Method and device for measuring semiconductor multilayer structure based on second harmonic

A second harmonic, multi-layer structure technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problem of result error, difficult to unify, unable to measure the whole area of the wafer, etc., to achieve the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] specific implementation

[0071] The term "and / or" in this article is only an association relationship to describe the associated objects, indicating that there can be three kinds of relationships, for example, A and / or B, it can mean that A exists alone, A and B exist at the same time, and A and B exist independently B these three cases.

[0072] The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present application. It should be understood by those skilled in the art that the described embodiments are some, but not all, embodiments of the present invention. Based on the embodiments in this application, those skilled in the art can make any suitable modifications or variations to obtain all other embodiments.

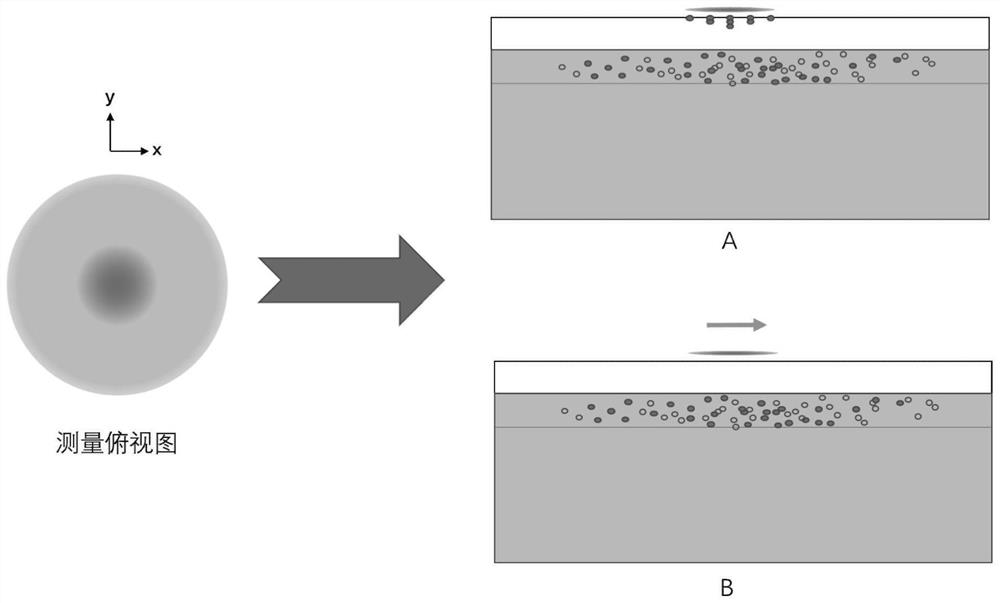

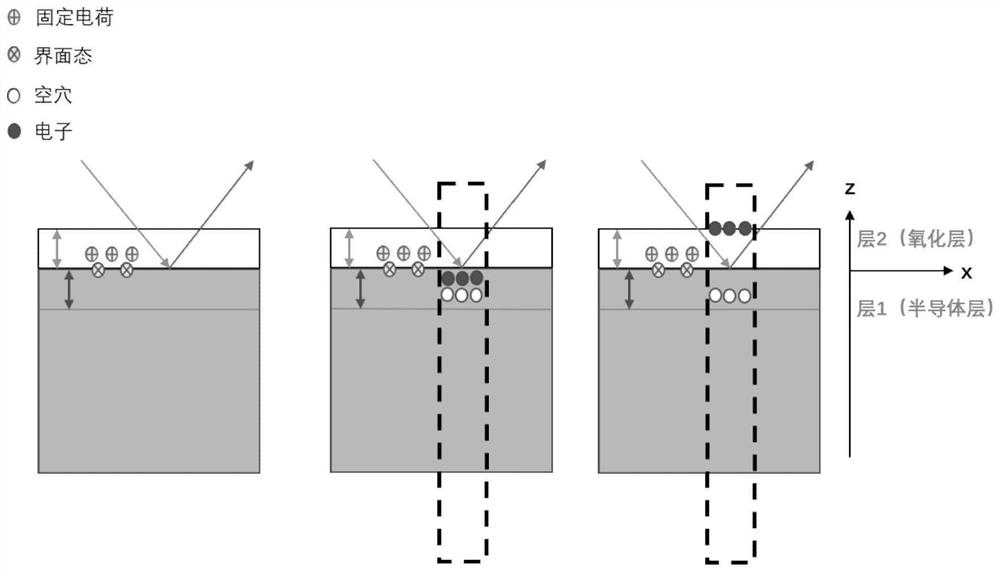

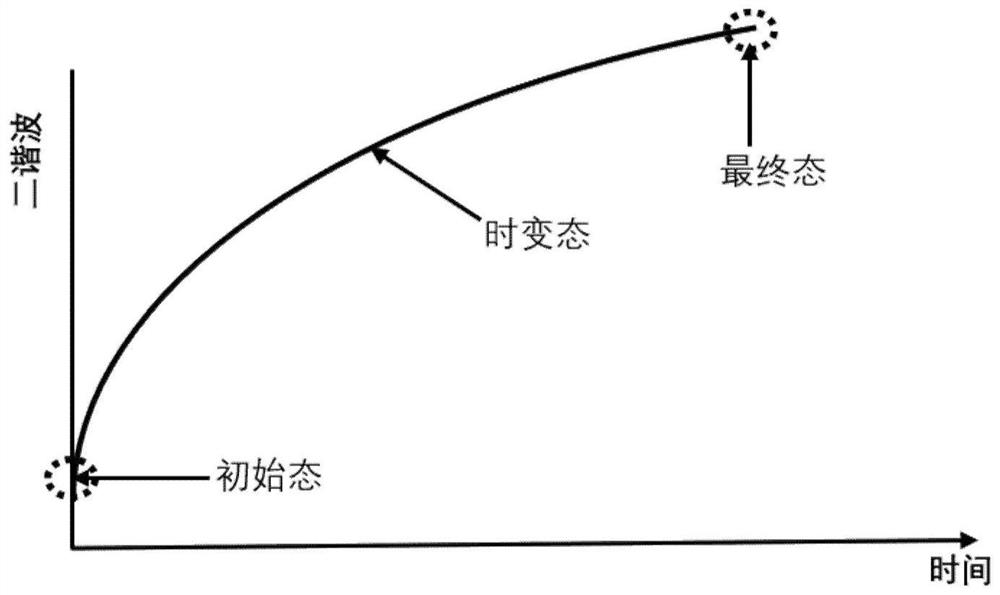

[0073] In a first aspect, an embodiment of the present invention provides a method for measuring a semiconductor multilayer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com