Substitution trolley of rear matched wheel for station crossing of whole tunnel boring machine

A technology of tunnel boring machine and post-support, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve problems such as time-consuming and damage to shifting devices, and achieve the effects of shortening the construction period, easy disassembly and assembly, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

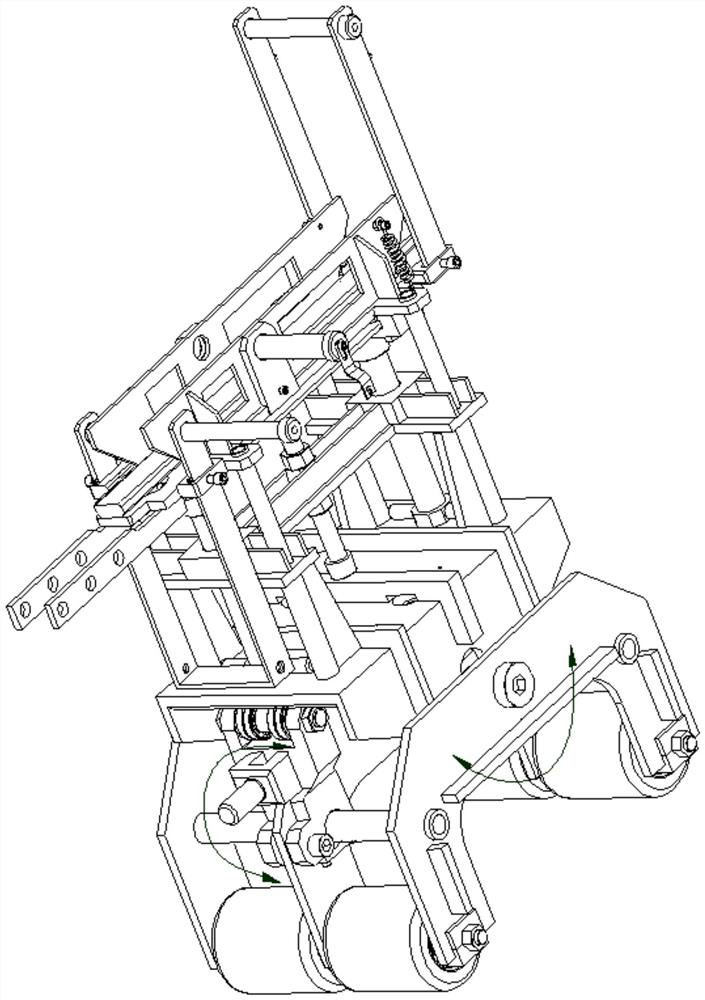

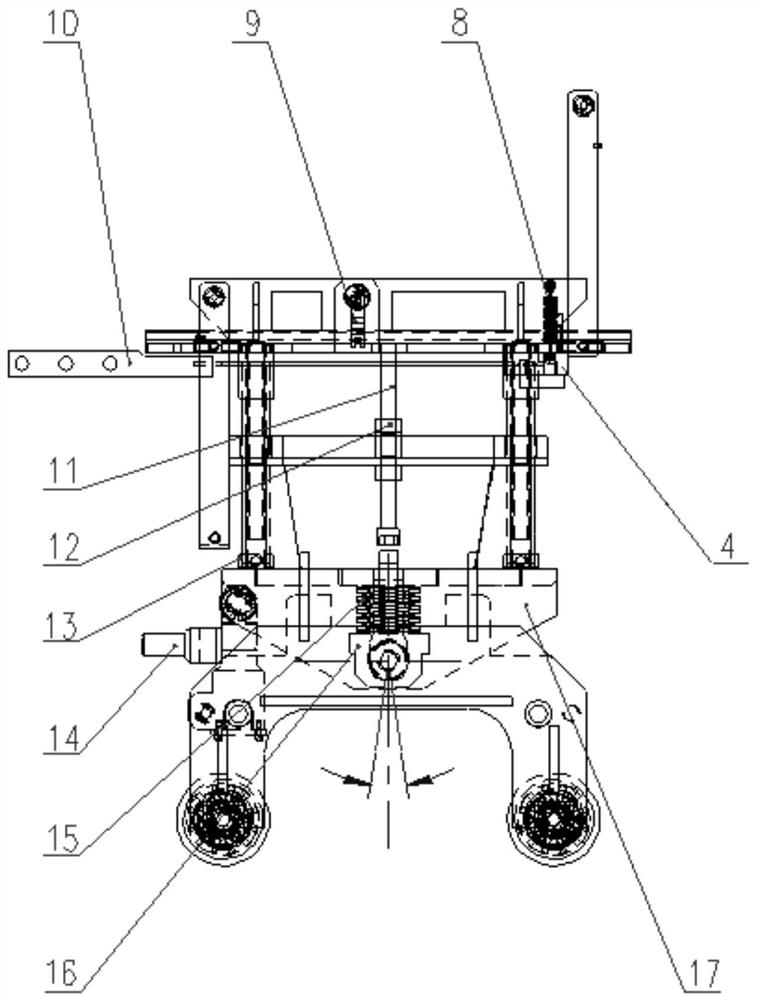

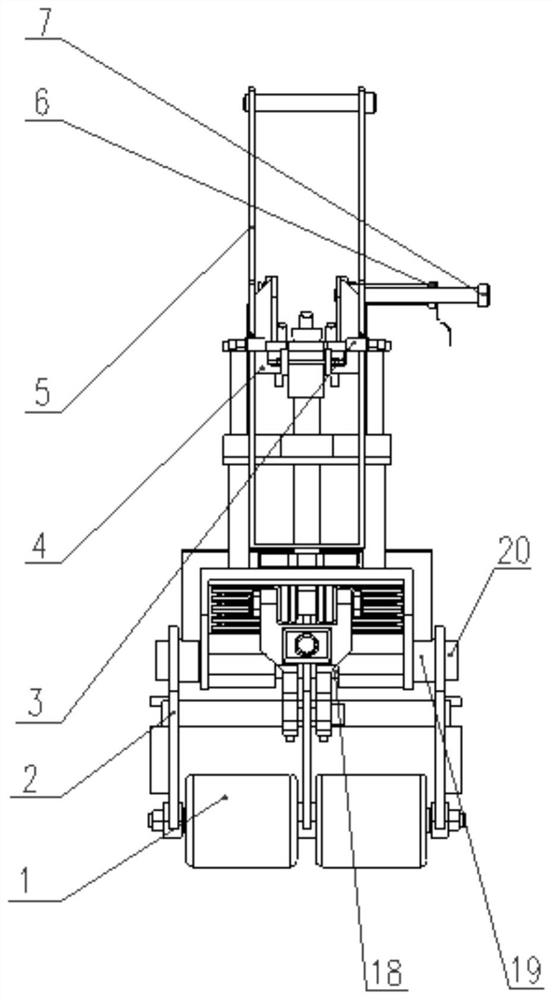

[0050] The following examples are combined with the attached Figure 1-8 , the technical solutions of the present invention are further described in detail.

[0051] as attached Figure 1-3 As shown in the figure, the present embodiment provides an alternative trolley for the rear supporting wheels of the complete tunnel boring machine passing through the station. Wheel train frame 2 and 4 nylon wheels 1.

[0052] as attached Figure 4 As shown, the nylon wheel set 1 includes an axle 21, a bearing mounting frame 22, a steel sleeve 23, a grooved nylon wheel 24, an outer bearing cover 25, a rubber sealing ring 26, an inner bearing cylinder 27, a gasket 28, and a rolling bearing 29 and load-bearing cylinder 30.

[0053] The steel sleeve 23 in the nylon wheel set 1 is its bracket, one end of which is provided with a small oil injection hole, and the ring welding block in the middle acts as a reinforcing rib; near the two outer ends, a row of uniformly distributed circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com