Optical fiber microbubble concentration sensor based on nano-gold film and its sensing method

A concentration sensor and nano-gold technology, which is applied in the field of optical fiber, can solve problems such as limited application range, complicated manufacturing process, and inapplicability to liquid concentration measurement, and achieve the effects of integration, flexible control, and fixed-point measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

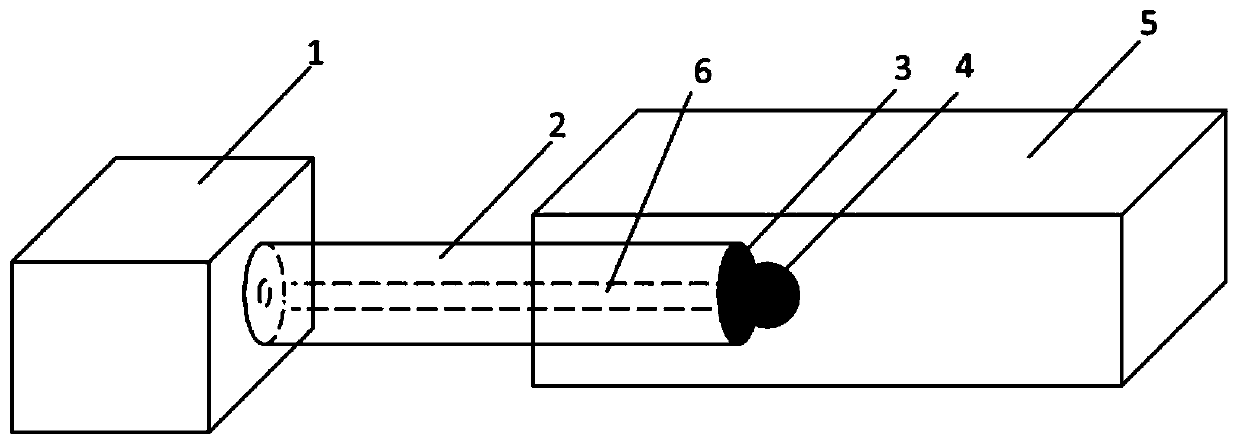

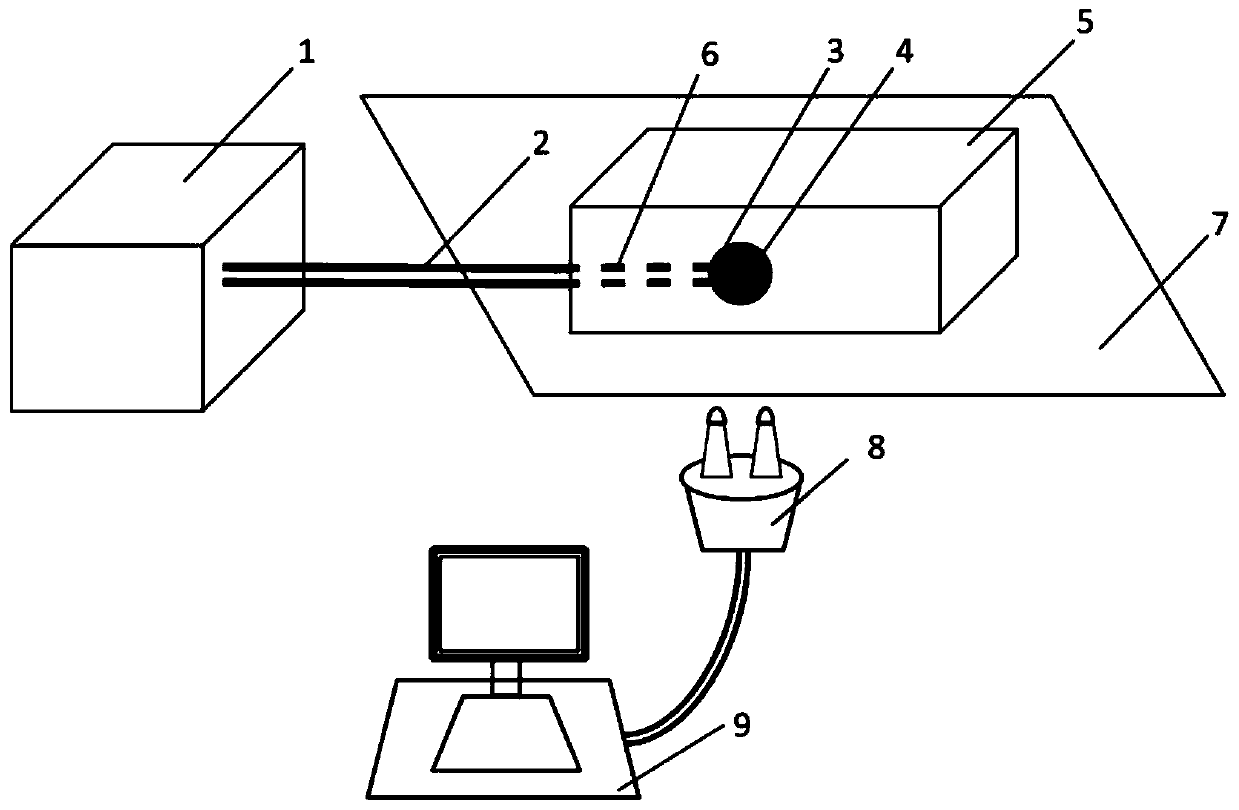

[0022] The sensing device of the optical fiber microbubble concentration sensor based on the photothermal effect of the nano-gold film provided in this embodiment has a structure such as figure 1 As shown, it includes: 1550nm laser 1, 1550 single-mode fiber 2, nano-gold film 3, microbubble 4, microfluidic channel 5, and sensor 6.

[0023] Among them, the ordinary single-mode fiber 2 is a single-mode fiber with a working wavelength of 1550nm. The fiber core is very thin, the core diameter is generally 8 to 10um, and the cladding diameter is 125um. It is a commonly used single-mode fiber in the communication band; nano-gold film 3 has a thickness of 1 nm.

[0024] Splice each section of optical fiber, and the specific operation method of fusion splicing is as follows: first prepare the end face of the optical fiber, strip off the coating layer of the optical fiber, and clean the bare fiber after stripping the coating layer of the optical fiber to prevent pollution, cut the bare ...

Embodiment 2

[0028] This embodiment is further limited on the basis of Embodiment 1. The sensor 6 is a uniform nano-gold film 3 plated at the end face of a cut flat 1550 single-mode optical fiber. According to the photothermal characteristics of the nano-gold film, the Generates microbubbles 4, the microbubble structures used for sensing. Most of the probe-type optical fiber sensors in the prior art adopt the method of micromachining on the end face of the optical fiber. The manufacturing process of these methods is complicated and difficult. Preparation time reduces costs.

Embodiment 3

[0030] This embodiment also provides a method for preparing an optical fiber microbubble concentration sensor based on the photothermal effect of a nano-gold film, which specifically includes the following steps:

[0031] Step 1): cutting one end face of the single-mode optical fiber flat to obtain a flat end face of the optical fiber;

[0032] Step 2): Place the single-mode optical fiber in the gold-spraying instrument, with the flat end facing the gold target vertically and fix it;

[0033] Step 3): By adjusting the parameters of the gold spraying instrument, the coating thickness on the flat end surface of the single-mode optical fiber is controlled, and the operation of plating nano-gold film on the flat end surface of the single-mode optical fiber is completed to obtain a sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com