Low-carbon operation salt-containing wastewater treatment system and method applying solar energy and loop heat pipe

A loop heat pipe and saline wastewater technology, applied in the direction of heating water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of increasing carbon emissions of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

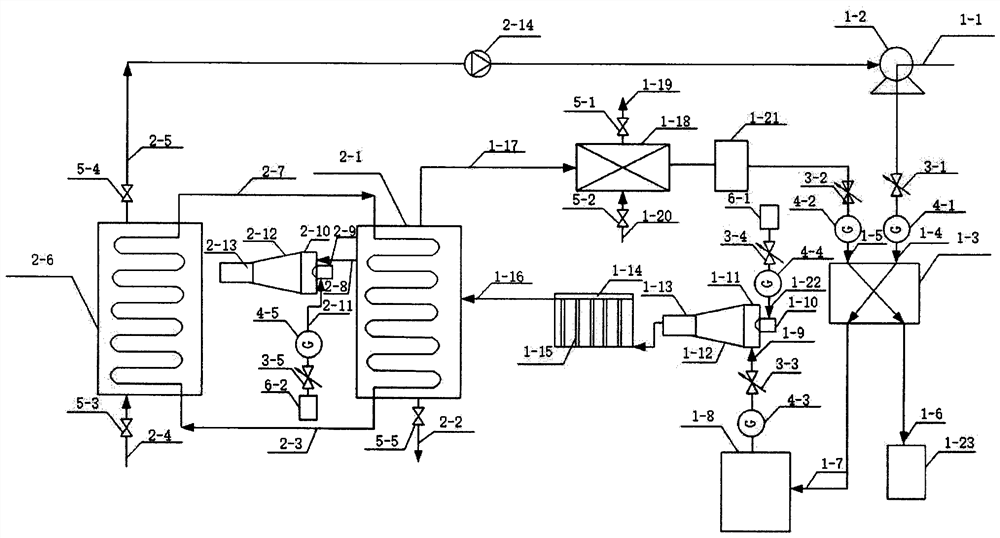

[0030] like figure 1 As shown, a low-carbon operation salt-containing wastewater treatment system using solar energy and loop heat pipes mainly includes material inlet 1-1, material circulation pump 1-2, plate preheating heat exchanger 1-3, normal temperature material inlet 1- 4. High temperature condensate water inlet 1-5, low temperature condensate water outlet 1-6, preheating material outlet 1-7, material storage tank 1-8, preheating material inlet 1-9, first ejector nozzle 1- 10. Mixed liquid inlet 1-11, first ejector shrinking tube 1-12, first ejector mixing tube 1-13, solar heat absorbing film 1-14, solar heating coil 1-15, high temperature material inlet 1-16, secondary steam outlet 1-17, condensing heat exchanger 1-18, groundwater outlet 1-19, groundwater inlet 1-20, high temperature condensate tank 1-21, first high pressure gas inlet 1-22, low temperature condensation Water tank 1-23, heat pipe condensation section 2-1, material concentrate outlet 2-2, working fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com