Solid-liquid separation structure for electrolytic tank

A technology of solid-liquid separation and electrolysis box, applied in electrolysis components, electrolysis process, instruments, etc., can solve the problems of slow solid-liquid separation, affecting production efficiency, hindered circulation of electrolytic solution, etc., to promote solid-liquid separation and improve production efficiency. , the effect of facilitating the collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

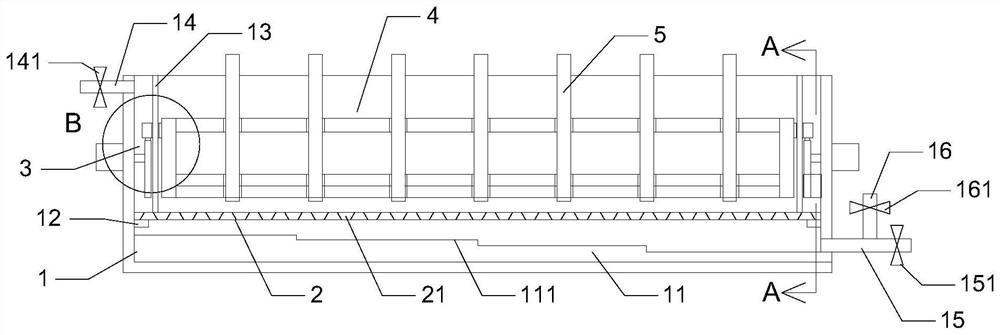

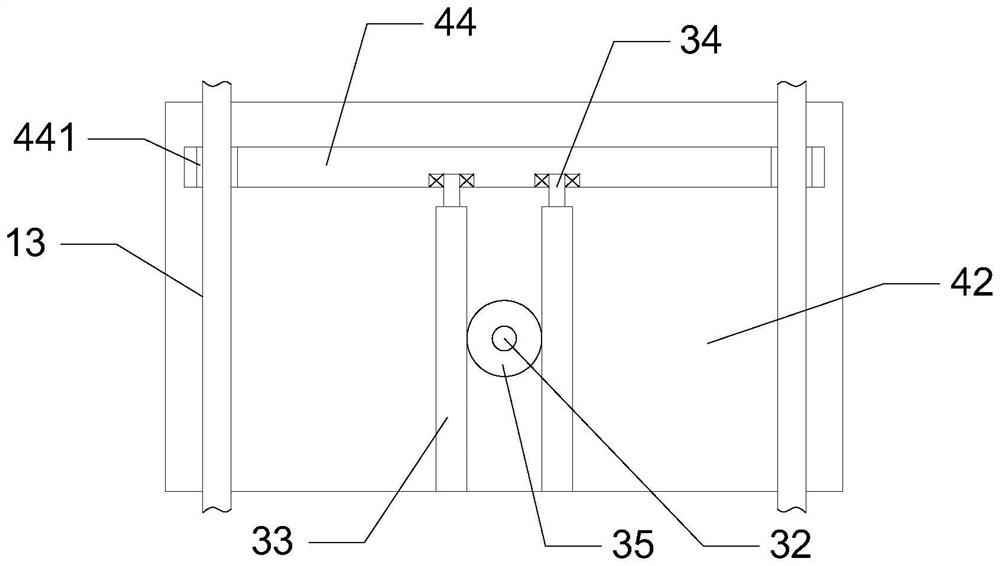

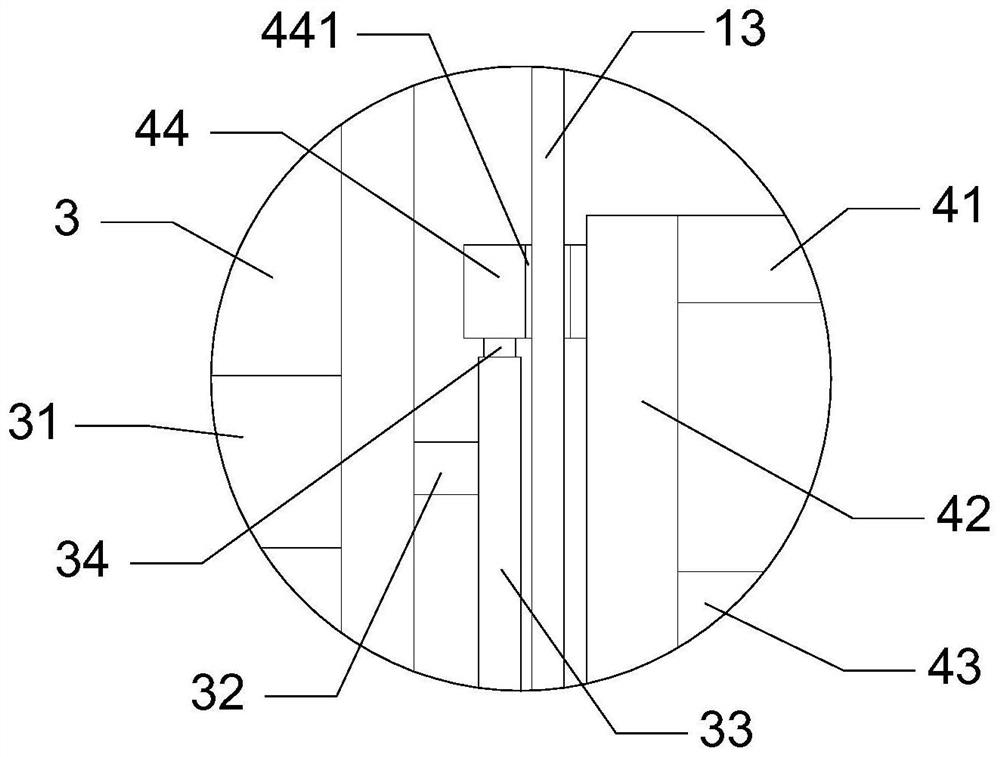

[0024] like Figures 1 to 6 As shown, a solid-liquid separation structure for an electrolytic tank includes an electrolytic tank 1 , a partition plate 2 , a lifting mechanism 3 , a lifting bracket 4 and an electrolytic box 5 .

[0025] Wherein, a guide plate 11 is embedded at the bottom of the above-mentioned electrolytic cell 1, and a guide step 111 is arranged on the upper surface of the guide plate 11. In the process of discharging the electrolytic solution, it can play a good guiding role, and promote the rapid outflow of the electrolytic solution from left to right. And the electrolytic solution between the bottom of the electrolytic cell 1, so that the electrolytic solution is not affected by the electrolytic box 5, and can flow quickly, the lifting bracket 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com