Carbon fiber composite template

A technology of carbon fiber and carbon fiber cloth, which is applied in the field of construction engineering to achieve the effects of reducing on-site workload, improving load-bearing capacity, and simple processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

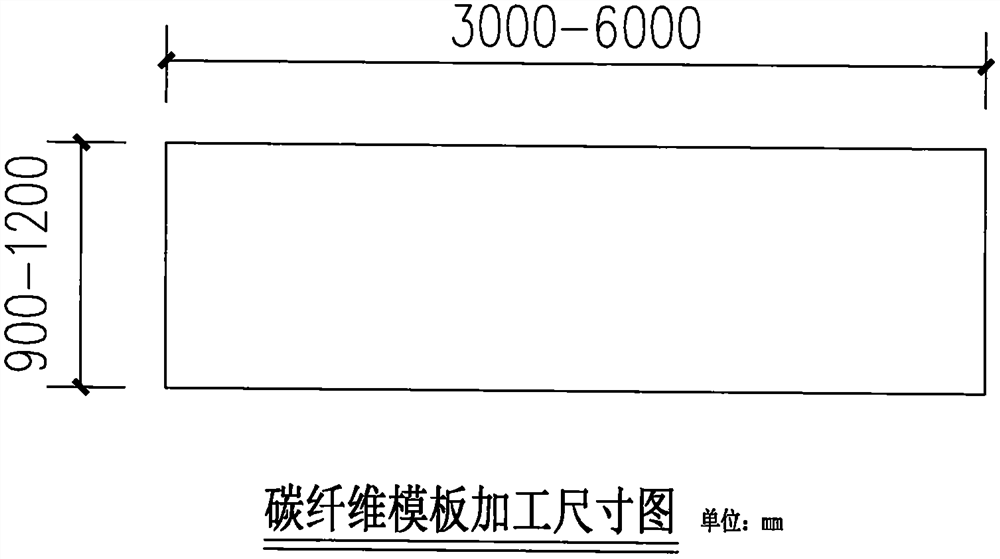

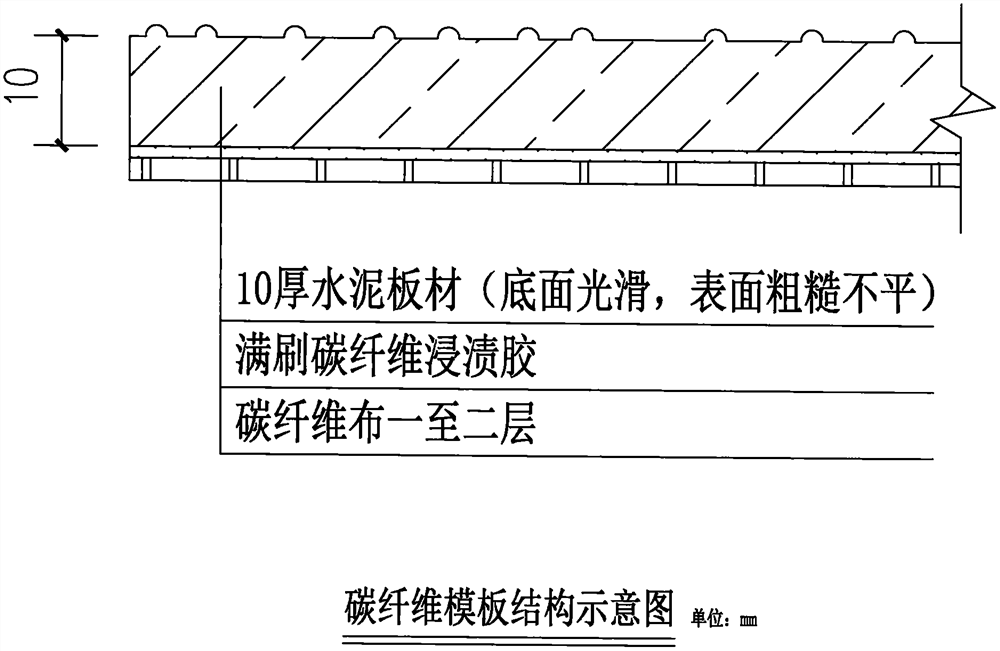

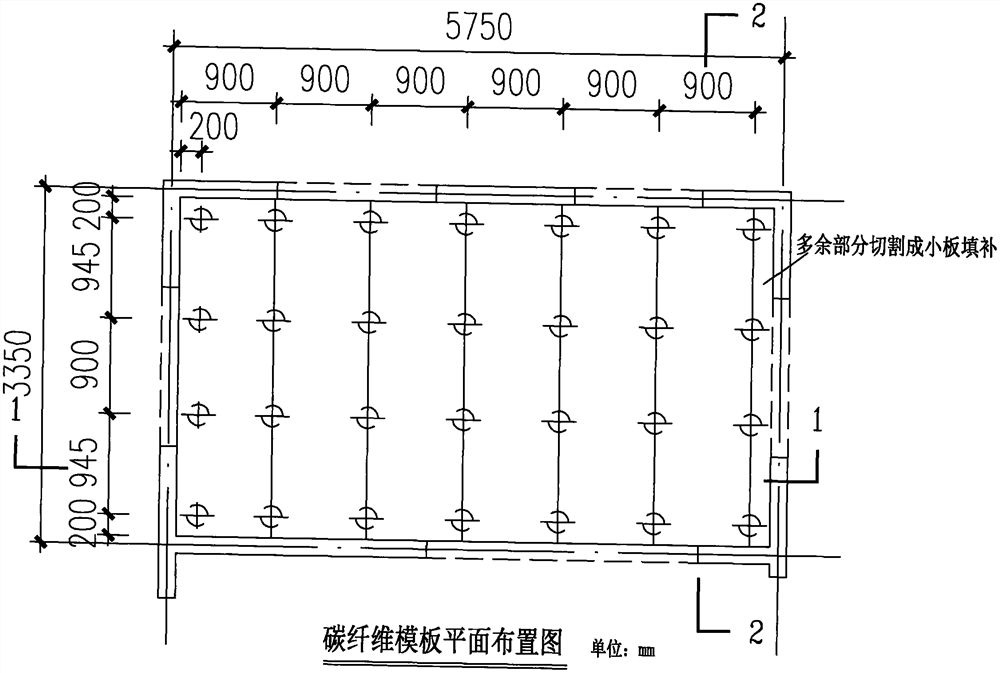

[0020] 1. The implementation of the carbon fiber composite formwork starts from the processing of the existing factory. There are many various cement board processing plants all over the country, and all of them can be produced. It is only slightly adjusted in the process. Generally, the cement board is smooth on both sides. The cement board of the present invention It is smooth on one side and rough or striped on the other side, which is convenient for combining with cast-in-place concrete. The processing thickness is 5 to 10mm, and the thickness can be increased as needed. The length and width of the processing can be determined according to the requirements of on-site use, transportation conditions and the capacity of the processing plant. Generally, the width is 900mm to 1200mm, and the length is 3000mm to 6000mm.

[0021] 2. The construction unit purchases standard products from the manufacturer according to the requirements of the construction building, or orders the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com