Pre-stressed anchor cable capable of preventing seepage through mold bags

A prestressed anchor cable and mold bag technology, which is applied in construction, excavation, and foundation structure engineering, can solve problems such as high cost of plugging construction, poor treatment at the hole opening, and damage to the foundation pit, so as to save follow-up The cost of plugging, easy to widely popularize and use, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

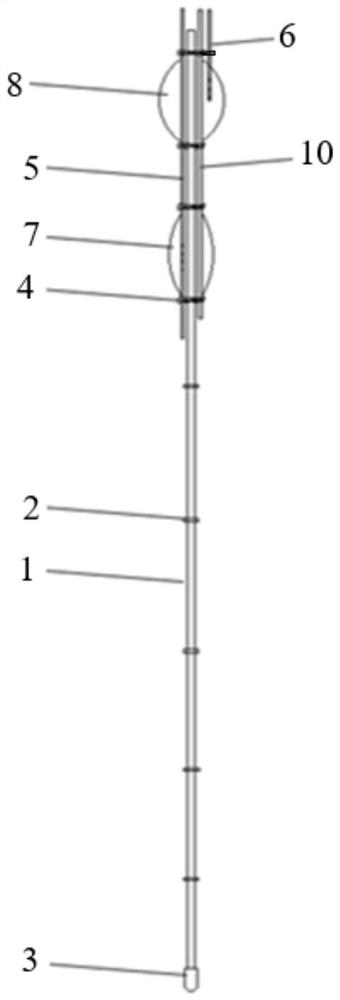

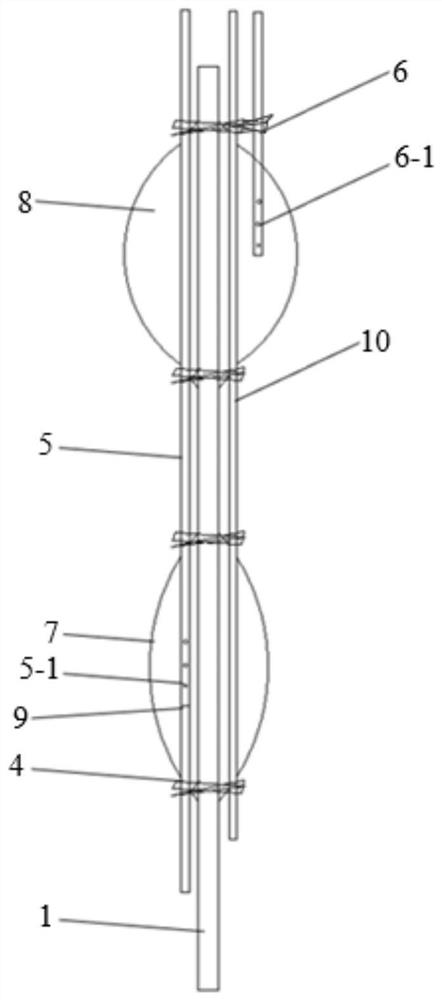

[0019] See Figure 1 to Figure 2 , the embodiment of the present invention provides a prestressed anchor cable using a mold bag for anti-seepage, including an anchor cable main body 1, and the anchor cable main body 1 is formed by several unbonded steel strands fixed by several snap rings 2, The distance between the adjacent snap rings 2 is 2m, so as to ensure the straightness of the steel strand; the lower end of the anchoring section of the anchor cable main body 1 is fixed with a guide cap 3, and the guide cap 3 tightens the end of the steel strand on the lower end of the anchoring section. At the same time, it ensures the smooth installation of the steel strand when it enters the anchor cable hole and enhances the anchoring force of the anchor cable main body 1 .

[0020] A first grouting pipe 5 and a second grouting pipe 6 are bound side by side on the anchor cable main body 1 through steel wires 4 , and the first grouting pipe 5 and the second grouting pipe 6 are integra...

Embodiment 2

[0026] The embodiment of the present invention provides a construction method of a prestressed anchor cable using a mold bag to prevent seepage, which specifically includes the following steps:

[0027] Step 1: Drill the anchor cable hole in the side wall of the foundation pit.

[0028] According to the design requirements, use the measuring instrument to determine the hole position and mark it, and then use the down-the-hole impact drilling machine to drill according to the design requirements. Use a polyethylene tube to check the depth of the hole, and blow the hole with high pressure air to clean the inside of the hole.

[0029] Step 2: Arrange the first grouting pipe, the second grouting pipe, the first anti-seepage mold bag, the second anti-seepage mold bag and the grout pipe on the main body of the anchor cable, and lower the main body of the anchor cable to the anchor cable inside the tunnel.

[0030] Fix the first grouting pipe, the second grouting pipe, the grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com