Petrochemical engineering machine pump group operation monitoring and fault diagnosis system based on ad hoc network and management method

A fault diagnosis system and petrochemical technology, applied in the direction of using liquid/vacuum degree for liquid tightness measurement, pump, pump device, etc., can solve the problem of real-time monitoring of the mechanical tightness of the pump body of the pump group and the inability to receive prompts in time , It is impossible to send the pump and other problems to the operator in time, so as to ensure the normal and stable operation, reduce labor intensity, and achieve the effect of high intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

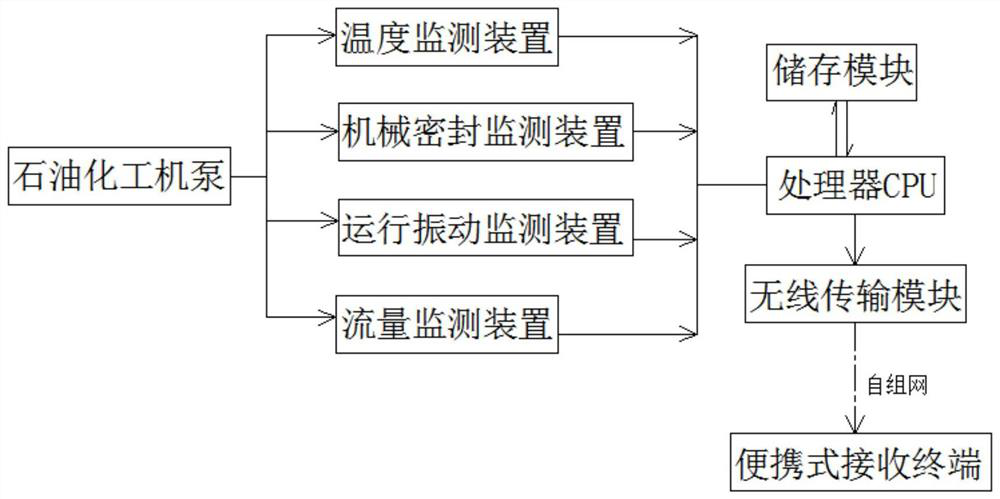

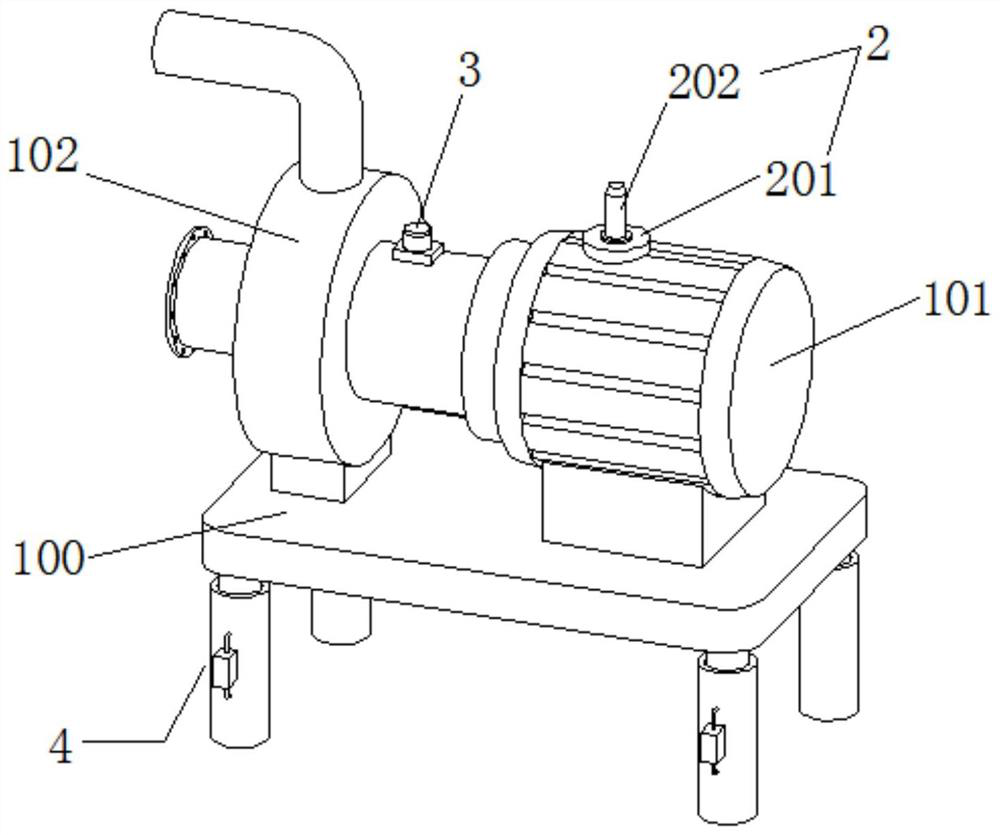

[0052] The present embodiment 1 discloses a petrochemical pump group operation monitoring and fault diagnosis system based on an ad hoc network, the main components of which include a control cabinet 10, a portable receiving terminal, and a pump composed of multiple petrochemical pumps 1 group. Each petrochemical engine pump 1 is provided with a temperature monitoring device 2, a pump body mechanical seal monitoring device 3, a running vibration monitoring device 4, and a flow rate monitoring device for a single petrochemical engine pump 1 and a total monitoring device for the pump group. Flow monitoring device 5 for flow.

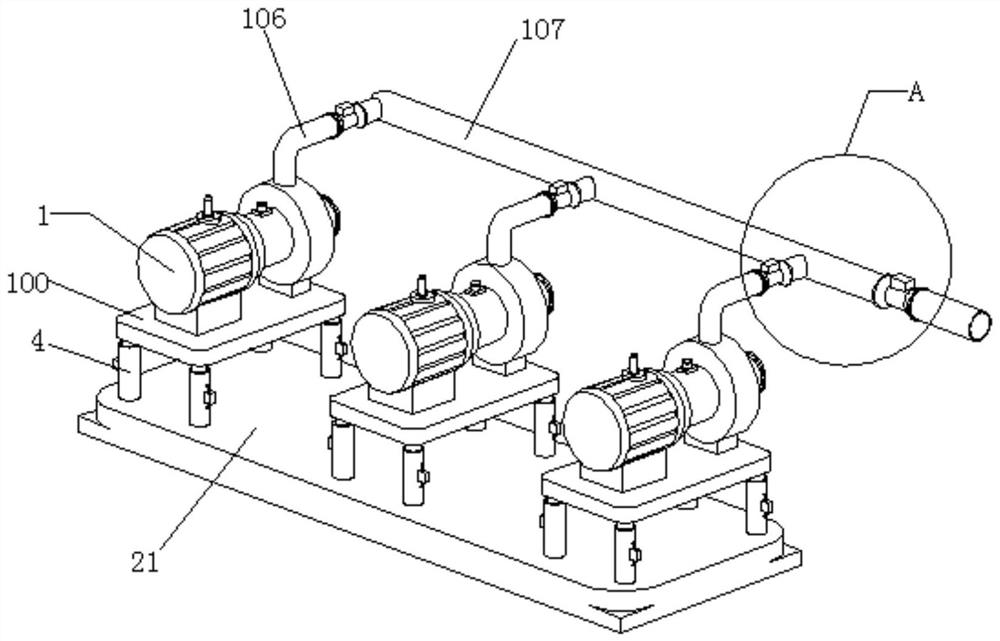

[0053] Reference attached figure 2 A plurality of petrochemical pumps 1 are neatly arranged in a row to form a pump group, a mounting base plate 21 is arranged below a row of petrochemical pumps 1 , and an organic pump seat 100 is arranged at the lower end of each petrochemical pump 1 .

[0054] Reference attached figure 2 , attached image 3 , attac...

Embodiment 2

[0060] Embodiment 2 discloses an improved self-organized network-based petrochemical engine pump group operation monitoring and fault diagnosis system based on Embodiment 1. The same points as those in Embodiment 1 will not be described again, and the differences are not described again. in:

[0061] In Embodiment 2, the outer surface of the pressure sensor 1082 disposed inside the nozzle 1081 is also coated with a corrosion-resistant layer, so as to protect the pressure sensor 1082 that has been in contact with oil for a long time and prolong its service life.

[0062] In addition, in Embodiment 2, sealant is also filled between the temperature probe and the jack on the temperature sensor 202, so that the pump motor 101 still has excellent water resistance after the temperature sensor 202 is installed.

[0063] The control cabinet 10 in Embodiment 2 is provided with a rectangular opening on its front side, and a cabinet door 16 is rotatably connected to the rectangular openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com