Anti-adhesion seed coating equipment

An anti-adhesion and coating technology, which is applied in the fields of seed coating/seed dressing, lighting and heating equipment, transportation and packaging, etc. Problems such as falling together and coating agent drop, to achieve the effect of increasing the diversity and convenience of use, stable and convenient conveying work, and uniform mixing as a whole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

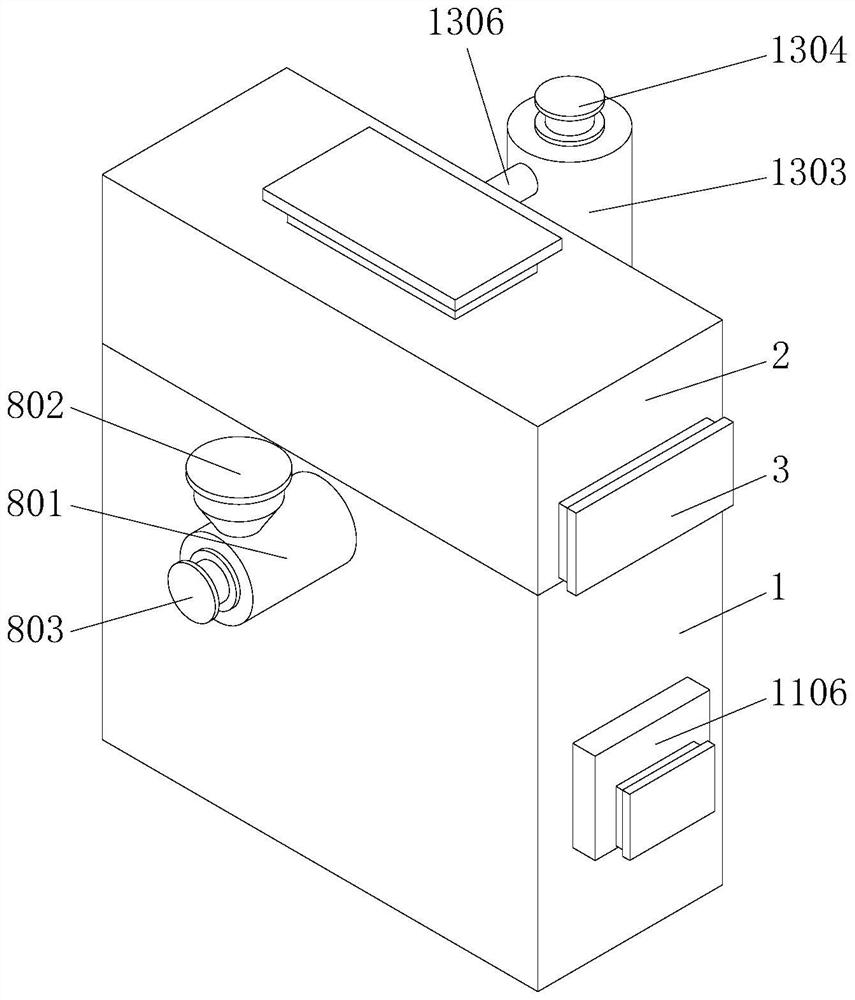

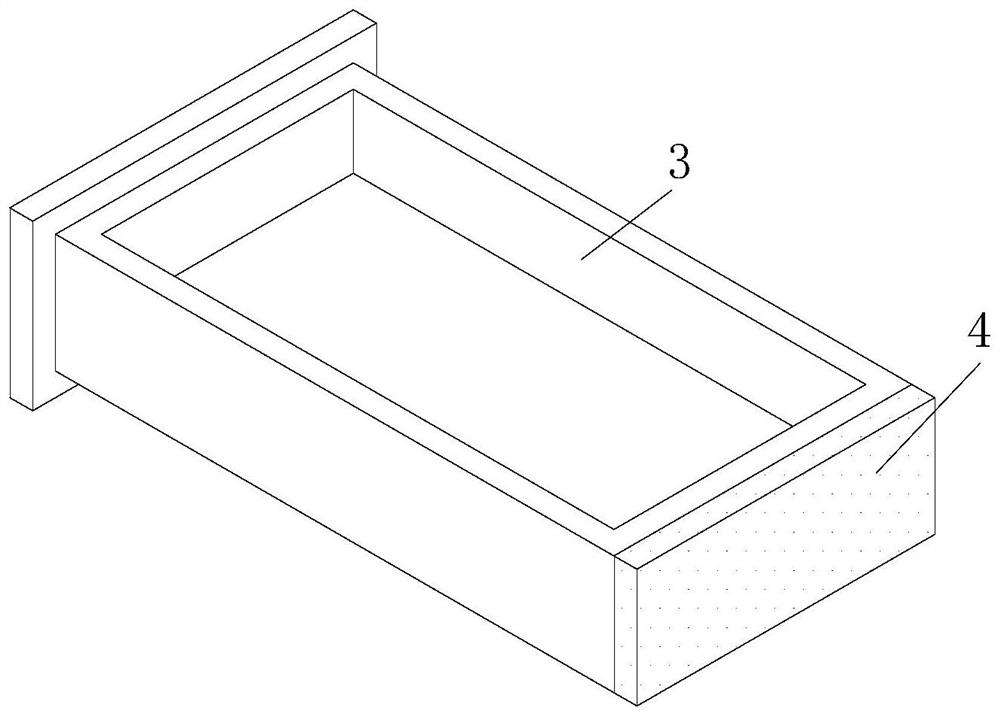

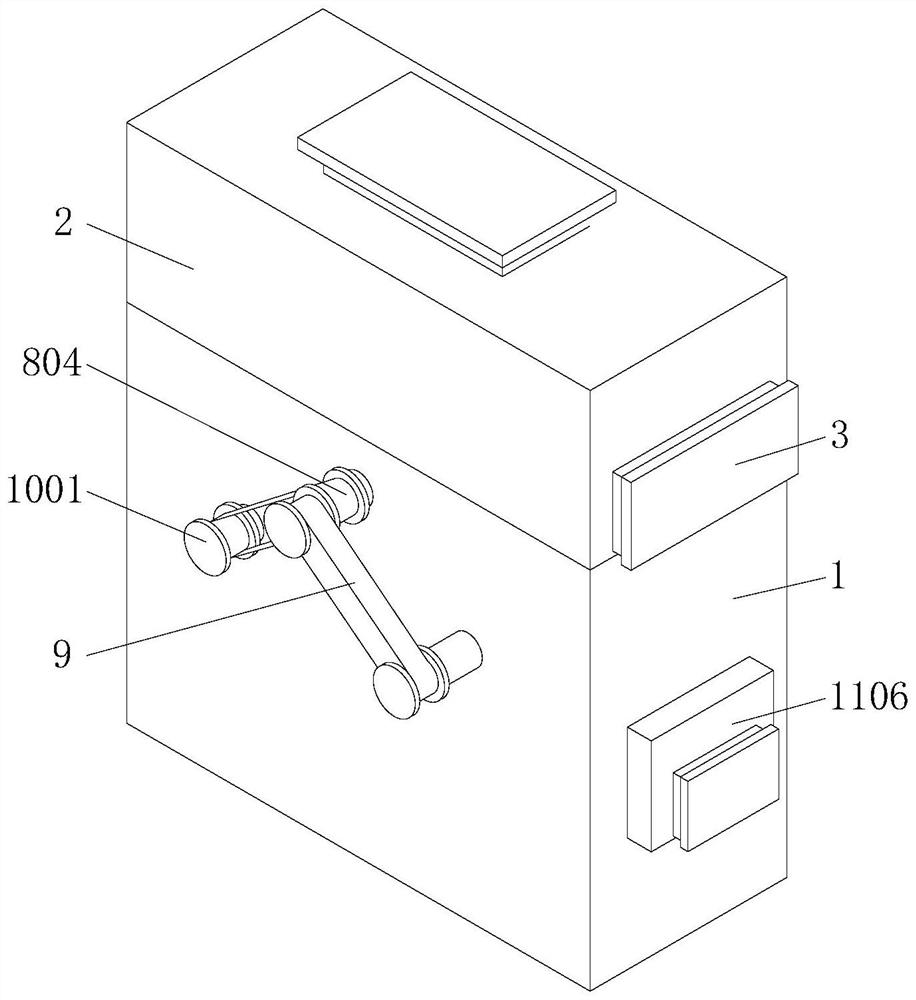

[0036] like Figure 1-8 As shown, an anti-adhesion seed coating equipment includes a device casing 1 and a feeding trough 5. A storage box 2 is welded and fixed to the top of the device casing 1, and a collection frame 3 is connected to the storage box 2 with a limit sliding connection. The collecting frame 3 is screwed with the magnetic plate 4, the bottom end of the storage box 2 is screwed with the fixing plate 6, and the feeding slot 5 runs through the bottom end of the storage box 2 and the top of the fixing plate 6. A feeding chute 7 runs through the bottom end, a stirring and conveying assembly 8, an equal amount feeding assembly 10, a preheating cleaning assembly 11 and a coating assembly 12 are installed in the device shell 1, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com