Circuit board defect testing method

A defect testing and circuit board technology, applied in the field of circuit board analysis, which can solve problems such as poor soldering quality of solder joints and cracking of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

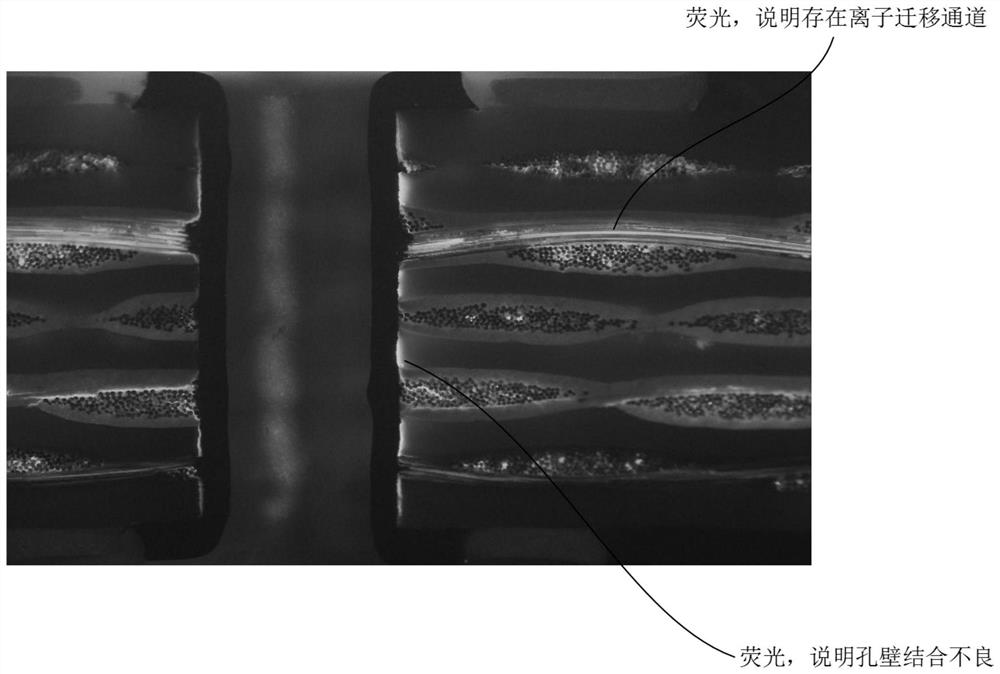

[0057] Immerse the part to be tested on the circuit board in a fluorescent penetrant solution, the fluorescent penetrant solution includes a fluorescent penetrant and an organic solvent, and the mass ratio of the fluorescent penetrant and the organic solvent is 1:20. The fluorescent osmotic solution selected from the new Mita CY-3800 fluorescent osmotic fluid, other fluorescent osmotic fluids can also play a similar role.

[0058] Put the circuit board and the fluorescent osmotic solution together in the vacuum chamber, firstly evacuating the vacuum chamber until the vacuum degree is reduced to below -0.1MPa, keep the vacuum chamber for 3min, return the vacuum chamber to normal pressure, and repeat the vacuuming and Steps to return to normal pressure twice.

[0059] The circuit board was taken out from the fluorescent permeation solution and placed in an oven, the temperature of the oven was 80° C., and the baking time was 1 h, so that there was no residual fluorescent permeat...

Embodiment 2

[0063] Immerse the part to be tested on the circuit board in a fluorescent penetrant solution, the fluorescent penetrant solution includes a fluorescent penetrant and an organic solvent, and the mass ratio of the fluorescent penetrant and the organic solvent is 1:20.

[0064] The circuit board and the fluorescent penetrating solution are placed in a vacuum chamber together, and the vacuum chamber is first evacuated until the vacuum degree is reduced to below -0.1MPa, and kept for 10min.

[0065] The circuit board was taken out from the fluorescent permeation solution and placed in an oven, the temperature of the oven was 80° C., and the baking time was 1 h, so that there was no residual fluorescent permeation solution on the circuit board.

[0066] The circuit board is sampled to obtain the sample to be tested, the sample to be tested is sealed with epoxy resin, and then the sample to be tested is sliced to expose the observation section to be observed, and after slicing, it ...

Embodiment 3

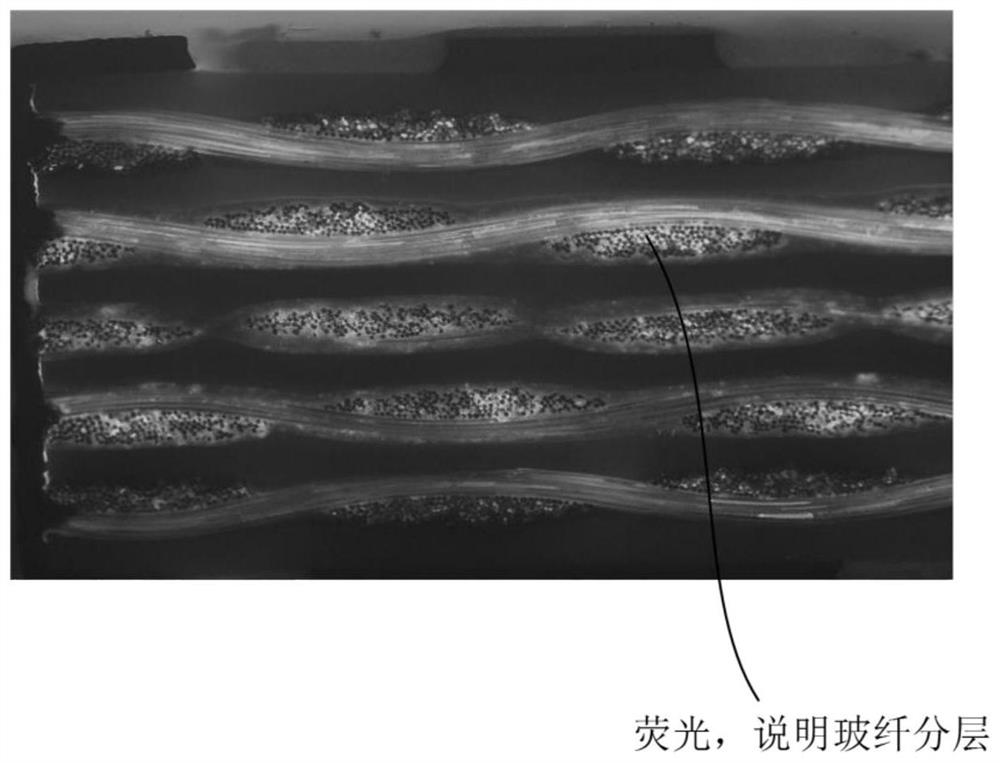

[0069] Immerse the part to be tested on the circuit board in a fluorescent penetrant solution, the fluorescent penetrant solution includes a fluorescent penetrant and an organic solvent, and the mass ratio of the fluorescent penetrant and the organic solvent is 1:30.

[0070] The circuit board and the fluorescent penetrating solution are placed in a vacuum chamber together, and the vacuum chamber is first evacuated until the vacuum degree is reduced to below -0.1MPa, and kept for 10min.

[0071] The circuit board was taken out from the fluorescent permeation solution and placed in an oven, the temperature of the oven was 80° C., and the baking time was 1 h, so that there was no residual fluorescent permeation solution on the circuit board.

[0072] The circuit board is sampled to obtain the sample to be tested, the sample to be tested is sealed with epoxy resin, and then the sample to be tested is sliced to expose the observation section to be observed, and after slicing, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com