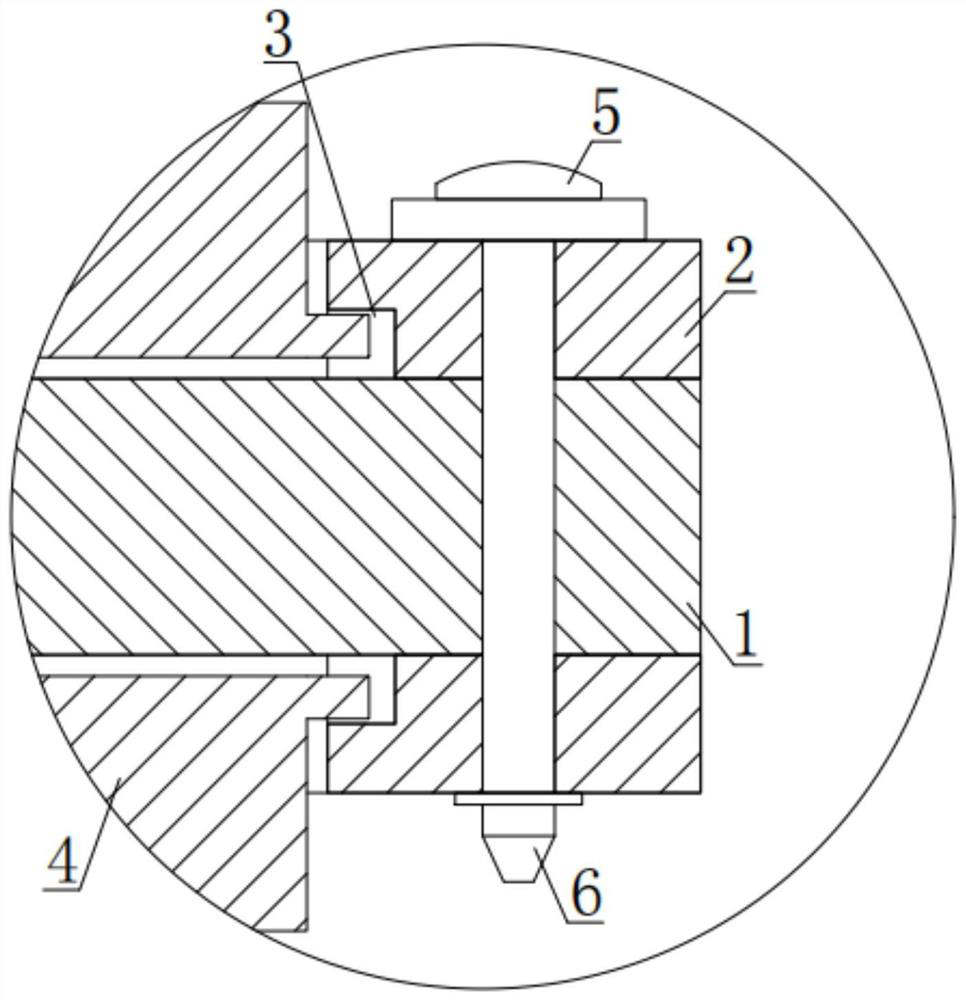

[0053] see Figure 1-Figure 3 , an elastic porous polishing white pad for edging a display screen, comprising a core elastic layer 1, a white pad connecting sleeve 2, an embedded groove 3, a frosted white pad 4, a nylon outer ferrule 5 and a nylon ferrule seat 6, the core elastic The upper and lower sides of the layer 1 are respectively provided with a white pad connecting sleeve 2, and the interior of the white pad connecting sleeve 2 is provided with an embedded groove 3, and a frosted white pad 4 is installed in the embedded groove 3, and the frosted white pad 4 is the core polishing part. Nylon outer ferrule 5 is installed on the side of elastic layer 1 and white pad connecting sleeve 2, nylon outer ferrule 5 is installed on the bottom of nylon ferrule seat 6, nylon outer ferrule 5 and nylon ferrule seat 6 are combined, and the core elastic layer 1 It is connected with the white pad connecting sleeve 2 as a whole.

[0054] see Figure 4 , the frosted white pad 4 includes...

Embodiment 2

[0083] The only difference between this embodiment and the first embodiment is that the material ratio of the styrene thermoplastic elastomer and the polyester thermoplastic elastomer in the raw materials used for the core elastic layer 1 and the white pad connecting sleeve 2 is different. The weight fraction ratio of the raw materials used for layer 1 and white pad connecting cover 2 is as follows:

[0084] 80 parts of styrene thermoplastic elastomer;

[0085] 40 parts of polyester thermoplastic elastomer;

[0086] 2 parts of antioxidant;

[0087] 6 parts of wear-resistant additives;

[0088] 22 parts of nanofillers;

[0089] The weight ratio between the styrene-based thermoplastic elastomer and the polyester-based thermoplastic elastomer is changed to 2:1, that is, the styrene-based thermoplastic elastomer is used as the preparation main body, and the polyester-based thermoplastic elastomer is used as the filler.

Embodiment 3

[0091] The difference between this embodiment and the first embodiment is only that the proportions of the components by weight of the raw materials used for the high elasticity layer 41 and the polishing surface layer 43 are different. The proportions of copies are as follows:

[0092] 30 parts of styrene-butadiene rubber;

[0093] 15 parts of polyurethane elastic fiber;

[0094] 2 parts of triethanolamine;

[0095] 2 parts of triethylenediamine;

[0096] 2 parts of magnesium oxide;

[0097] 3 auxiliary preparations;

[0098] The proportion of polyurethane elastic fibers in styrene-butadiene rubber and polyurethane elastic fibers is increased, thereby reducing the overall elasticity of the high elastic layer 41 and the polishing surface layer 43 prepared as a whole, and improving their overall softness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com