Multi-depth slurry sampling device for cast-in-situ bored pile

A technology for bored piles and sampling devices, which is applied to sampling devices and other directions, can solve the problems of multi-depth sampling of bored piles, and achieves the advantages of reducing the difficulty of sampling operation, reducing construction costs, and improving sampling efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

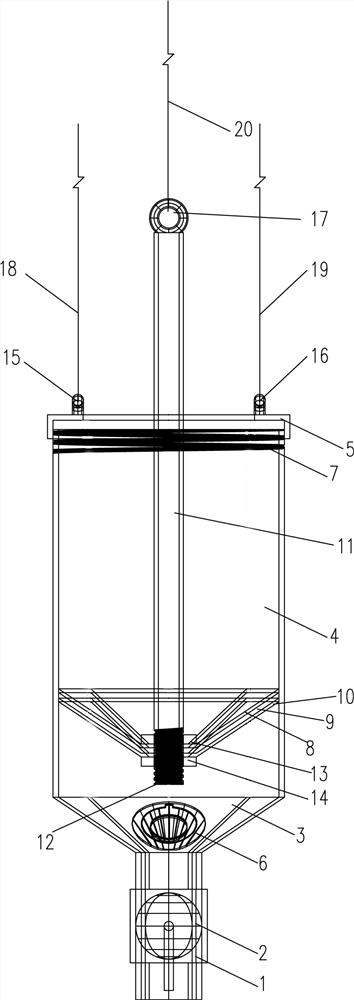

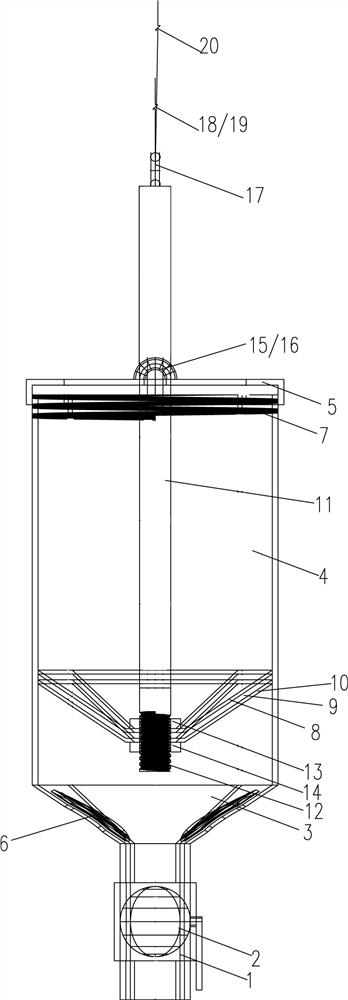

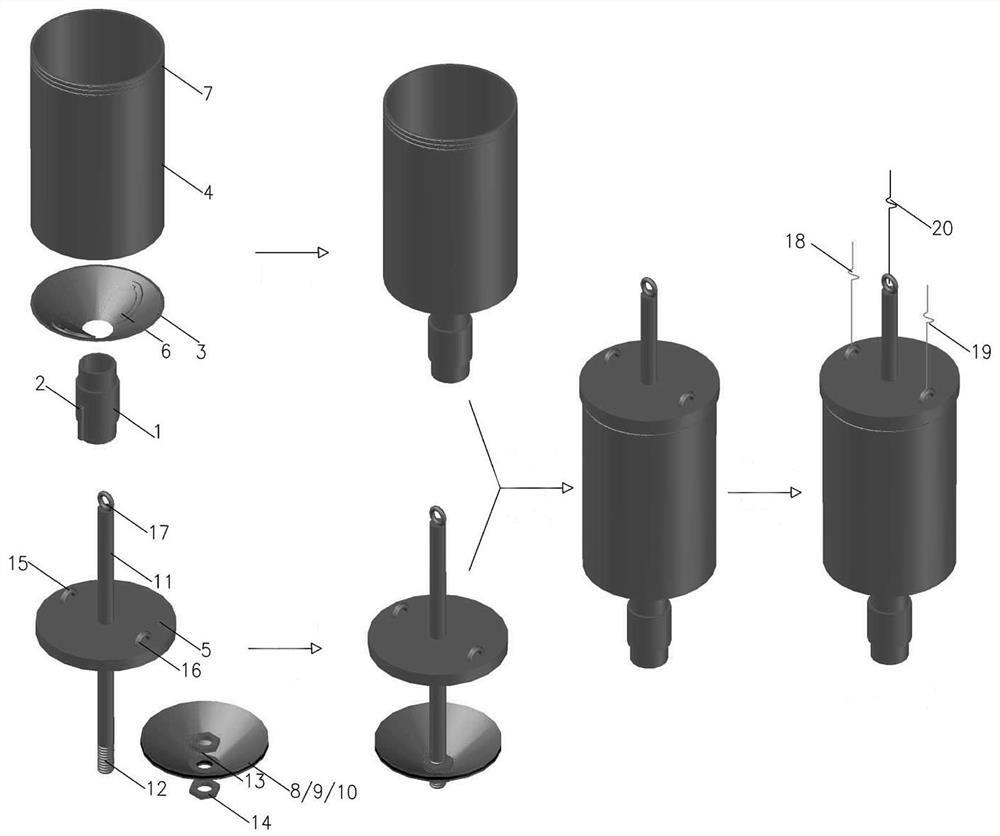

[0031] like Figure 1-13 Among them, a multi-depth mud sampling device for bored piles includes a cylinder body 4, a storage cavity 401 is arranged in the cylinder body 4, the storage cavity 401 is provided with a feed check valve and a discharge valve, and the storage cavity 401 is provided with a storage cavity 401. The slidable piston member is also provided with a main shaft rod 11, the piston member is connected with the main shaft rod 11, the upper end of the cylinder body 4 is provided with a first traction rope 18 and a second traction rope 19, and the upper end of the main shaft rod 11 is provided with a main shaft rod pull ring 17 , the pull ring 17 is connected with the cable 20 .

[0032] In a preferred solution, the upper end of the cylinder body 4 is provided with a cylinder cap 5, the cylinder body 4 is provided with a cylinder body thread 7, the cylinder body 4 is threadedly connected with the cylinder cap 5, and the cylinder cap 5 is provided with a first conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com