Device and method for replacing filter element of industrial water purifier based on industrial manipulator

A technology for industrial manipulators and water purifiers, which is applied in manipulators, manufacturing tools, hand-held tools, etc., can solve the problems of falling and broken filter elements, unstable clamping, and heavy filter elements, so as to achieve convenient clamping and replacement, and easy clamping The effect of holding fixed and improving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

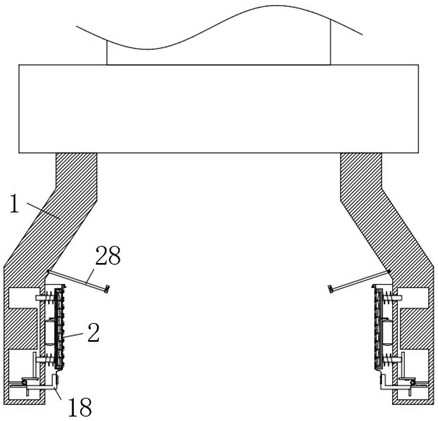

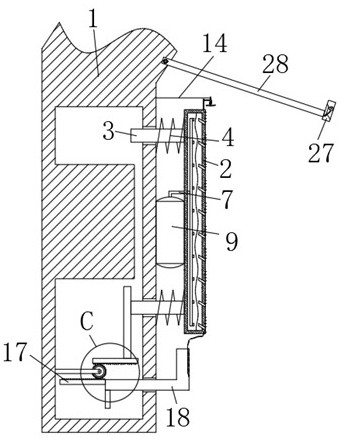

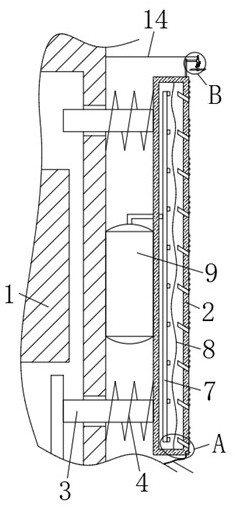

[0038] refer to Figure 1 to Figure 9 The embodiments of the device and method for replacing the filter element of an industrial water purifier based on an industrial manipulator of the present invention will be further described.

[0039] An industrial water purifier filter element replacement device based on an industrial manipulator includes a mechanical gripper 1. The mechanical gripper 1 is provided with a splint 2 on one side that is close to each other, and a connecting rod 3 is fixed symmetrically at one end of the splint 2 away from each other. , the ends of the connecting rods 3 that are far away from each other are respectively inserted into the mechanical grippers 1 on both sides, the connecting rods 3 are sleeved with a first spring 4, and the ends of the first springs 4 that are close to each other and are far away from each other are respectively The splint 2 and the mechanical gripper 1 are fixedly connected, the ends of the splint 2 that are close to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com