Mask recycling equipment

A technology for recycling equipment and masks, which is applied in the field of masks, can solve the problems of insufficient safety and inconvenience, and achieve the effects of easy collection, avoiding virus transmission, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

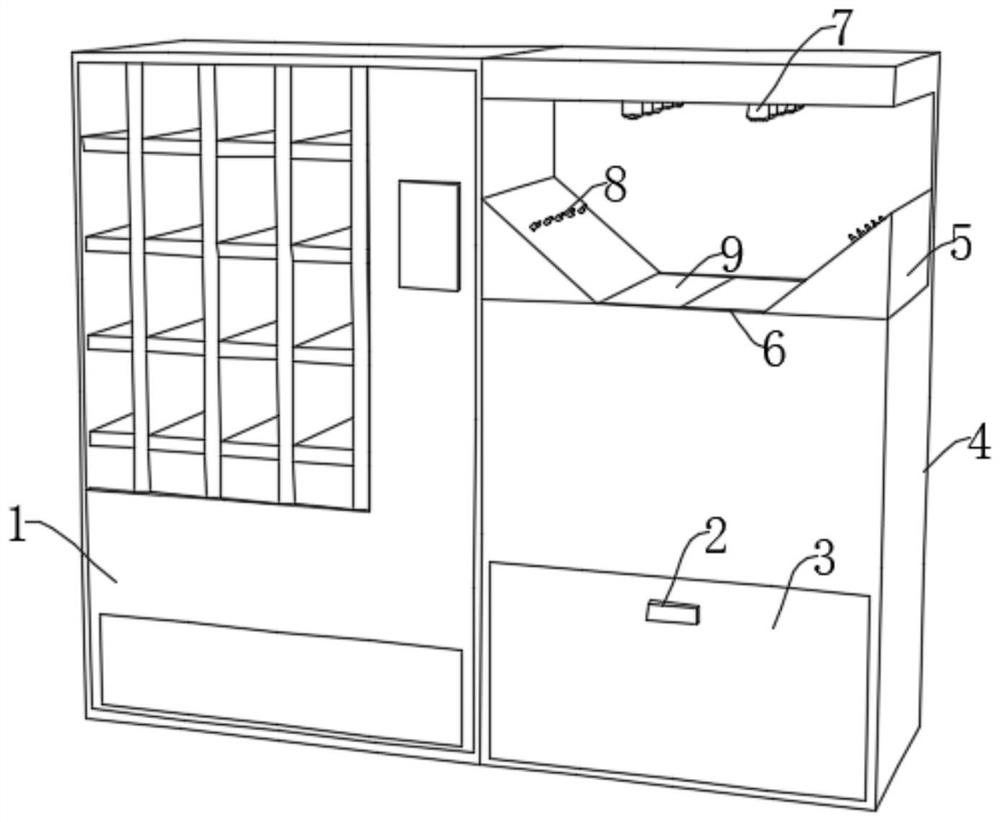

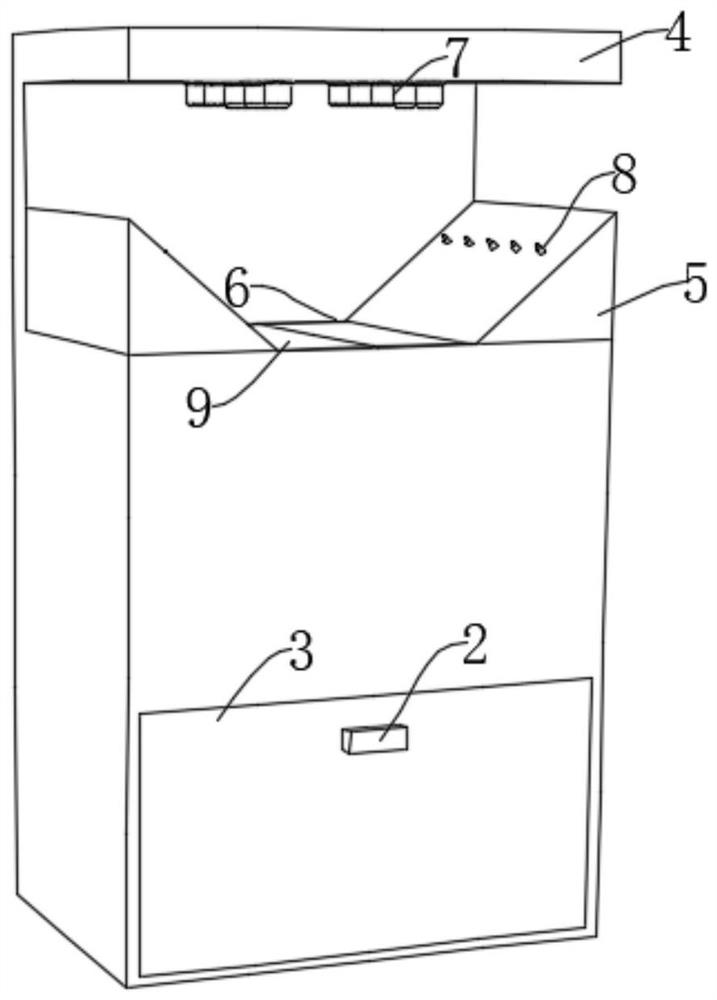

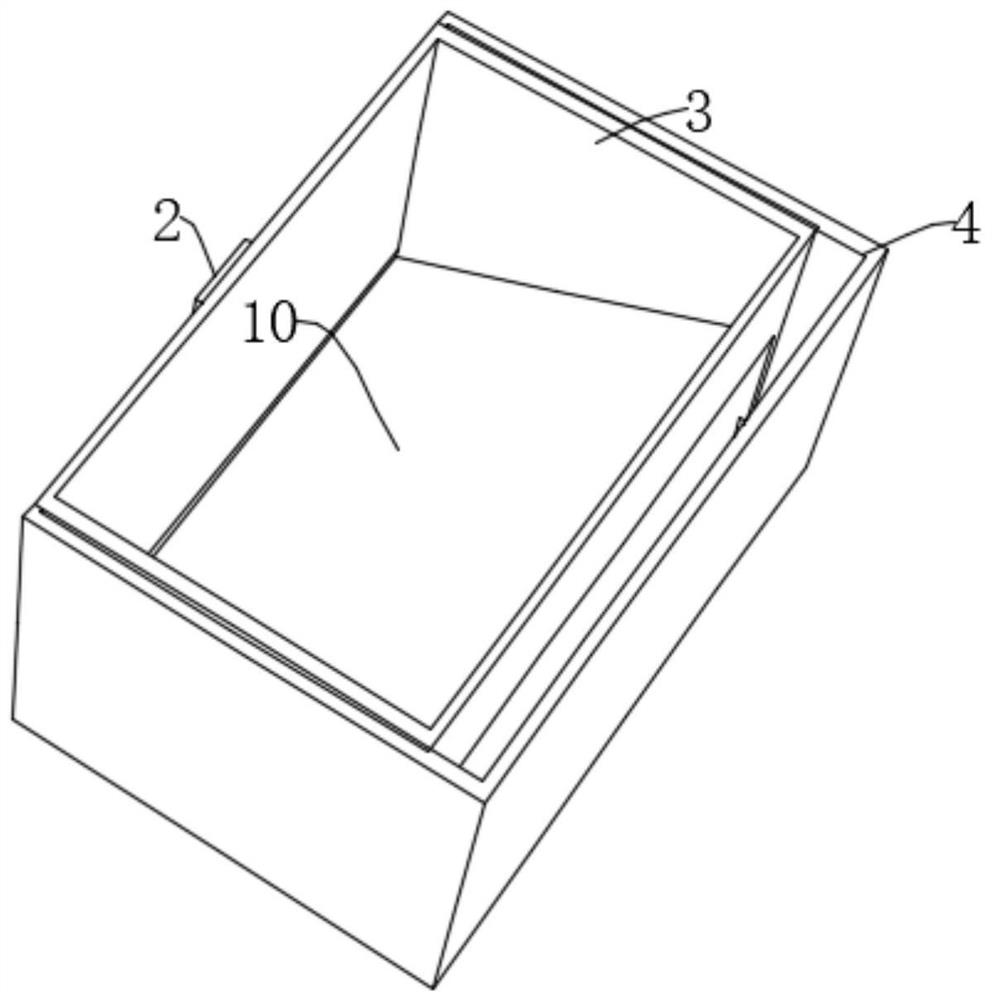

[0030] refer to Figure 1-Figure 6 , a mask recycling equipment, including a rectangular box 4, the top of the rectangular box 4 is provided with a drop opening 6, the inside of the drop opening 6 is fixedly connected with a rotating shaft 13, both sides of the rotating shaft 13 are rotatably connected with baffles 9, the rectangular box 4 The inner wall of one side is provided with a rotating assembly for driving the baffle 9 to rotate;

[0031] The inner walls on both sides of the rectangular box 4 are fixedly connected with trapezoidal plates 17, and the inner wall on one side of the rectangular box 4 is provided with a conveying assembly for conveying masks;

[0032] The bottom inner wall of the rectangular box 4 is provided with a collection assembly for collecting masks.

Embodiment 2

[0034] refer to Figure 1-Figure 6 , a mask recycling equipment, including a rectangular box 4, the top of the rectangular box 4 is provided with a drop opening 6, the inside of the drop opening 6 is fixedly connected with a rotating shaft 13, both sides of the rotating shaft 13 are rotatably connected with baffles 9, the rectangular box 4 The inner wall of one side of the box is provided with a rotating assembly for driving the baffle 9 to rotate. The rotating assembly includes a fixed plate 22 fixedly connected to the inner wall of one side of the rectangular box 4. The top of the fixed plate 22 is fixedly connected with an electric push rod 20. The electric push rod 20 The piston rod is fixedly connected with a sliding block 23, the sliding block 23 is slidably connected with one side of the inner wall of the rectangular box 4, both sides of the sliding block 23 are fixedly connected with a first connecting block 26, and the bottom of the baffle 9 is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com