Mold for preventing cracking of castings

A technology of castings and molds, which is applied in the field of molds to prevent cracking of castings, can solve the problems of low production efficiency, slow work of drawing cores, low production efficiency of molds, etc., and achieve the goal of improving production efficiency, improving exhaust effect, and improving processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

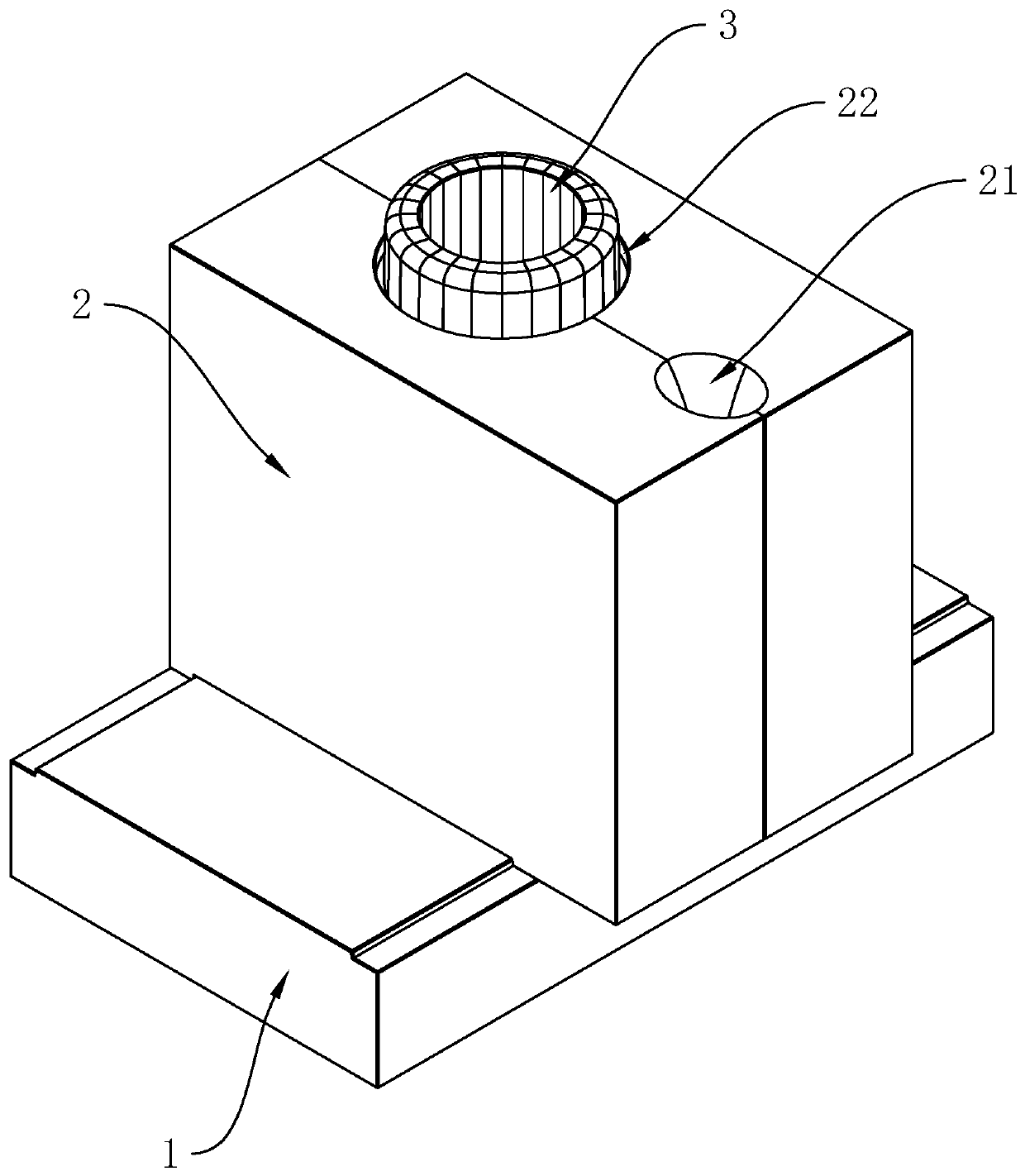

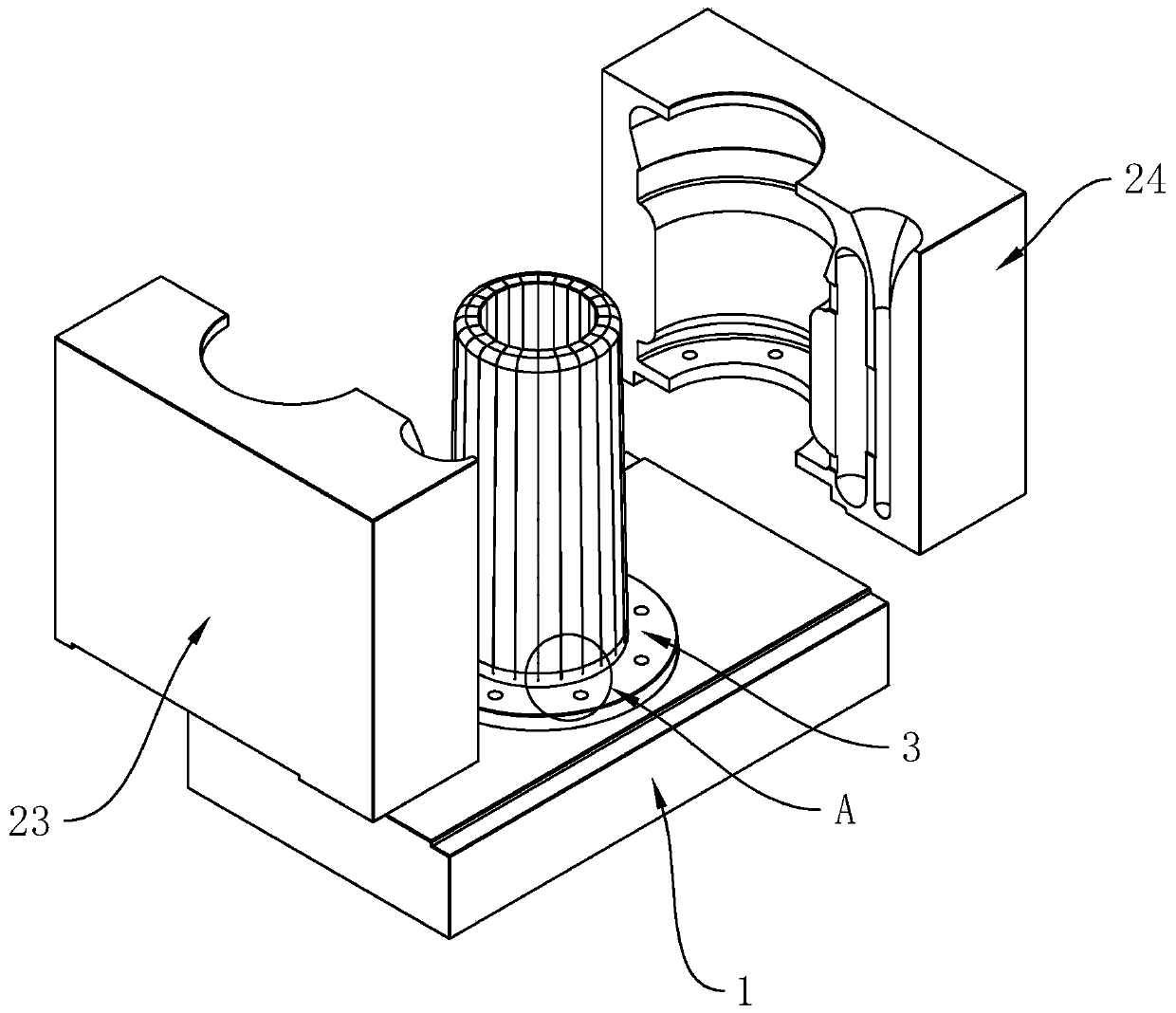

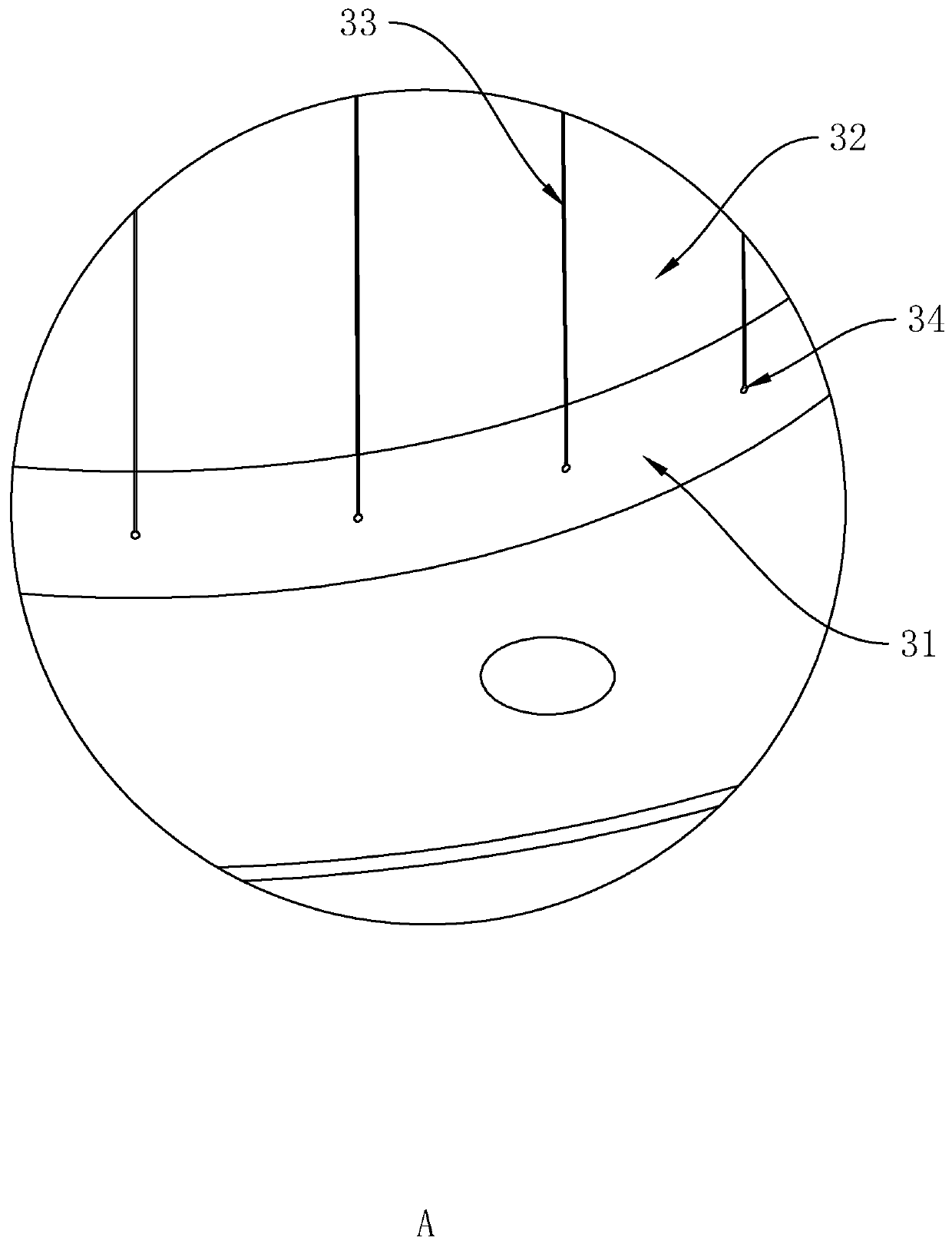

[0052] combine figure 1 with figure 2 As shown, it is a mold for preventing casting cracking disclosed by the present invention, including an outer mold for shaping the contour of the casting and a mold core 3 arranged inside the outer mold for forming the inner cavity of the casting; wherein the outer mold includes The lower mold 1 and the upper mold 2, the mold core 3 is arranged on the lower mold 1, the upper surface of the lower mold 1, the outer wall of the mold core 3 and the inner wall of the upper mold 2 are enclosed to form a cavity for casting molding, wherein, On the upper mold 2, two ends are respectively communicated with the outer wall and the inner wall of the upper mold 2 to be used for pouring the molten material into the runner 21 in the cavity; A riser 22 for air discharge in the mold cavity, the upper end of the mold core 3 stretches out of the riser 22 .

[0053] Among them, the upper mold 2 is divided into a left mold 23 and a right mold 24, and the ru...

Embodiment 2

[0063] Such as Figure 7 As shown, the difference from Embodiment 1 is that the shielding ring 4 is integrally formed with the lower mold 1. Specifically, the upper and lower ends of the lower mold 1 are respectively communicated with the upper and lower surfaces of the lower mold 1 and the inner diameter of the upper port is smaller than that of the lower port. The inner diameter of the stepped groove 12 is provided with a first stop ring 35 on the outer wall of the ring core 3 at the lower end of the core 3. When installing the core 3, only the first stop ring 35 needs to be clamped on the stop ring and make the upper end of the mold core 3 pass through the upper end of the stepped groove 12, and finally use bolts to connect the first limiting ring 35 and the shielding ring 4 together.

Embodiment 3

[0065] Such as Figure 8 As shown, the difference from Embodiment 1 is that the shielding ring 4 is set independently. Specifically, a second stop ring 36 arranged around the ring mold core 3 is provided at the lower end of the mold core 3 , and on the lower surface of the shielding ring 4 There is a card slot 41 set on the same circle center as the shielding ring 4 and communicated with the inner wall of the shielding ring 4. When installing the mold core 3, you only need to place the mold core 3 on the lower mold 1, and then set the shielding ring 4 on the mold core 3 and make the second limit ring 36 clamped in the slot 41, and finally use bolts to fix the blocking ring 4 and the lower mold 1 together.

[0066] Wherein, in this embodiment, the clamping groove 41 can also be provided on the lower mold 1 , or the clamping groove 41 is formed by surrounding the lower surface of the shielding ring 4 and the upper surface of the mold core 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com