Four-side air inlet adjustable and controllable dry-wet combined cooling tower

A combined cooling and air intake technology, applied in water shower coolers, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as insufficient natural wind draft, and achieve good natural wind draft, good cooling effect, and heat dissipation high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

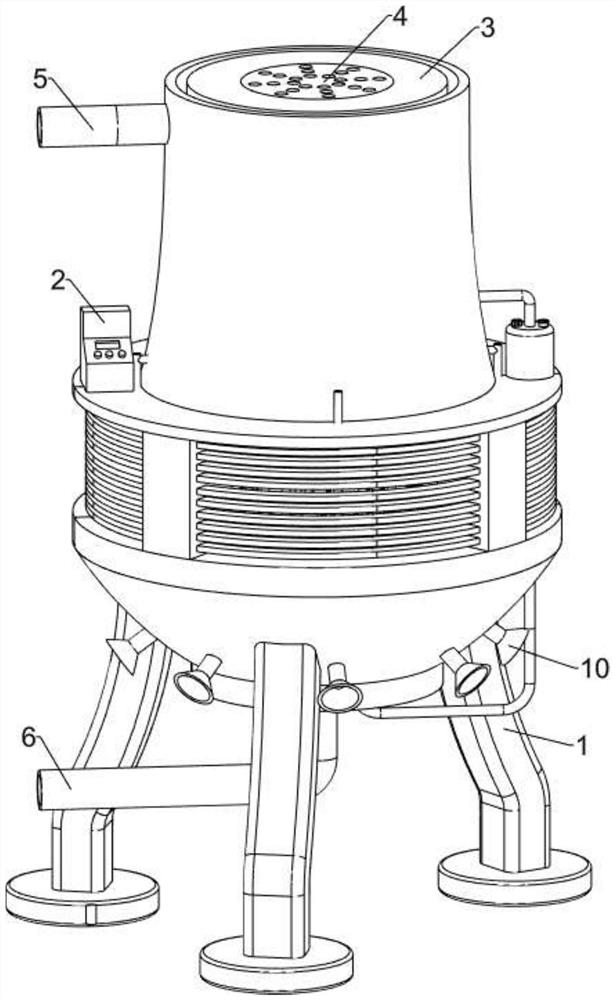

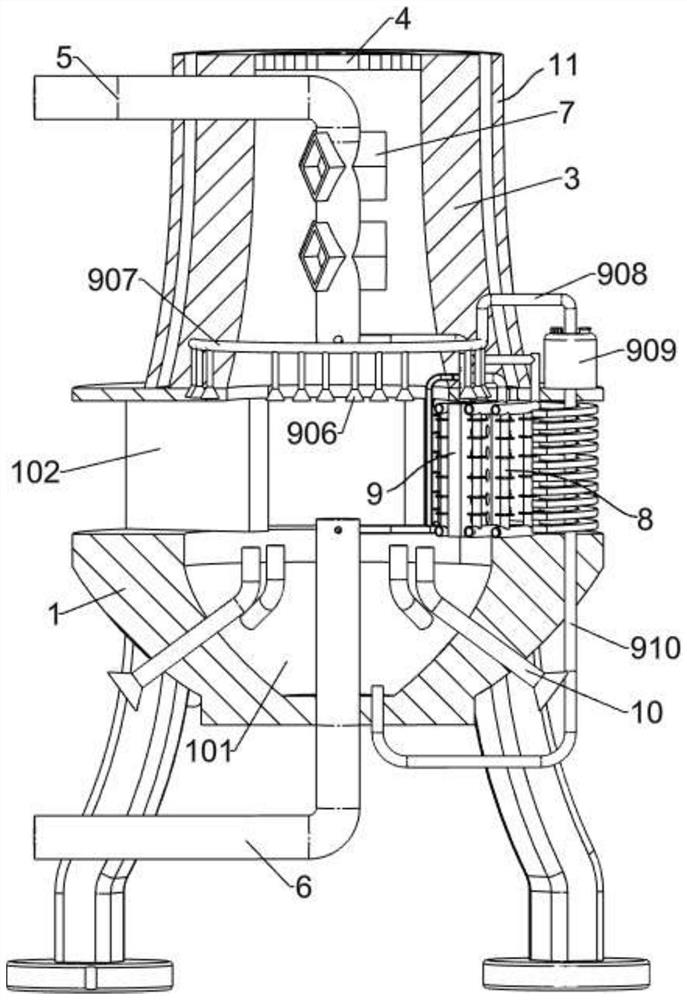

[0027] A dry and wet combined cooling tower with adjustable and controllable air intake from all sides, such as figure 1 and figure 2As shown, it includes a support frame 1, the upper part of the support frame 1 is provided with a water storage cavity 101, the water storage cavity 101 is filled with water, and the upper part of the support frame 1 is provided with four air inlet cavities 102, four The natural air of the air inlet cavity 102 cools the circulating water in the dry cooling mechanism 8 and the wet cooling mechanism 9 by cross-flow cooling. The four air inlet cavities 102 are respectively connected with the water storage cavity 101. Table 2, the upper part of the support frame 1 is fixedly connected with an air extraction sleeve 3, the air extraction sleeve 3 is arranged with a small upper part and a large lower part, the air extraction sleeve 3 is communicated with the water storage cavity 101, and the upper part of the air extraction sleeve 3 is provided with a ...

Embodiment 2

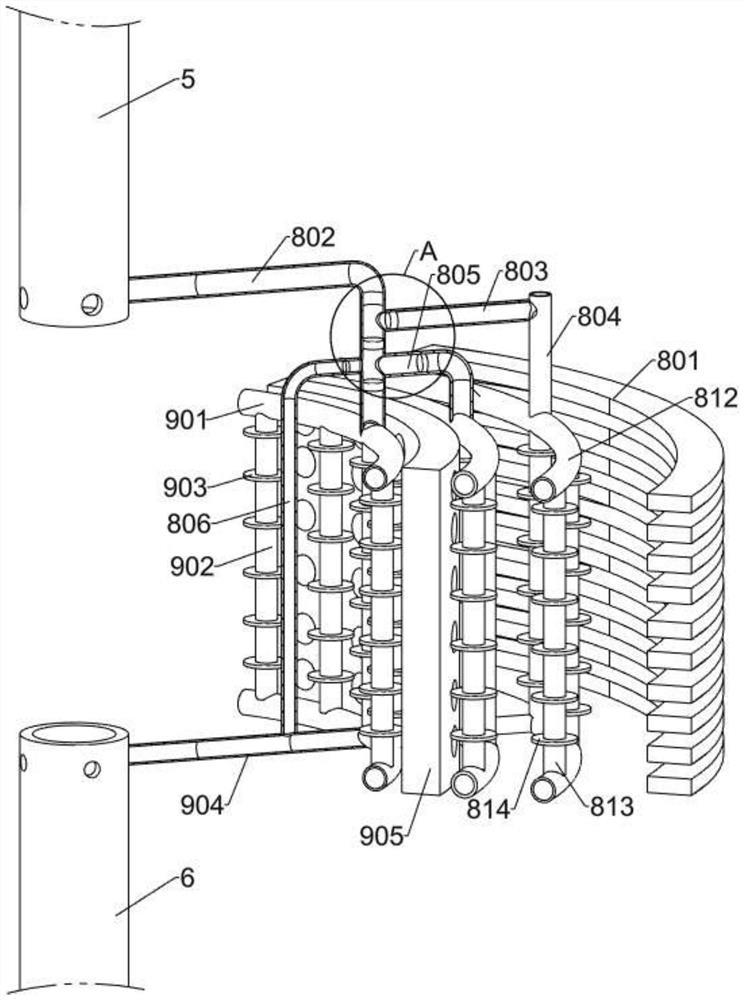

[0030] On the basis of Example 1, as image 3 and Figure 4 As shown, the dry cooling mechanism 8 includes a dry cooling shutter 801, the dry cooling shutter 801 is fixedly connected with the support frame 1, the dry cooling shutter 801 is located in the air inlet cavity 102 on the right side, the dry cooling shutter 801 is electrically connected with the console 2, and the dry cooling shutter 801 is used for In order to regulate the air intake volume of the four air inlet cavities 102, the lower part of the first water inlet pipe 5 is welded with a main water pipe 802, the main water pipe 802 is communicated with the lower part of the first water inlet pipe 5, and the upper side of the outer part of the main water pipe 802 is connected with a first water pipe. Dry cooling branch pipe 803, the outer part of the first dry cooling branch pipe 803 is connected with a second dry cooling branch pipe 804, the lower part of the main water pipe 802 is connected with a first L-shaped p...

Embodiment 3

[0037] On the basis of Example 2, as Image 6 and Figure 7 As shown, it also includes a discharge assembly 11. The upper part of the support frame 1 is provided with a discharge assembly 11 for hot air discharge. The sleeve 1101 is located on the outside of the exhaust sleeve 3. An exhaust cavity 1102 is formed between the exhaust sleeve 1101 and the exhaust sleeve 3. The upper part of the support frame 1 is provided with a number of exhaust holes 1103. The air cavity 1102 is communicated with the four air inlet cavities 102, and several air exhaust holes 1103 are located between the two dry cooling arc pipes 812 on the upper side. The air exhaust cavity 1102 in the discharge assembly 11 and several air exhaust holes The 1103 cooperates to discharge the hot air of this part of the natural wind to achieve a better cooling effect.

[0038] The discharge assembly 11 is used to discharge the natural wind whose temperature is slightly increased through the dry cooling mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com