Dust-free room partition wall and construction process thereof

A construction process and partition wall technology, which is applied in the field of sheet metal manufacturing, can solve the problems of long construction time, large size and small space, and achieve the effects of good insulation performance, long service life and no maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

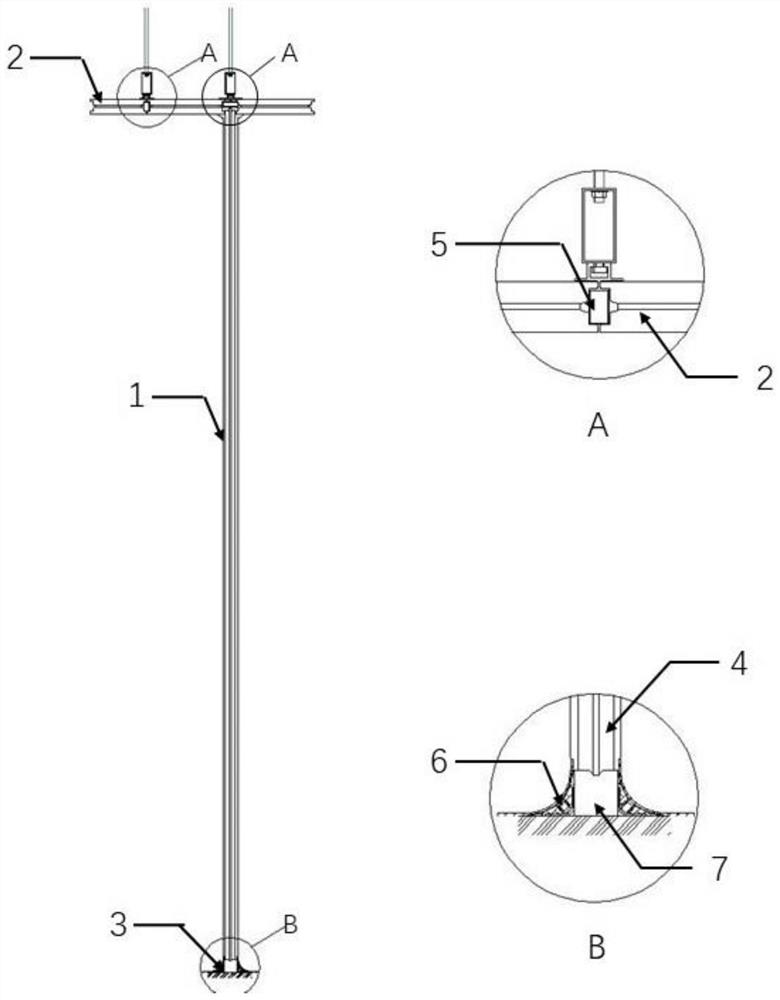

[0072] This embodiment provides a clean room partition wall. The clean room partition wall includes a partition wall 1, a top plate 2 and a bottom plate 3. The partition wall 1 includes partition plates 4 connected in sequence, and the partition plate 4 includes FRP materials, such as figure 1 and figure 2 shown.

[0073] The upper end surface of the partition wall 1 is arc-shaped. A keel 5 is arranged on the top plate 2 for connecting the top plate 2 and the partition wall 1 , and a fixing screw is arranged on the keel 5 for fixing the keel 5 and the partition wall 1 .

[0074] The lower end surface of the partition wall 1 is provided with a ground rail 7 for fixedly connecting the partition plate 4 and the bottom plate 3 , and the connection includes a sliding connection. A patch base 6 is arranged at the included angle between the ground rail 7 and the bottom plate 3 , and arc patches are arranged on the patch base 6 .

[0075] The partition wall 1 includes a partition...

Embodiment 2

[0095] This embodiment provides a clean room partition wall. The clean room partition wall includes a partition wall 1, a top plate 2 and a bottom plate 3. The partition wall 1 includes partition plates 4 connected in sequence, and the partition plate 4 includes FRP materials, such as figure 1 and figure 2 shown.

[0096] The upper end surface of the partition wall 1 is arc-shaped. A keel 5 is arranged on the top plate 2 for connecting the top plate 2 and the partition wall 1 , and a fixing screw is arranged on the keel 5 for fixing the keel 5 and the partition wall 1 .

[0097] The lower end surface of the partition wall 1 is provided with a ground rail 7 for fixedly connecting the partition plate 4 and the bottom plate 3 , and the connection includes a sliding connection. A patch base 6 is arranged at the included angle between the ground rail 7 and the bottom plate 3 , and arc patches are arranged on the patch base 6 .

[0098] The partition wall 1 includes a partition...

Embodiment 3

[0118] This embodiment provides a clean room partition wall. The clean room partition wall includes a partition wall 1, a top plate 2 and a bottom plate 3. The partition wall 1 includes partition plates 4 connected in sequence, and the partition plate 4 includes FRP materials, such as figure 1 and figure 2 shown.

[0119] The upper end surface of the partition wall 1 is arc-shaped. A keel 5 is arranged on the top plate 2 for connecting the top plate 2 and the partition wall 1 , and a fixing screw is arranged on the keel 5 for fixing the keel 5 and the partition wall 1 .

[0120] The lower end surface of the partition wall 1 is provided with a ground rail 7 for fixedly connecting the partition plate 4 and the bottom plate 3 , and the connection includes a sliding connection. A patch base 6 is arranged at the included angle between the ground rail 7 and the bottom plate 3 , and arc patches are arranged on the patch base 6 .

[0121] The partition wall 1 includes a partition p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com