Complex equipment forward design scheme optimization method considering multi-source uncertainty

A design scheme and uncertainty technology, applied in design optimization/simulation, geometric CAD, gene model, etc., can solve problems such as design reciprocating cycles and multi-source uncertainty, and achieve the effect of reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

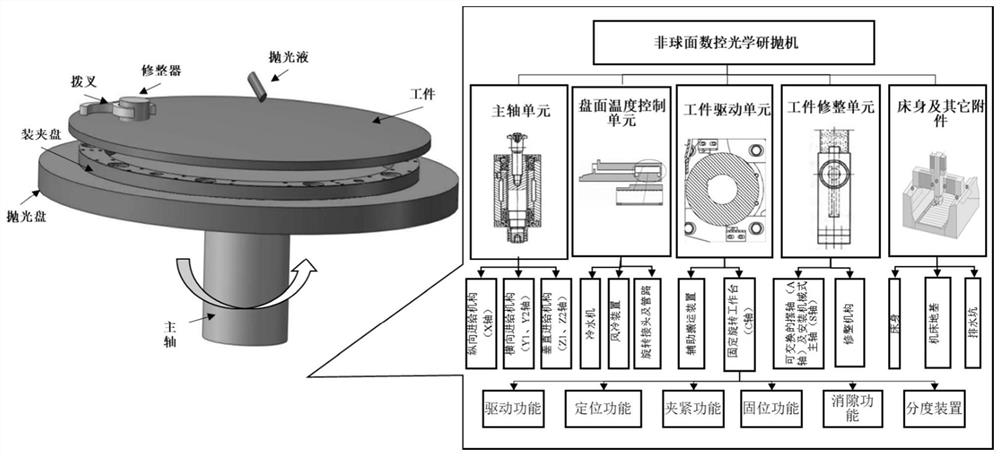

[0053] The present invention will be further described below by taking an aspherical optical polishing machine in complex equipment as an example.

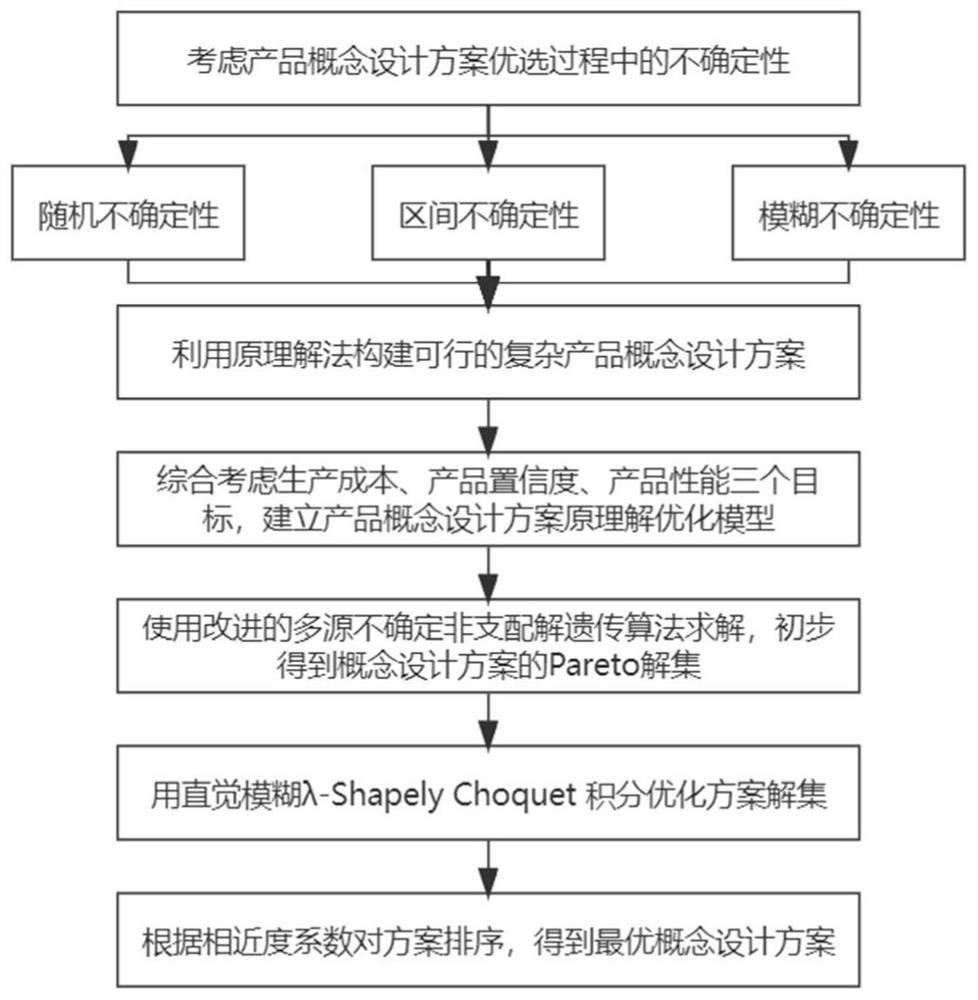

[0054] like figure 1 As shown, the present invention comprises the following steps:

[0055] 1) Considering the uncertainty in the optimization process of complex equipment, determine three uncertainty variables of each functional module in the forward design scheme of complex equipment. The three uncertainty variables are the module performance parameter P, the configuration cost C and the confidence Then, based on the three uncertainty variables of each functional module in the design scheme, the performance parameter responsivity function, interval cost function and fuzzy confidence function of the design scheme are established respectively;

[0056] The formula of the performance parameter responsivity function of the design scheme in step 1) is as follows:

[0057]

[0058]

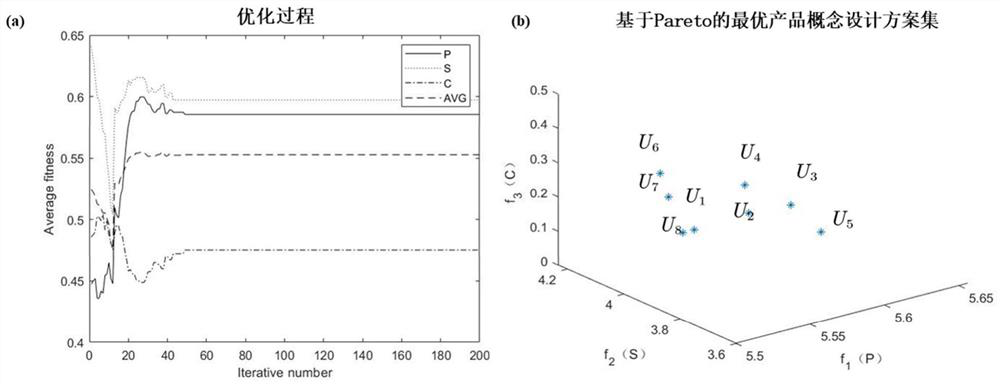

[0059] Among them, G(P) represents the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com