Porous ceramic heating element and preparation method thereof

A technology of porous ceramics and heating elements, applied in the field of atomizers, can solve the problems of carbon deposition in the heating wire, single porosity, small heating area, etc., achieve the effect of uniform temperature field and reduce the probability of internal carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

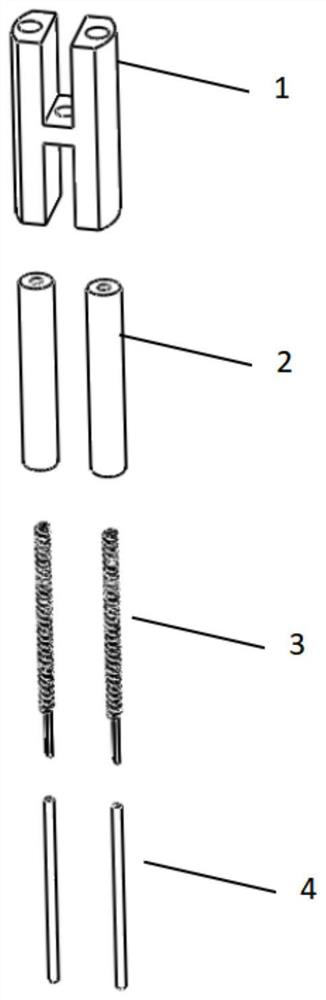

[0042] The present invention also provides a preparation method of a porous ceramic heating element, comprising the following steps:

[0043] A porous ceramic body and at least one porous ceramic tube are prepared by a high temperature sintering method, and the porous ceramic body has at least one through hole;

[0044] assembling the porous ceramic tube in the through hole of the porous ceramic body;

[0045] Assembling the metal heating core wound into a spring shape in a porous ceramic tube to form the porous ceramic heating body;

[0046] The assembled porous ceramic heating element is sintered.

[0047] Further, before the step of assembling the metal heating core wound into a spring shape in the porous ceramic tube, the steps of forming the porous ceramic heating body also include:

[0048] welding the first metal wire and the second metal wire into a metal heating core;

[0049] The second metal wire is put into the insulating ceramic tube sintered at high temperatur...

Embodiment 1

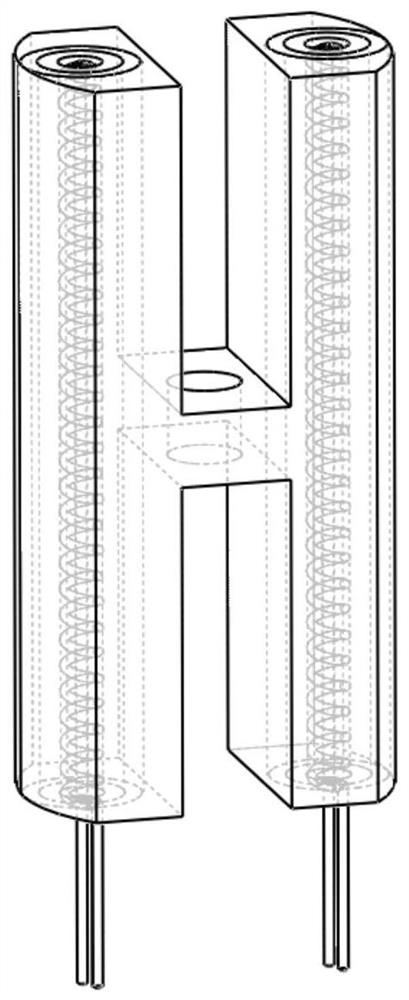

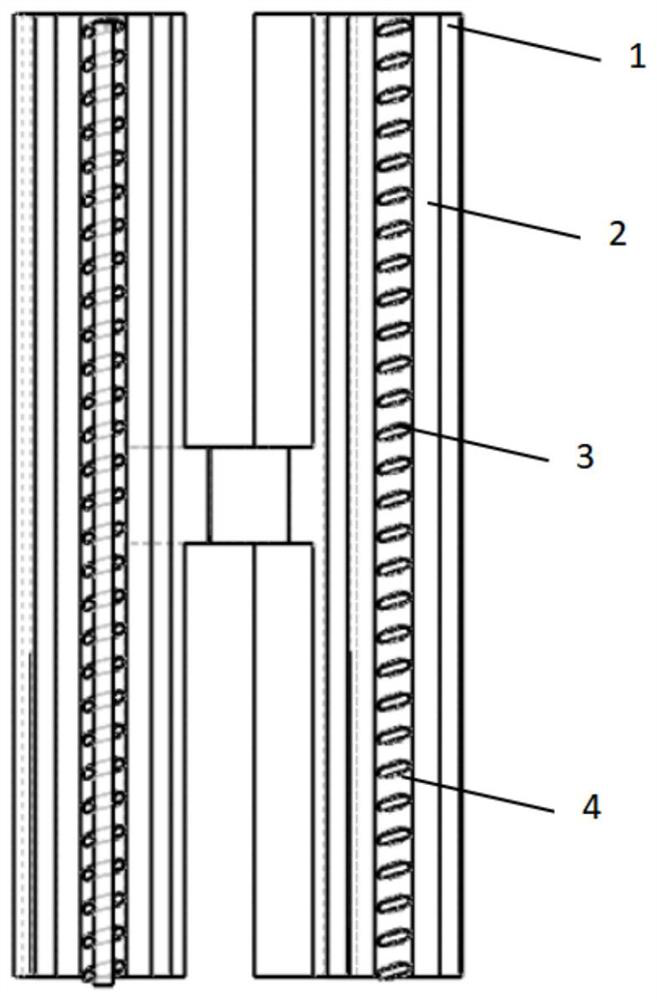

[0052] 1. The porous ceramic body is prepared by high-temperature sintering. Its porosity is 55%, the average pore diameter is 100-150 μm, and its shape is “H” type, with through holes in symmetrical positions on both sides, and air conduction holes in the center.

[0053] 2. The porous ceramic tube is prepared by high temperature sintering, the porosity is 60%, and the average pore diameter is 8-15 μm.

[0054] 3. Assemble the porous ceramic tube in the two through holes of the porous ceramic body, and use the porous ceramic glue to fix it.

[0055] 4. Weld the two metal materials of the metal heating core into a whole using a laser welding machine.

[0056] 5. The insulating ceramic tube is prepared by high temperature sintering, the second metal wire of the metal heating core is put into the insulating ceramic tube, and then the two are put into the porous ceramic tube.

[0057] 6. Use porous ceramic glue to fix the interface between the metal heating core and the porous c...

Embodiment 2

[0061] 1. The porous ceramic body is prepared by high-temperature sintering. Its porosity is 55%, the average pore diameter is 100-150 μm, and its shape is “U” shape, with through holes in symmetrical positions on both sides, and air conduction holes in the center.

[0062] 2. The porous ceramic tube is prepared by high temperature sintering, the porosity is 60%, and the average pore diameter is 8-15 μm.

[0063] 3. Assemble the porous ceramic tube in the two through holes of the porous ceramic body, and use the porous ceramic glue to fix it.

[0064] 4. Wind the nickel-chromium-silicon alloy metal heating core into a spring shape and place it in a porous ceramic tube.

[0065] 5. Use porous ceramic glue to fix the interface between the metal heating core and the porous ceramic tube.

[0066] 6. Place the assembled heating element in a muffle furnace at 400-800°C for sintering to complete the debinding and sintering of the porous ceramic glue, and complete the preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com