Manufacturing method of anode beam

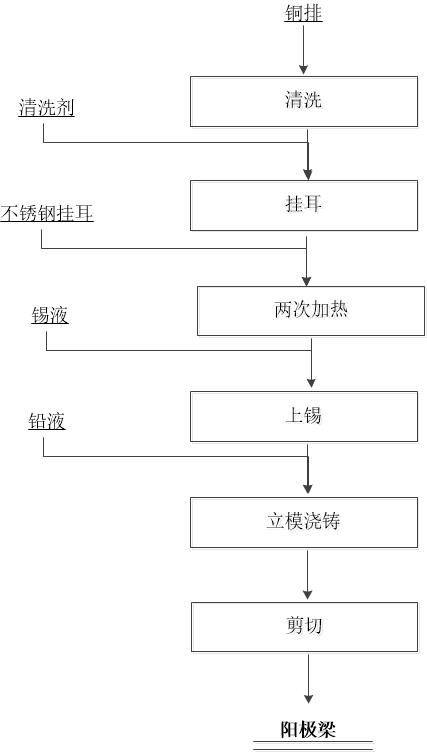

A manufacturing method and anode beam technology, applied in the coating, metal material coating process, hot-dip plating process, etc., can solve the problems of uneven tin hanging, unclean cleaning, environmental pollution, etc., and achieve easy automation of the whole process, Realize the effect of full process automation and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Clean the copper bars with the prepared cleaning agent. The cleaning agent is prepared from sulfuric acid 460ml / l, hydrochloric acid 10ml / l and sodium nitrate 110g / l. The cleaning temperature was 10°C, and the cleaning time was 4 minutes. Then, hang the cleaned anode beam on the stainless steel mounting lugs.

[0039] Hang the lifting ears with hooks, and heat the copper bar part of the anode beam twice. The first heating temperature is controlled at 80 °C, and the heating time is controlled at 60s; the second heating temperature is controlled at 150 °C, and the heating time is controlled at 60s.

[0040] Put tin on the copper bar part of the anode beam, hang the lifting lug with a hook, put the copper bar part of the anode beam into the tin liquid, the temperature of the tin liquid is 380 ℃, and the time is 20s.

[0041] The copper bar part of the anode beam is cast by vertical mold, and lead is cast. Hang the lifting ears with hooks, put the copper row part of the a...

Embodiment 2

[0044] Clean the copper bars with the prepared cleaning agent. The cleaning agent is prepared from sulfuric acid 505ml / l, hydrochloric acid 8.5ml / l and sodium nitrate 155g / l. The cleaning temperature was 20°C, and the cleaning time was 3 minutes. Then, hang the cleaned anode beam on the stainless steel mounting lugs.

[0045] Hang the lifting ears with hooks, and heat the copper bar part of the anode beam twice. The first heating temperature is controlled at 115°C, and the heating time is controlled at 50s; the second heating temperature is controlled at 175°C, and the heating time is controlled at 50s.

[0046] Put tin on the copper bar part of the anode beam, hang the lifting lug with a hook, put the copper bar part of the anode beam into the tin liquid, the temperature of the tin liquid is 390 ℃, and the time is 12.5s.

[0047]The copper bar part of the anode beam is cast by vertical mold, and lead is cast. Hang the lifting ears with hooks, put the copper row part of the ...

Embodiment 3

[0050] Clean the copper bars with the prepared cleaning agent. The cleaning agent is prepared from sulfuric acid 550ml / l, hydrochloric acid 7ml / l and sodium nitrate 200g / l. The cleaning temperature was 30°C, and the cleaning time was 2 minutes. Then, hang the cleaned anode beam on the stainless steel mounting lugs.

[0051] Hang the lifting lugs with hooks, and heat the copper bar part of the anode beam twice. The first heating temperature is controlled at 150°C, and the heating time is controlled at 40s; the second heating temperature is controlled at 200°C, and the heating time is controlled at 40s.

[0052] Put tin on the copper bar part of the anode beam, hang the lifting lug with a hook, put the copper bar part of the anode beam into the tin liquid, the temperature of the tin liquid is 400 ℃, and the time is 5s.

[0053] The copper bar part of the anode beam is cast by vertical mold, and lead is cast. Hang the lifting ears with hooks, put the copper row part of the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com