An indirect air-cooling method for light-weight steel frame structure towers capable of saving water and preventing freezing

A steel frame, indirect technology, applied in the field of cooling towers, can solve the problems of consumption, long construction period, increased investment, etc., and achieve the effect of reducing manufacturing cost, good cooling effect and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

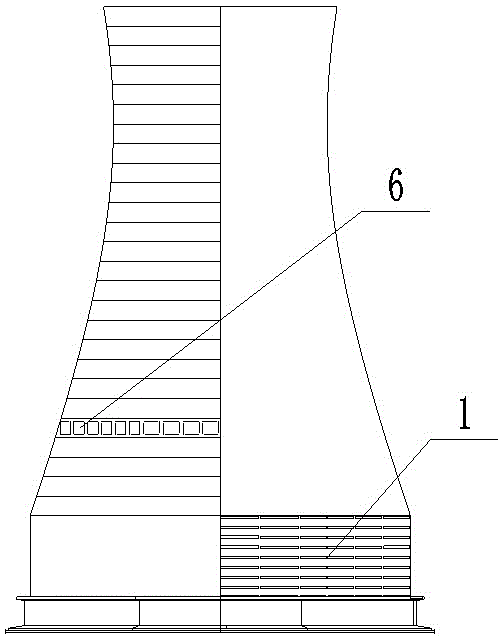

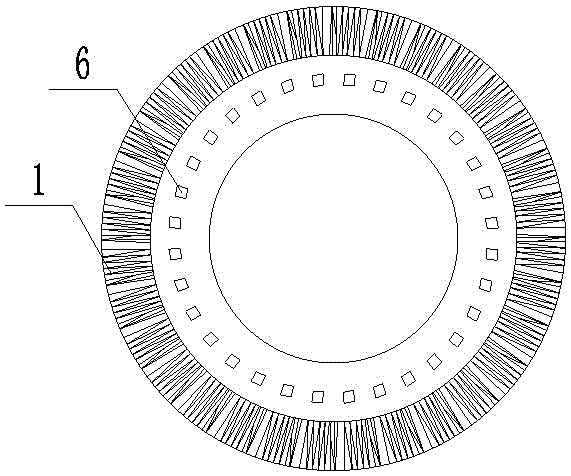

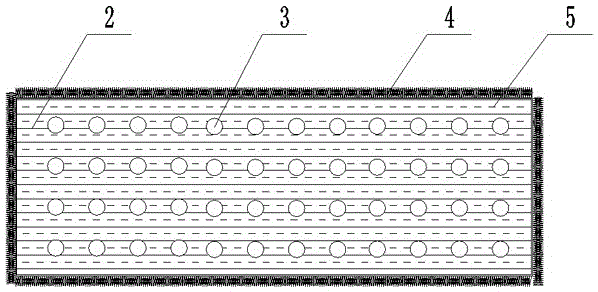

[0046] Such as figure 1 , figure 2 and image 3 As shown, a kind of indirect air-cooling method of light steel frame structure tower that can save water and prevent freezing of the present invention comprises the following process steps:

[0047] Step 1: Determine the structural parameters of the indirect air-cooled steel frame structure tower according to the power level;

[0048] The structural parameters refer to the parameters of traditional reinforced concrete structures;

[0049] The second step: according to the structural parameters obtained in the first step, determine the geometric size of the air duct;

[0050] The air duct adopts a hyperbolic shape, and the equation is:

[0051] the y 2 / a 2 -x 2 / b 2 = 1

[0052] x----the radius of the throat of the air cooling tower; m;

[0053] y - height of throat of air cooling tower; m;

[0054] According to the national standard GB / T50102-2003, the geometric dimensions of the air duct should satisfy the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com