Operation method for water leakage repair of converter support ring

A converter support ring and operation method technology, which is applied in the direction of manufacturing converters, workpiece edge parts, manufacturing tools, etc., can solve the problems of large internal stress, narrow operator passage space, complicated welding seams, etc., and save materials and manufacturing costs. , to ensure normal operation, good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

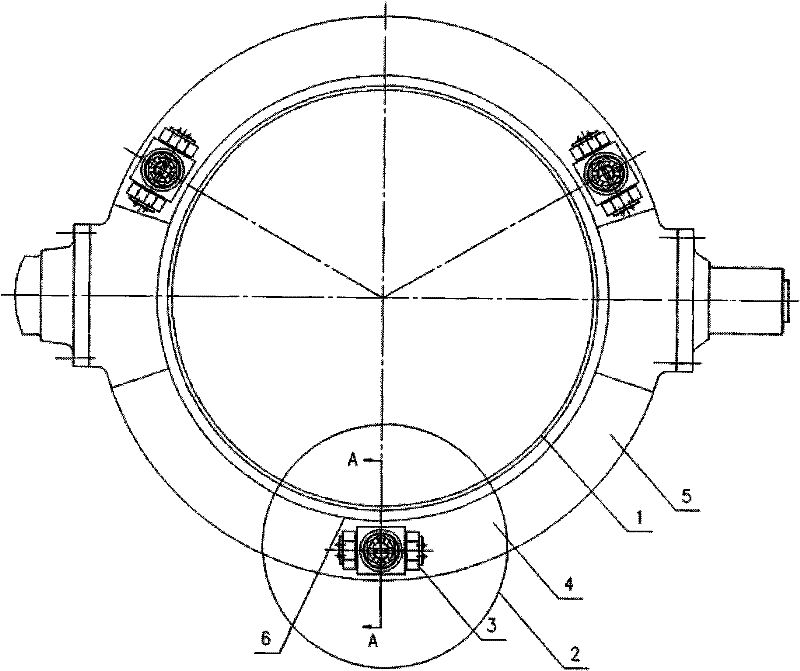

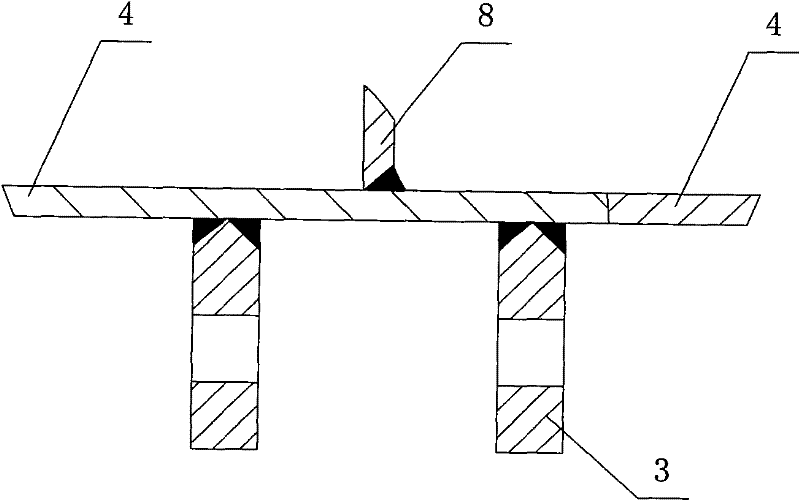

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

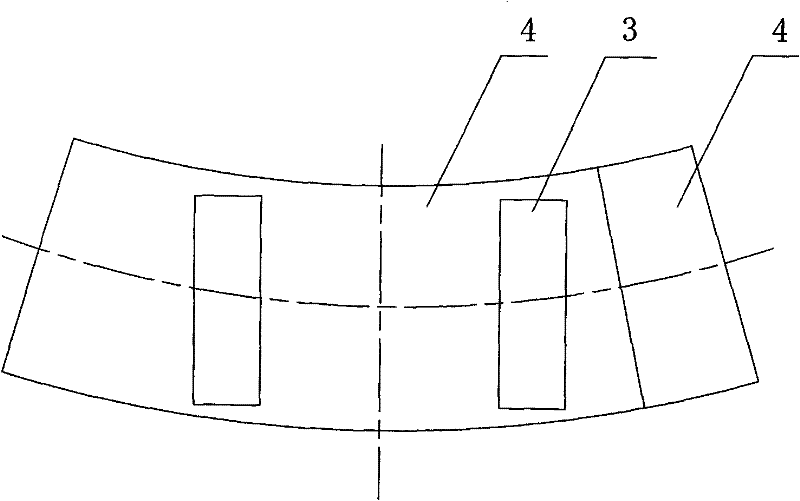

[0025] 1. First, remove the components of the upper cover plate 4 of the support ring at the repair part 2 of the support ring. The upper cover plate 4 must be able to stand on the surface of the steel plate for grinding and flaw detection. Determine the specific defect location and size. Then proceed to the next step of program repair.

[0026] 2. Open the skylight of the furnace shell 1 at the repair part 2 of the supporting ring, the width is 400-500mm (the specific size is determined after the refractory material is disassembled in the steel factory), and the length is 300mm longer than the length of the defect. (Three holes can be opened according to the determined defect length of about 3000mm, and 100mm connection is left between each hole to prevent deformation. In order to ensure the quality of welding, the connection should avoid the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com