Annular multi-supporting-point adjustable profile steel support changing system and construction method

A support point and adjustable technology, applied in construction, building maintenance, building construction, etc., can solve the problems of increasing construction costs, demolition and redo, not satisfying environmental protection, etc., to achieve convenient and fast construction, and small scope of demolition and modification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

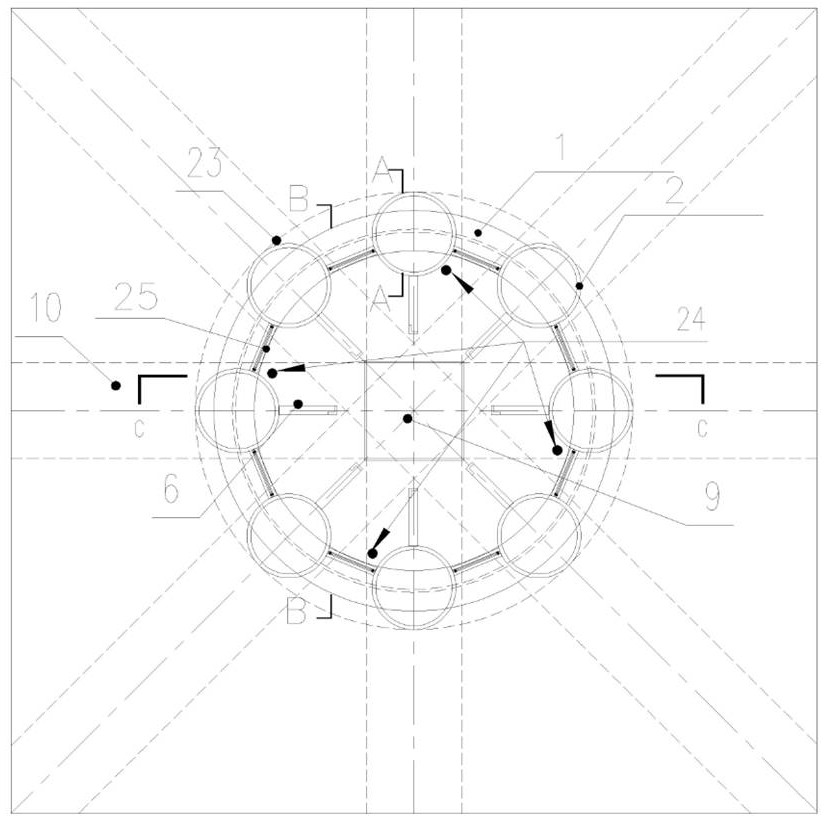

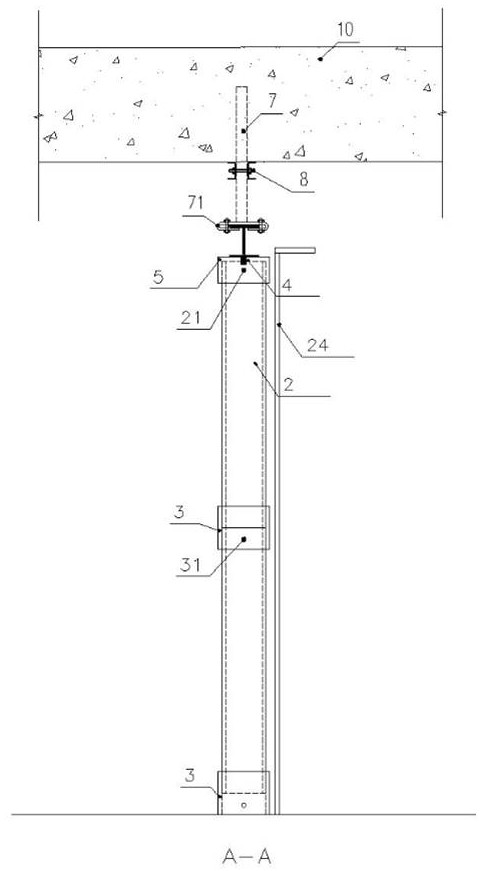

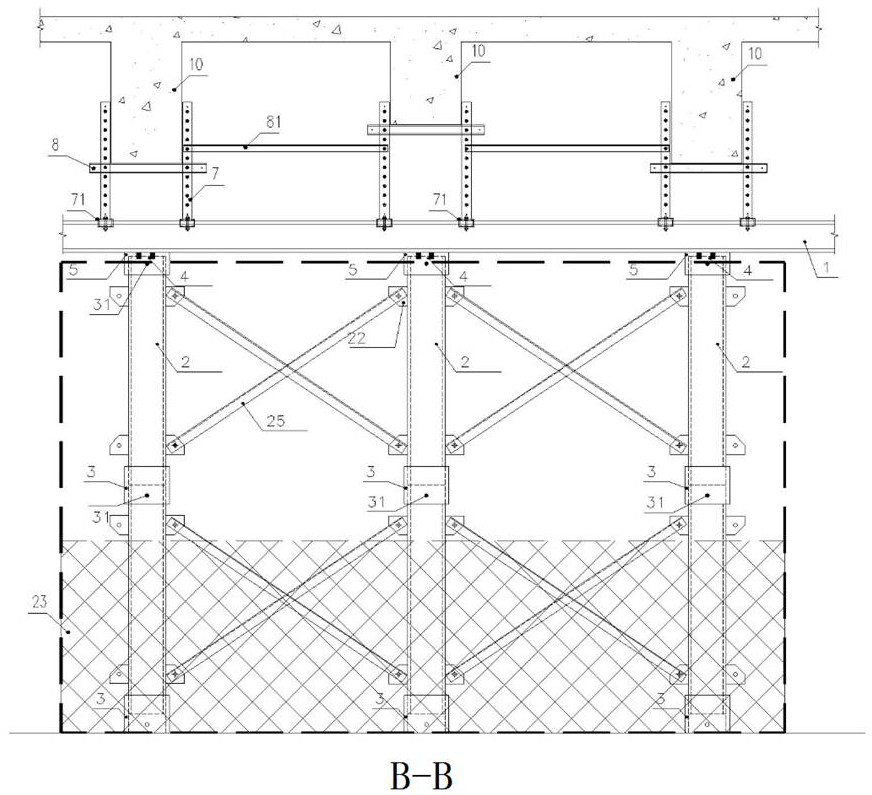

[0040] In this example, the demolition and reinforcement of large and old complex structural columns are taken as a construction case. figure 1 The middle structural beam 10 and the structural column 9 constitute the basic structural stress system. Since the structural column 9 is severely corroded due to the change of the upper load and the structural column 9 itself needs to be dismantled and rebuilt, the column section is enlarged and concrete is poured again. The floor structure above the support area of the structural column 9 is the area for people to flow, and the equipment in the adjacent rooms must be in normal operation. out. Due to the special needs of the building properties of the complex, the overall building renovation cannot affect the normal operation of the merchants in the building, and the electromechanical equipment room in the basement needs to operate normally, and the renovation project meets the requirements for environmental protection and safety. ...

Embodiment 2

[0048] In a preferred embodiment, the adjustable section steel bracing system with multiple support points in the ring also includes a combined operation platform 6, and the combined operation platform 6 is fixed on the inner side of the uppermost section of the section steel column 2 through the second connecting plate 61, and the combined operation platform 6 is combined. The operating platform 6 includes a vertical pole 62 and an oblique support 63 .

[0049] Further, in order to reduce the impact of dust during concrete construction, a dense mesh type dust screen 23 is hung on the outer side of the profiled steel column 2, and a spray water pipe 24 is welded on the inner side to achieve the purpose of dust reduction and protection. The combined operation platform 6 solves the difficulty of the worker's working face and the problem of rebuilding the operation frame, and the spray water pipe 24 can be changed to a maintenance water pipe under the construction environment agai...

Embodiment 3

[0051] The invention also provides a construction method for dismantling and modifying a frame column structure, comprising the following steps:

[0052] Step S1 , according to the actual construction situation, measure and calculate the height of the structural floor, the position and cross-sectional characteristics of the structural beam 10 , and the cross-sectional size of the structural column 9 to be demolished to select an appropriate force-bearing member.

[0053] Step S2, install the above-mentioned adjustable section steel bracing system with multiple support points at the position of the structural column 9, which specifically includes:

[0054] In step S21, multiple groups of profiled steel columns 2 are arranged at equal intervals in the circumferential direction around the structural column 9, and the profiled steel columns 2 are arranged directly below the structural beam 10. The section steel column 2 is fixedly connected through the sleeve 3 along the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com