Anatomical biomechanical type 3D printing humerus greater tubercle cleavage fracture guider

A biomechanical and 3D printing technology, applied in the field of medical equipment, can solve the problems of weak fixation biomechanics, wear-through, and fixation strong protrusions to be improved, so as to increase the change of fixation angle and biomechanics, promote reset and fixation, and improve The effect of medical diagnosis and treatment level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

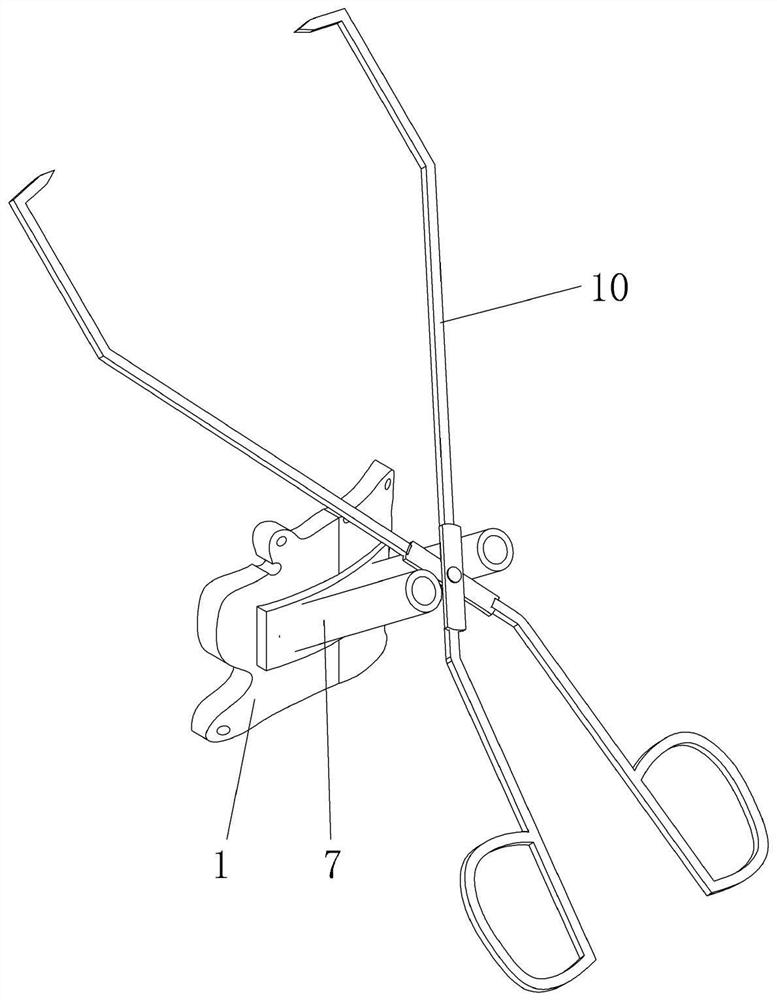

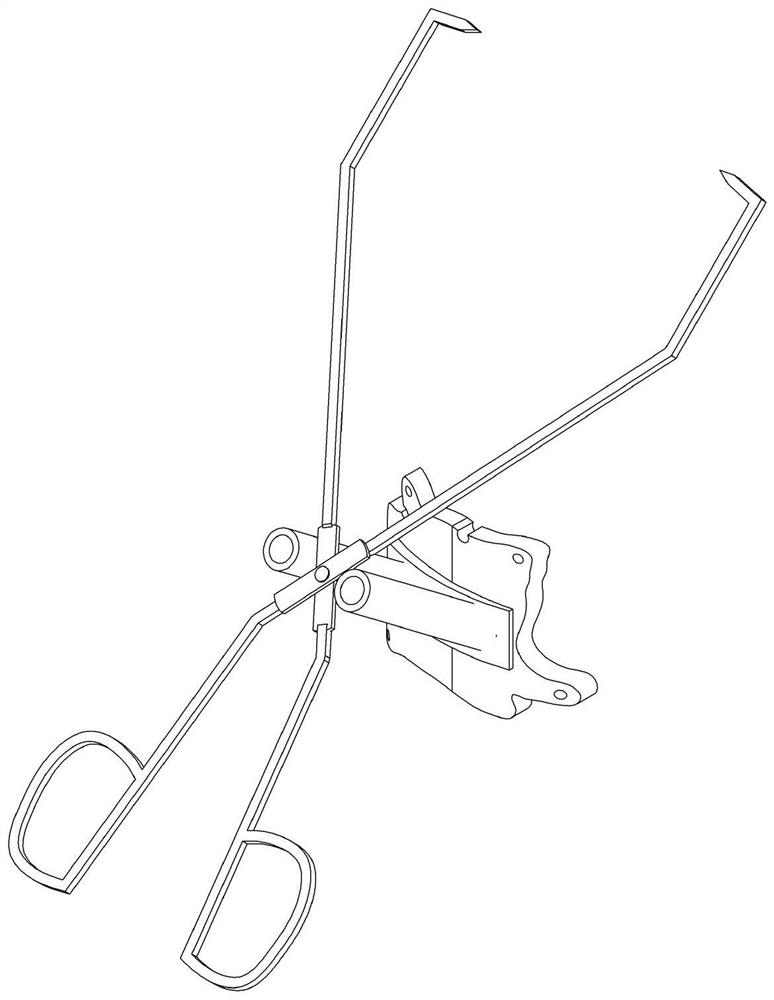

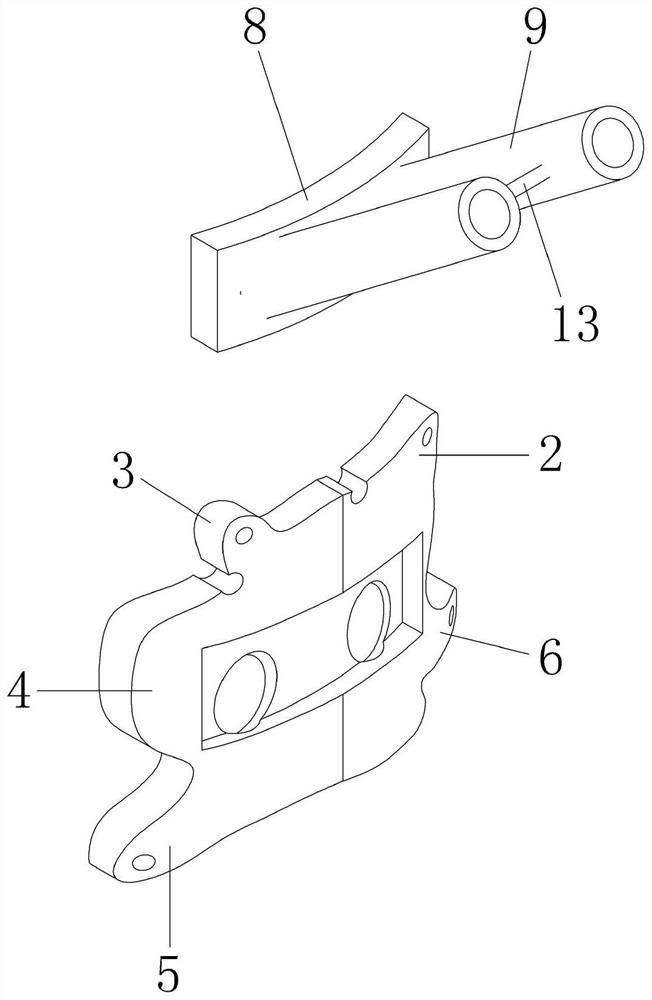

[0028] like figure 1 , figure 2 As shown, an anatomical and biomechanical 3D printed humerus greater tuberosity split fracture guide includes a guide plate 1 with an arc-like structure made based on the anatomical structure of the greater tubercle, and the guide plate 1 is integrally formed with a guide plate 1 along the circumferential direction. The first bulge 2 and the second bulge 3 made from the anatomical structure of the superior muscle, the third bulge 4 made based on the anatomical structure of the infraspinatus muscle, and the fourth bulge made based on the anatomical structure of the teres minor 5. The fifth protrusion 6 made based on the anatomical structure of the intertuberous sulcus.

[0029] like image 3 , Figure 4 As shown, a biomechanical guide sleeve portion 7 is detachably connected to the outside of the guide plate 1. The biomechanical guide sleeve portion 7 in this embodiment includes a clip 8 that is detachably connected to the guide plate 1. One...

Embodiment 2

[0034] The difference between the second embodiment and the first embodiment is that a vertical rod is welded at the lower part of the hinge part 11, and a sinker that can be adapted to the vertical rod is processed in the vertical direction in the middle of one side of the guide sleeve 9 on the card board 8. During use, the head of the towel clamp 10 clamps the acromion position, and then the vertical rod is placed in the sink cavity on the clamping plate 8 to realize the positioning of the clamping plate 8 .

[0035] The specific implementation process is as follows:

[0036]Taking Embodiment 1 as an example to illustrate, after the fracture fragment is reset, the guide plate 1 is placed on the body surface position corresponding to the greater tuberosity of the humerus, and the first protrusion 2 and the second protrusion 3 can be used to identify the supraspinatus muscle dissection. Structure, the 3rd protrusion 4 can be used to identify the infraspinatus muscle dissection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com