Roasting furnace burner channel refractory ramming material construction method

A construction method and roasting furnace technology, applied in the direction of lining repair, etc., can solve the problems of complex channel shape, increased construction cost, low construction efficiency, etc., achieve the effect of simple and convenient control method, reduce construction cost, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The construction process of the refractory ramming material construction method for the burner burner channel of the present invention:

[0037] Lightweight castables and light-weight refractory bricks in burner channel are completed → installation of centerline control device → installation of the first solid wood mold → ramming of the refractory ramming material around the first mold → removal of the first mold of the mold → installation of the second mold of the solid wood mold → ramming the refractory ramming material around the second mold → removing the second mold → installing the third solid wood mold → ramming the refractory ramming material around the third mold → removing the third mold → installing the fourth solid wood mold → ramming the fourth mold Peripheral refractory ramming material → remove the 4th mold → install 3 solid wood 5th molds → ramming the surrounding refractory ramming material of the 5th mold → remove the 5th mold → remove the centerline co...

PUM

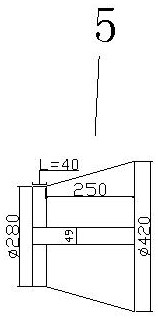

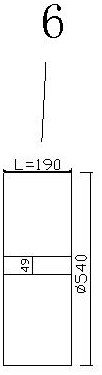

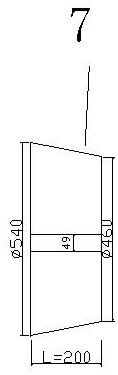

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com