A kind of separation method of ethylene ethane

A separation method, ethylene technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, adsorption purification/separation, etc., can solve the problems of unfavorable industrial applications, easy deactivation of materials, low adsorption capacity, etc., and achieve precise pore size The effects of regulation, easy availability of raw materials, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1mmol Ni(BF 4 ) 2 , 1mmol (NH 4 ) 2 GeF 6 and 10mmol of pyrazine were placed in a strain bottle, 3ml of water and 1ml of methanol were added, and stirred at room temperature for 48h. After suction filtration, the obtained slurry was activated for 12h under vacuum at 140°C to obtain GeFSIX-3-Ni material.

[0045] Fill the obtained GeFSIX-3-Ni material into a 5cm adsorption column, and pass 0.2Mpa ethylene: ethane (93.7:6.3) mixed gas into the adsorption column at 25°C at 1mL / min, and high purity can be obtained in the outflow gas Ethane (greater than 99.99%) gas, when ethylene breaks through, stops adsorption. The adsorption column adopts vacuum desorption at 100°C to obtain ethylene (purity greater than 98%), and the adsorption column can be recycled.

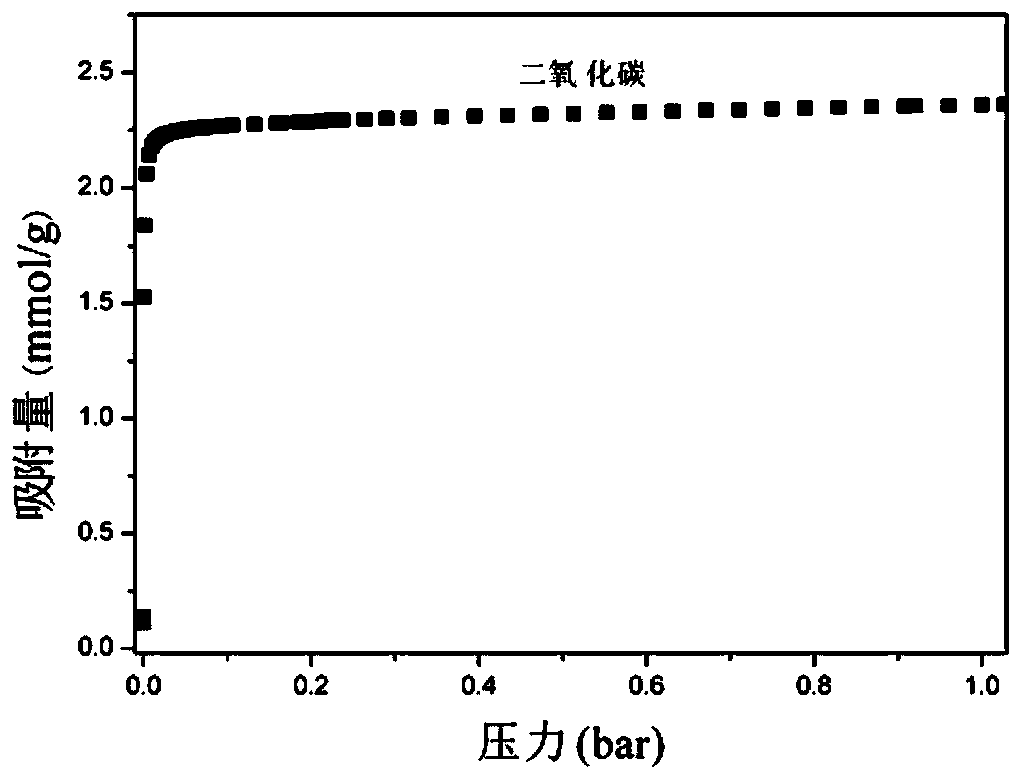

[0046] figure 1 CO for GeFSIX-3-Ni material at 298K and 1atm 2 The adsorption isotherm;

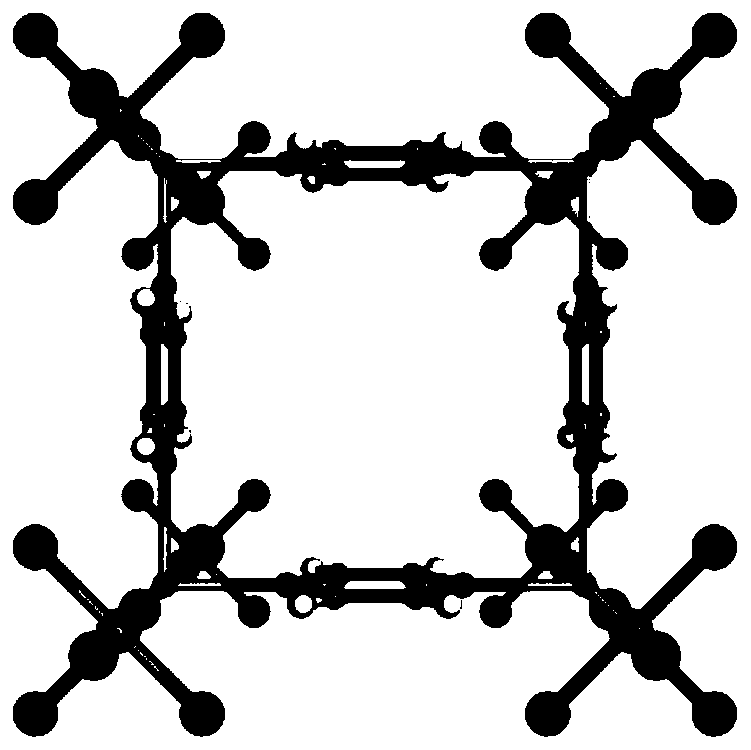

[0047] figure 2 is the crystal unit structure diagram of GeFSIX-3-Ni material, where Inorganic anion GeF 6 2- , i...

Embodiment 2

[0054] 1mmol Ni(NO 3 ) 2 , 1mmol (NH 4 ) 2 GeF 6 and 3 mmol of pyrazine were placed in a ball mill jar, and after ball milling at 800 r / min for 15 min, the resulting material was washed with 10 ml of methanol, then suction-filtered, and vacuum activated at 100°C for 12 hours to obtain GeFSIX-3-Ni material.

[0055] The obtained GeFSIX-3-Ni material was packed into a 10cm adsorption column, and 0.5Mpa ethylene: ethane (50:50) mixed gas was passed into the adsorption column at 0.5mL / min at 25°C, and high Purity ethane (greater than 99.99%) gas, when ethylene breaks through, the adsorption stops. The adsorption column adopts vacuum desorption at 100°C to obtain ethylene (purity greater than 95%), and the adsorption column can be recycled.

[0056] The breakthrough curve of GeFSIX-3-Ni material for ethylene / ethane (50 / 50) gas mixture at 298K and 1atm is as follows Figure 4 shown.

Embodiment 3

[0058] 1mmol Co(NO 3 ) 2 , 1mmol (NH 4 ) 2 TiF 6 and 12.5 mmol of pyrazine were placed in a strain bottle, 2 ml of methanol and 1 ml of water were added, and stirred at room temperature for 48 h. After suction filtration, the obtained slurry was vacuum activated at 140°C for 24 h to obtain TIFSIX-3-Co material.

[0059] The obtained TIFSIX-3-Co material was filled into a 15cm adsorption column, and a 0.2Mpa ethylene: ethane: methane (49:49:2) gas mixture was passed into the adsorption column at 30°C at 2mL / min. When transparent, stop adsorption. The adsorption column adopts vacuum desorption at 130°C to obtain ethylene (purity greater than 90%), and the adsorption column can be recycled.

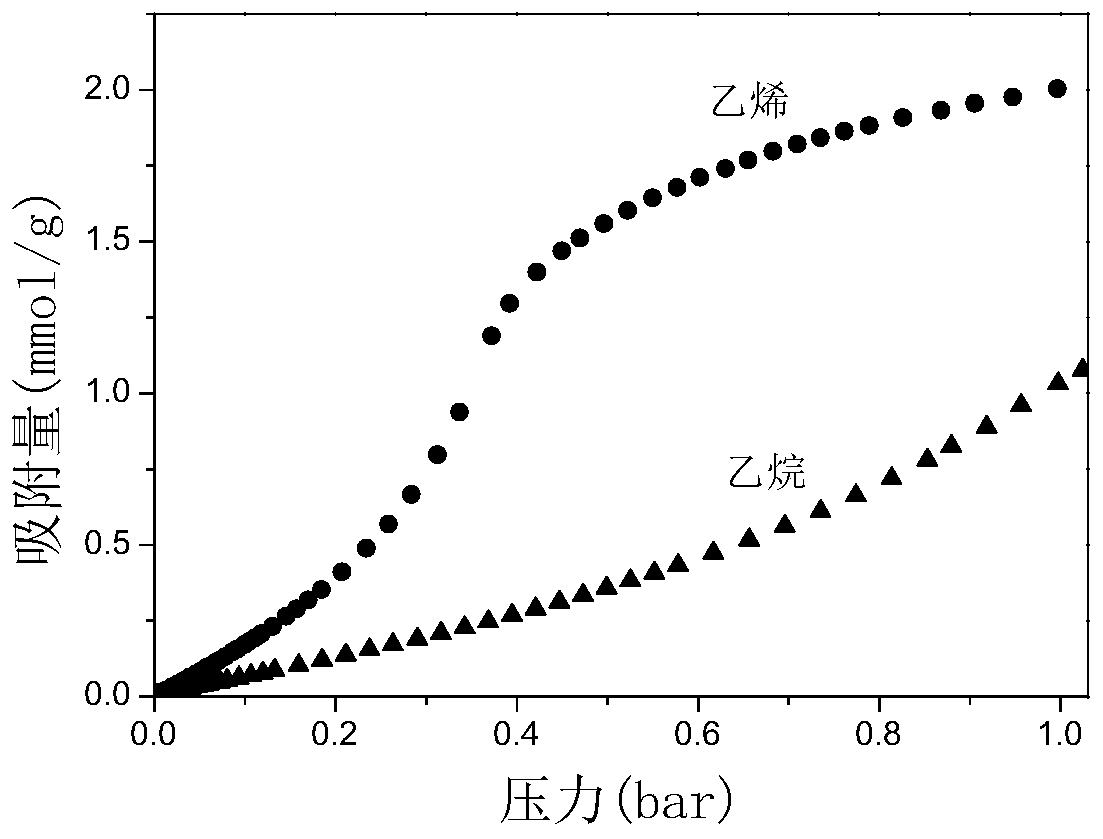

[0060] The adsorption isotherms of TIFSIX-3-Co material for ethylene and ethane at 298K are as follows: Figure 5 shown;

[0061] The thermogravimetric curve of TIFSIX-3-Co material is as follows Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com