Cab framework, cab and combine harvester

A cab and skeleton technology, applied in the field of agricultural machinery combine harvesters, can solve the problems of low strength of welded structure, easy to shake, limited view of downward observation, etc., to reduce the risk of overturning, and to achieve high structural rigidity and strength. , the effect of good front visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

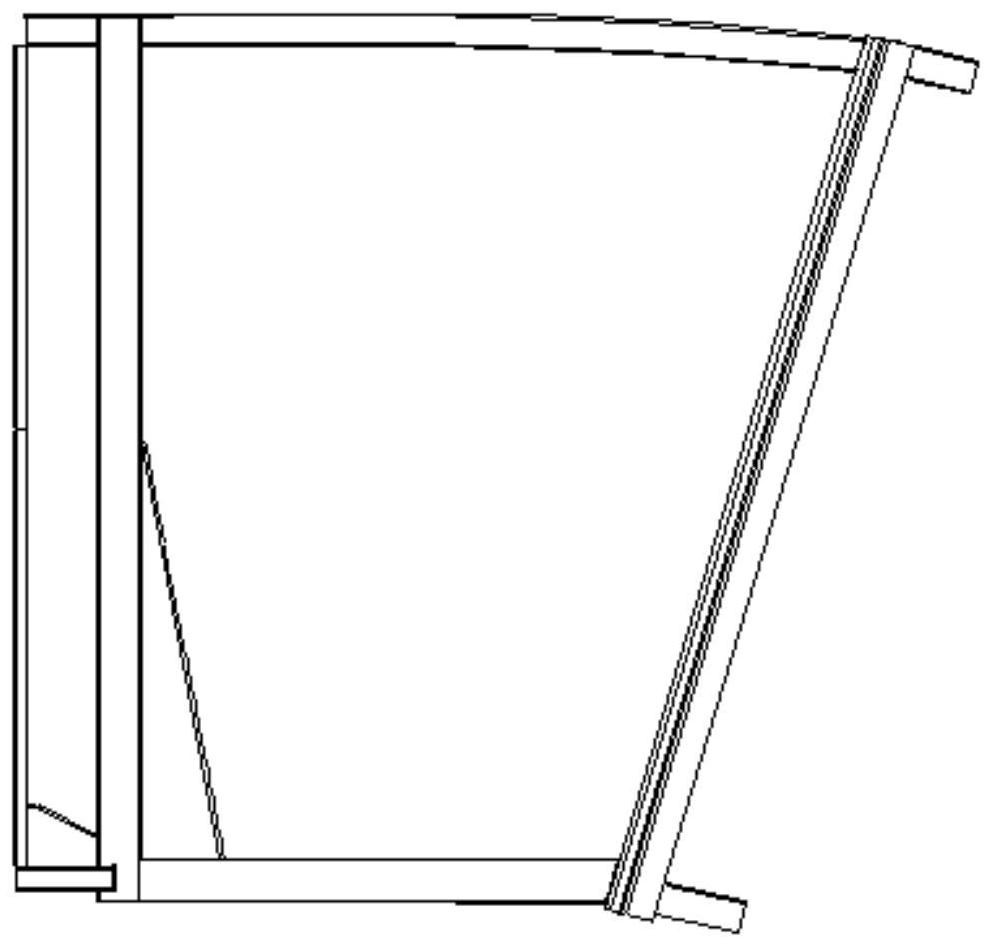

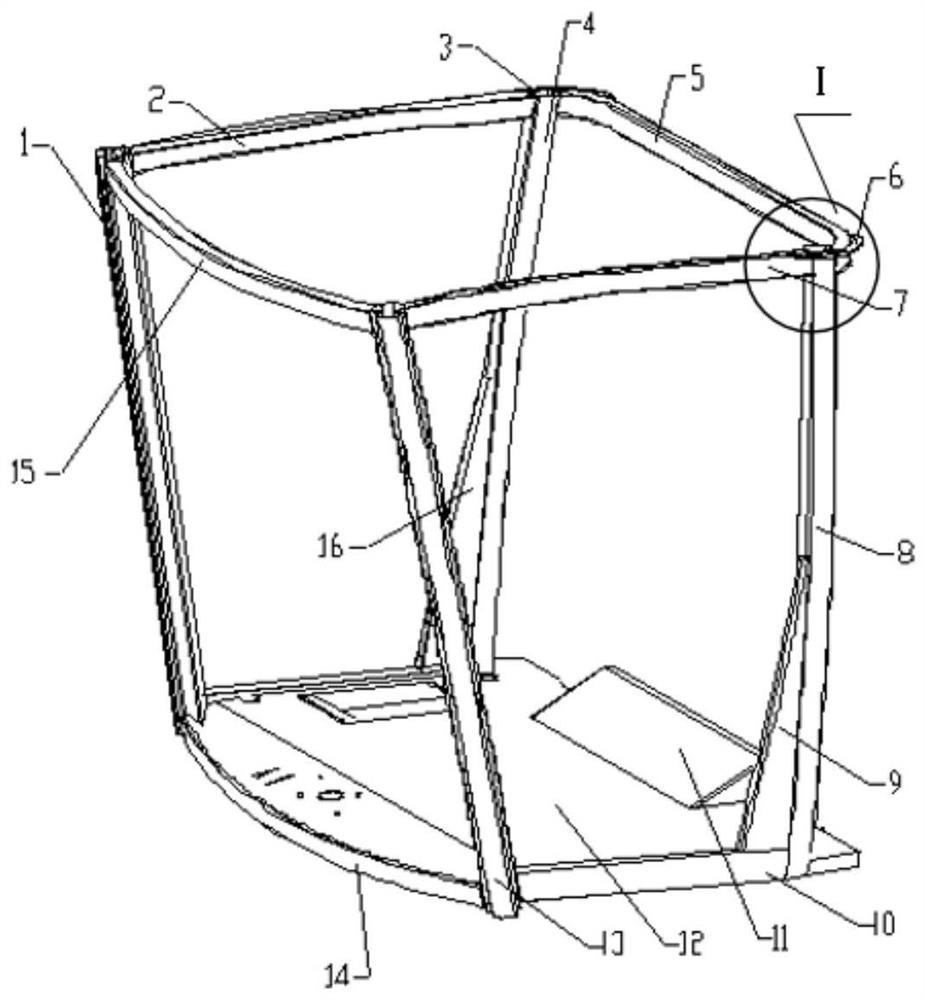

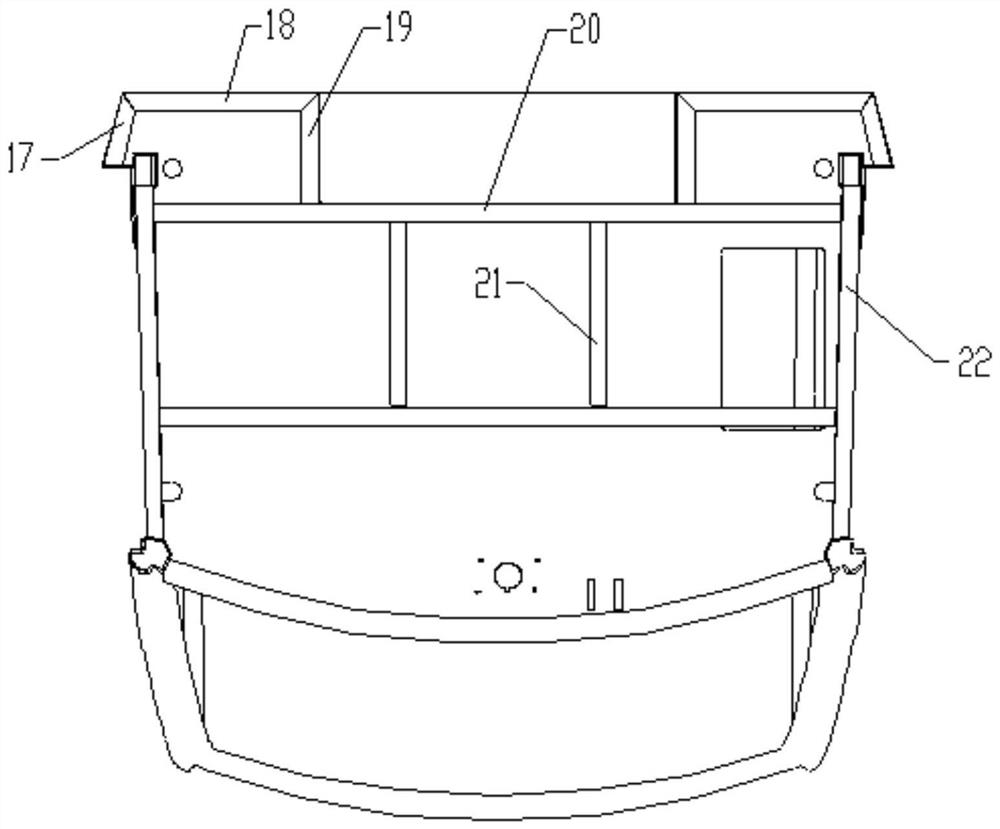

[0037] This embodiment discloses a cab frame and a combine harvester. like Figure 4 , Figure 5 As shown, the cab frame 23 of the combine harvester provided by the present invention is a welded assembly, combined with Image 6 , the frame 23 includes the cab main frame 36 and the rear lower sealing plate 24, the rear upper sealing plate 25, the rear top sealing plate 26, the reinforcing rib one 27, the reinforcing rib two 28, the control box mounting seat 29, the shock absorption bearing one 30 , shock-absorbing support two 31, shock-absorbing support three 32, shock-absorbing support four 33, main seat mounting seat 34, sub-seat mounting seat 35; , the top of which is welded un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com