Mesoporous carbon material high in specific surface area and rich in oxygen surface functional groups, and preparation method thereof

A technology with surface functional groups and high specific surface area, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve unfavorable application and promotion of porous carbon materials, loss of O and H, and increased difficulty and other problems, to achieve the effect of cheap raw material cost, good formability, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

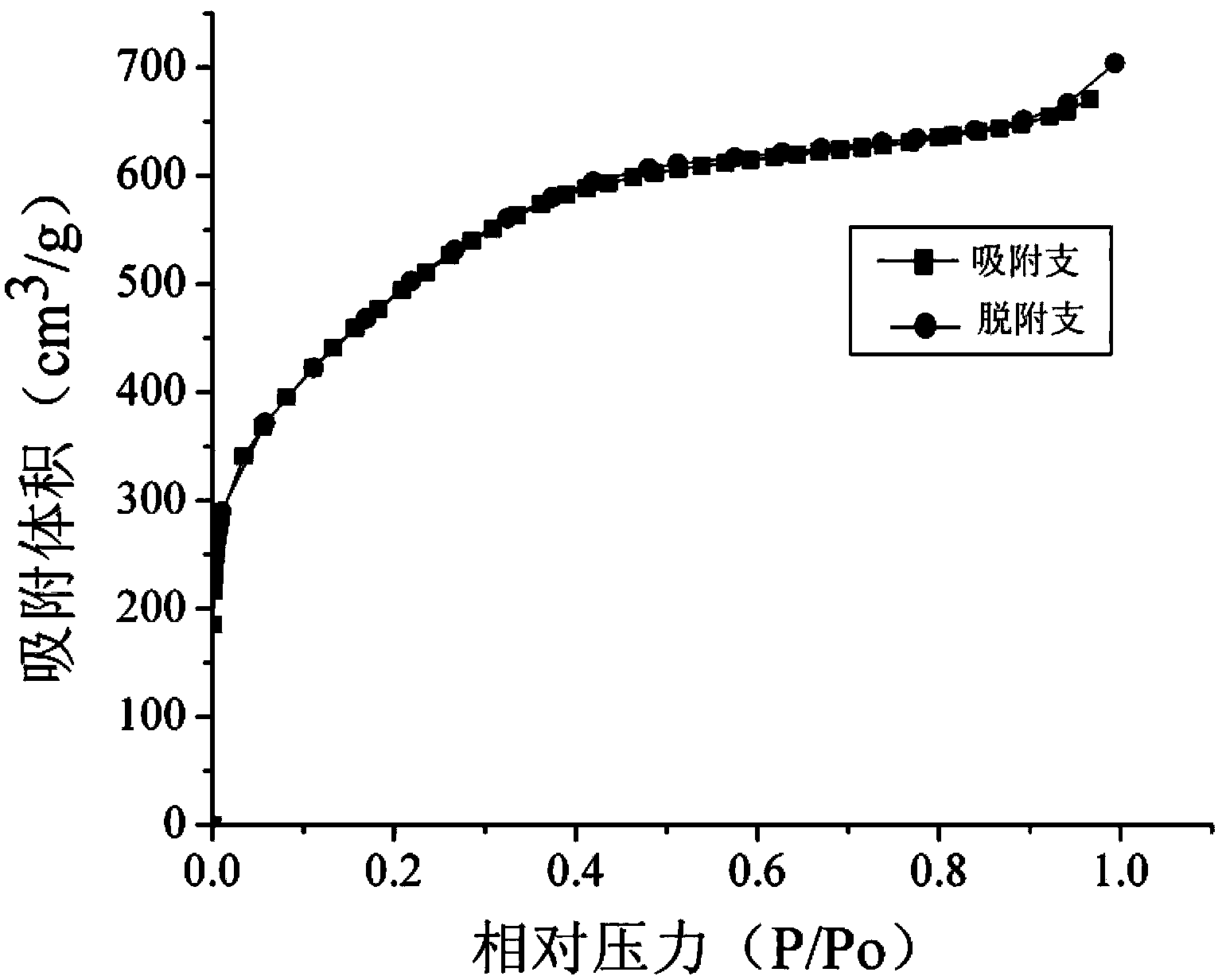

Embodiment 1

[0033] A high specific surface micro-mesoporous carbon material rich in oxygen surface functional groups of the present invention, the specific surface area of the micro-mesoporous carbon material is 1364m 2 / g, the average pore diameter is 3.2nm, and the pore capacity is 1.089cc / g. The micro-mesoporous carbon material is modified with various groups including -COOH, -C-OH, -C=O, etc. The mole fractions of C, O, and H contained in the micro-mesoporous carbon material of this embodiment are respectively:

[0034] C: 83.3mol.%

[0035] O: 10.9mol.%

[0036] H: 5.8 mol.%.

[0037] The above-mentioned micro-mesoporous carbon material in this embodiment is mainly prepared through the following steps:

[0038] (1) Preparation of porous carbon precursor: After cross-linking the polysiloxane precursor (the polysiloxane used in each example is a silicone resin containing Si-OH groups) at 250 ° C for 4 h, the The cross-linked product is broken to 150 μm ~ 250 μm; the broken cross-...

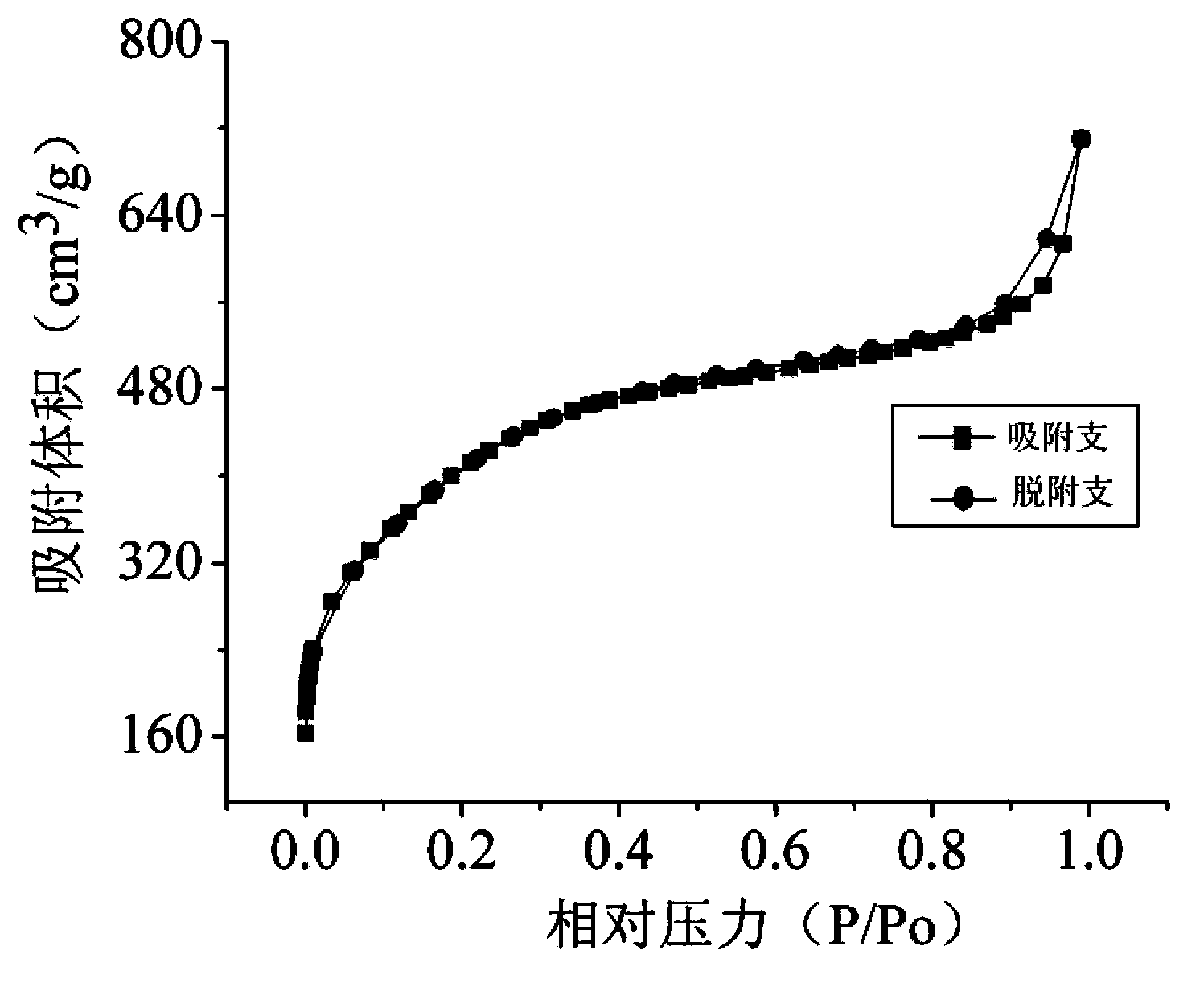

Embodiment 2

[0046] A high specific surface micro-mesoporous carbon material rich in oxygen surface functional groups of the present invention, the specific surface area of the micro-mesoporous carbon material is 1152m 2 / g, the average pore diameter is 3.8nm, and the pore capacity is 1.098cc / g. The micro-mesoporous carbon material is modified with various groups including -COOH, -C-OH, and -C=O. The mole fractions of C, O, and H contained in the micro-mesoporous carbon material of this embodiment are respectively:

[0047] C: 81.4mol.%

[0048] O: 11.6mol.%

[0049] H: 7.0 mol.%.

[0050] The above-mentioned micro-mesoporous carbon material in this embodiment is mainly prepared through the following steps:

[0051] (1) Preparation of porous carbon precursor: After cross-linking the polysiloxane precursor at 250°C for 4 hours, the cross-linked product was crushed to 150 μm to 250 μm; the crushed cross-linked product particles were placed in a cracking furnace for Pyrolysis (protected...

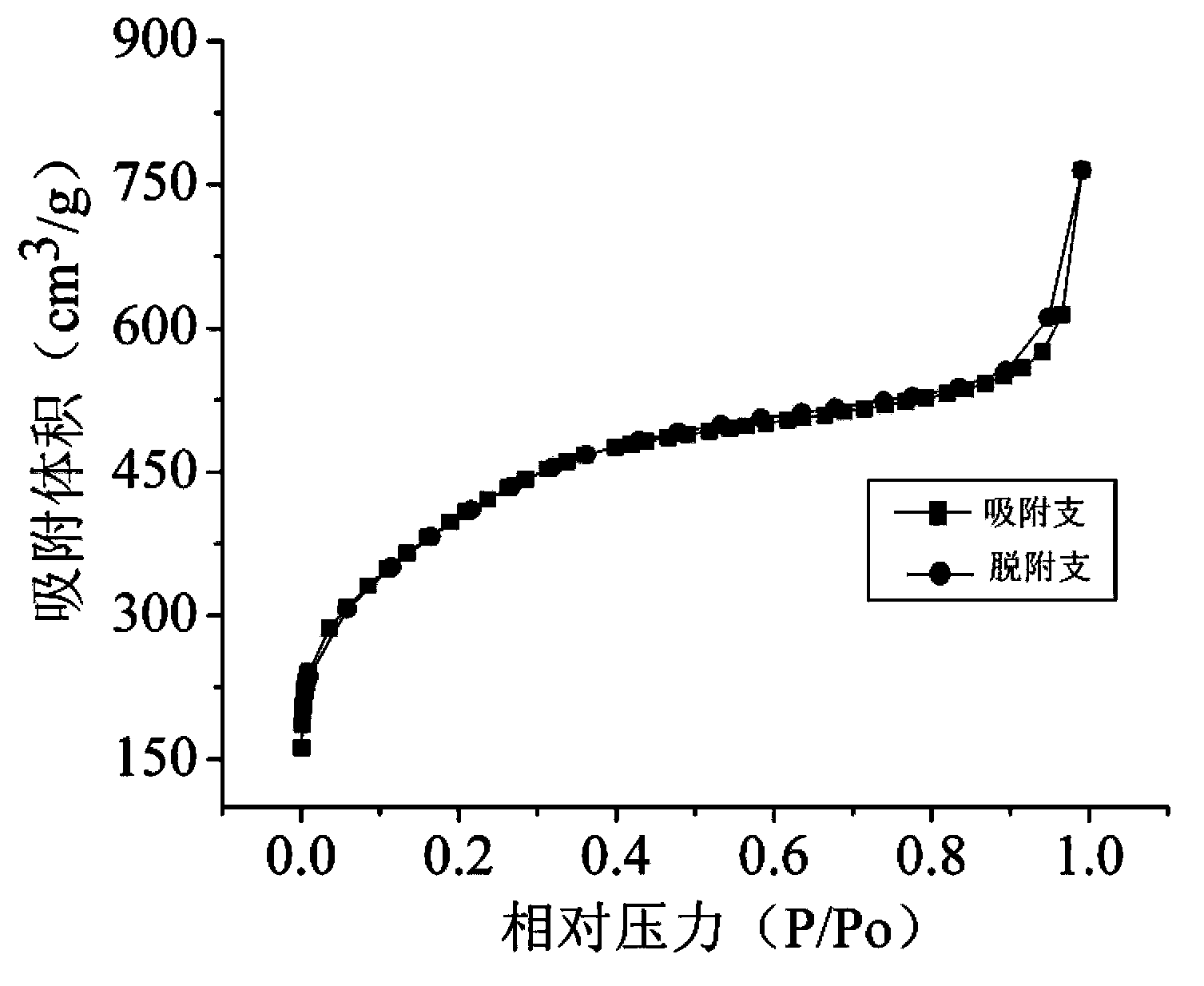

Embodiment 3

[0058] A high specific surface micro-mesoporous carbon material rich in oxygen surface functional groups of the present invention, the specific surface area of the micro-mesoporous carbon material is 1269m 3 / g, the average pore diameter is 3.7nm, and the pore capacity is 1.183cc / g. The micro-mesoporous carbon material is modified with various groups including -COOH, -C-OH, and -C=O. The mole fractions of C, O, and H contained in the micro-mesoporous carbon material of this embodiment are respectively:

[0059] C: 83.7mol.%

[0060] O: 11.5mol.%

[0061] H: 4.8 mol.%.

[0062] The above-mentioned micro-mesoporous carbon material in this embodiment is mainly prepared through the following steps:

[0063] (1) Preparation of porous carbon precursor: After cross-linking the polysiloxane precursor at 250°C for 4 hours, the cross-linked product was crushed to 150 μm to 250 μm; the crushed cross-linked product particles were placed in a cracking furnace for Cracking (protected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com