Imitated natural stone vitrified tile using industrial waste as raw material and preparation method of imitated natural stone vitrified tile

A technology imitating natural stone and industrial waste, which is applied in the field of vitrified bricks and its preparation, can solve the problems of difficult raw material treatment of industrial waste, high crushing cost, low water absorption, etc., achieve rich surface colors, expand application fields, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

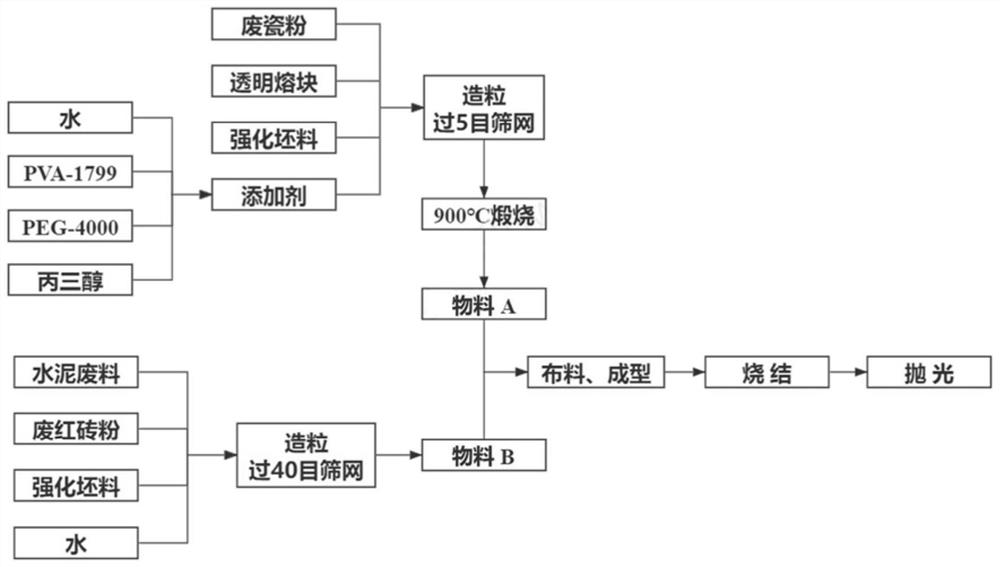

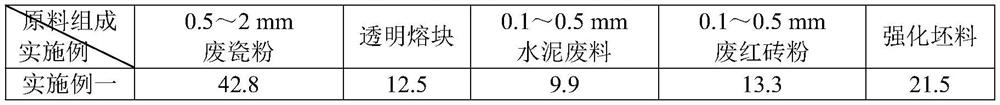

[0026] The embodiment of the present invention is a natural stone imitation vitrified brick using industrial waste as raw material. The raw material is composed of: 40-55 wt% of waste porcelain powder with a particle size of 0.5-2mm, 12-18 wt% of transparent frit, and a particle size of 0.1 6-10 wt% of 0.5 mm cement waste, 10-15 wt % of waste red brick powder with a particle size of 0.1-0.5 mm, and 14-22 wt % of reinforced blank. The raw material composition of each embodiment is as shown in table 1.

[0027] Table 1 Raw material composition (wt %) of each embodiment of the present invention

[0028]

[0029]

[0030] The waste porcelain powder is broken from daily-use ceramic waste porcelain with a sintering temperature of 1250-1320°C and a surface glaze layer thickness of 0.5-2.0mm. Waste red brick powder is broken into sintered building clay bricks with a firing temperature of 850-950°C. Cement waste is broken from cement mortar used for building exterior walls and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com