Centrifugal separation type aronia melanocarpa Baijiu processing and brewing equipment

A technology of centrifugal separation and rowan, which is applied in the field of centrifuge-separated rowan liquor processing and brewing equipment, which can solve the problems of unsqueezed rowan and inconvenient cleaning of rowan residue, and achieve convenient crushing , easy to clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

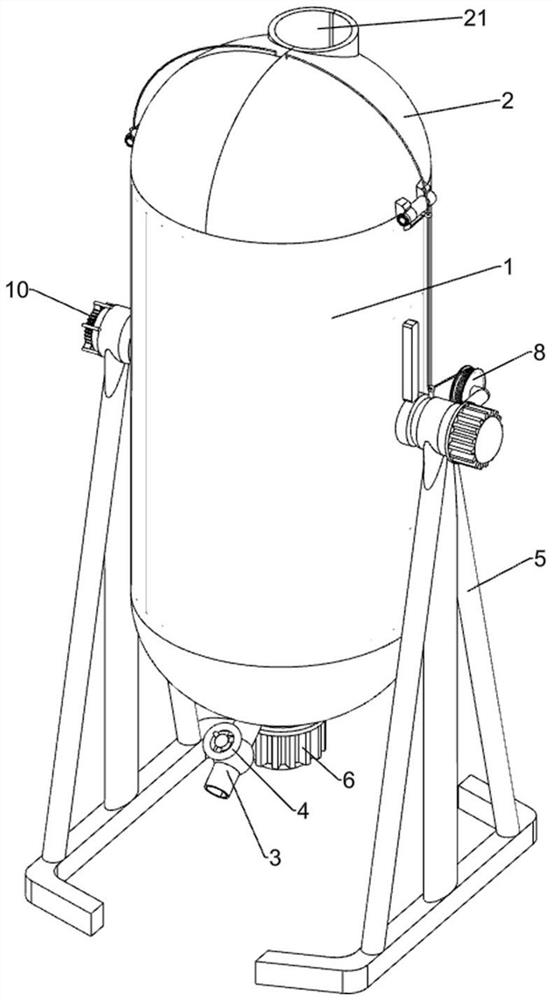

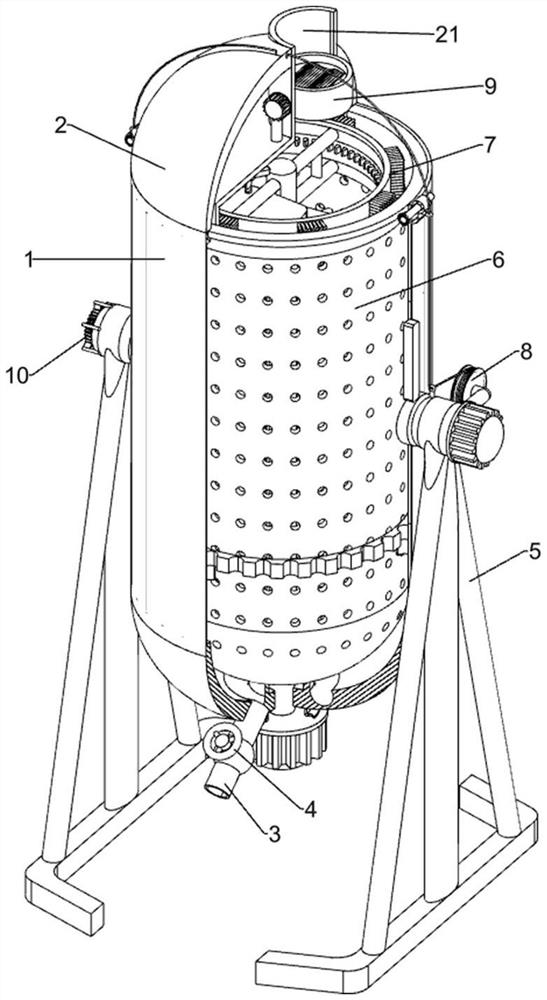

[0036] A centrifugal separation type black fruit and arborum liquor processing and brewing equipment, including a brewing barrel 1, a lid 2, a feeding port 21, a discharging pipe 3, a valve 4, a rotating mechanism 5 and a throwing mechanism 6, see Figure 1-Figure 5 As shown, the upper left and right sides of the brewing barrel 1 are rotatably connected with lids 2, the two lids 2 both cover the top of the brewing barrel 1, a feeding port 21 is opened between the two lids 2, and the front side of the bottom of the brewing barrel 1 The middle part is connected with a discharge pipe 3 and communicated. Under the action of the discharge pipe 3, the juice of the black fruit can be discharged. The discharge pipe 3 is rotatably connected with a valve 4, and the brewing barrel 1 is provided with a rotating mechanism 5. The brewing barrel 1 is provided with a throwing mechanism 6 .

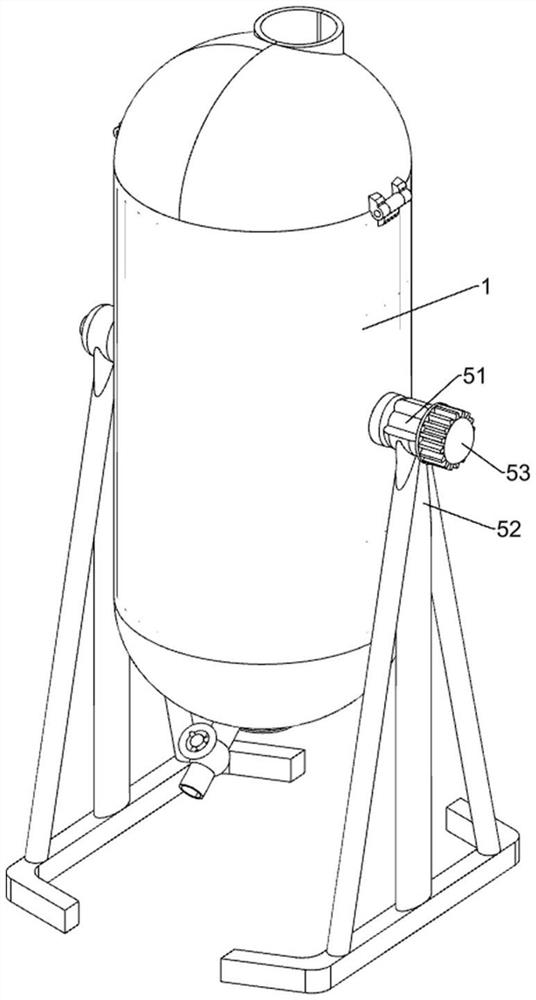

[0037] The rotating mechanism 5 includes a fixed rod 51, a support frame 52 and a first motor 53, see ...

Embodiment 2

[0041] On the basis of Embodiment 1, it also includes a cleaning mechanism 7, and the cleaning mechanism 7 includes a sliding frame 71, an annular rack 72, a brush 73, a protective shell 74, a third motor 75, a first gear box 76, a first gear box 76, a A full gear 77, a second full gear 78 and a threaded rod 79, see figure 2 , Image 6 , Figure 7 and Figure 8 As shown, a sliding frame 71 is slidably connected to the upper middle of the fixed frame 63, an annular rack 72 is rotatably connected to the outer middle of the sliding frame 71, and a brush 73 is connected to the outer side of the annular rack 72 at intervals. All the pulp residues remaining on the inner wall of the brewing barrel 1 can be brushed off. The brushes 73 are all in contact with the inner wall of the centrifugal rotating barrel 62. The inner front of the sliding frame 71 is connected with a protective shell 74, and the inner bottom of the protective shell 74 is bolted on the right side. A third motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com