Pervious concrete binder and pervious concrete

A technology of permeable concrete and binder, which is applied in the field of permeable concrete binder and permeable concrete, and can solve the problems of poor water permeability and high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

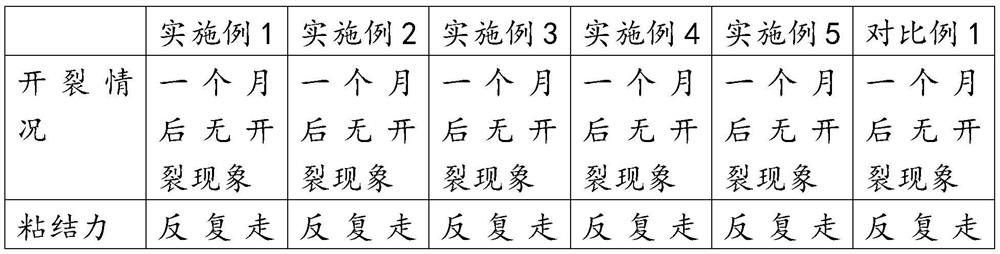

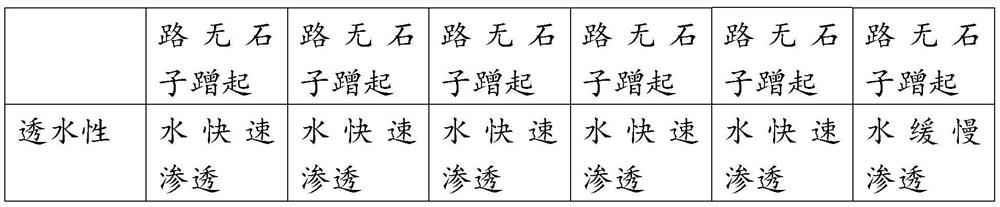

Examples

preparation example Construction

[0011] The preparation method of the permeable concrete binder is as follows: put each component into a mixer according to the proportion, mix and stir for 30 minutes, and then pack it into a bag after stirring evenly.

[0012] By weight percentage, the permeable concrete comprises 10%-20% cement, 2%-4% binder and 80%-90% stone, and the binder is the above-mentioned permeable concrete binder. Further optimally, the permeable concrete comprises: 14.2% cement, 2.5% binder and 83.3% stone.

[0013] The preparation method of permeable concrete is as follows: the cement, stone and binder are mixed and used in proportion. The permeable concrete can be prepared on the construction site, and put into construction immediately after the preparation is completed, so as to avoid the concrete being placed for a long time.

Embodiment 1

[0016] By weight percentage, the pervious concrete binder includes 20% fly ash, 35% calcium silica powder, 20% calcium chloride, 5% cellulose, 15% resin rubber powder and 5% retarder.

[0017] Pervious concrete consists of 14.2% cement, 2.5% binder and 83.3% stone.

Embodiment 2

[0019] By weight percentage, the permeable concrete binder includes 35% fly ash, 30% silica calcium powder, 15% calcium chloride, 5% cellulose, 12% resin rubber powder and 3% retarder.

[0020] Pervious concrete consists of 15% cement, 3.0% binder and 82% stone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com