Air-cooled hydrogen fuel cell system and emission control method

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as inability to warn of abnormal conditions, inability to eliminate the risk of water accumulation in the flow field, and inability to adjust discharge strategies, etc. , to achieve the effect of eliminating the risk of water accumulation, optimizing the control strategy, and preventing the phenomenon of reverse polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

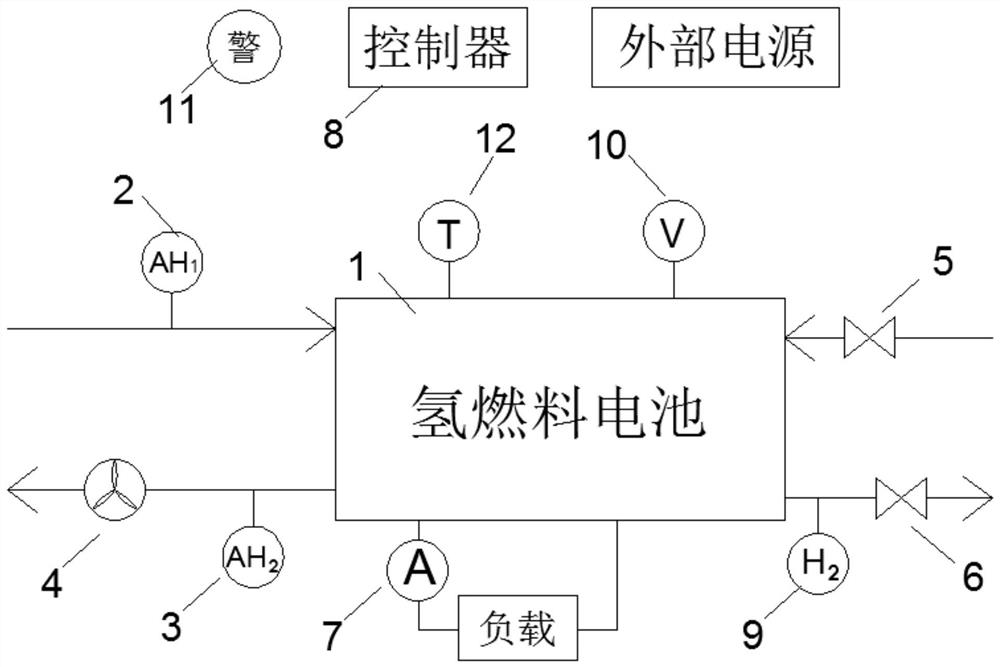

[0043] see attached figure 1 . An air-cooled hydrogen fuel cell system, comprising a hydrogen fuel cell 1, a first humidity sensor 2, a second humidity sensor 3, an exhaust fan 4, an intake solenoid valve 5, an exhaust solenoid valve 6, a current meter 7 and a controller 8 The hydrogen fuel cell 1 generates electricity through the electrochemical reaction between the hydrogen supplied to the anode side of the hydrogen fuel cell 1 and the oxygen in the air at the cathode side of the hydrogen fuel cell 1; the first humidity sensor 2 is used to obtain the information entering the hydrogen fuel cell 1. The absolute humidity of the air on the cathode side; the second humidity sensor 3 is used to obtain the absolute humidity of the air discharged from the cathode side of the hydrogen fuel cell 1; the exhaust fan 4 is used to provide air to flow on the cathode side of the hydrogen fuel cell 1 The power of the gas inlet solenoid valve 5 is used to control the entry of hydrogen into t...

Embodiment 2

[0045] see attached figure 1. An air-cooled hydrogen fuel cell system, comprising a hydrogen fuel cell 1, a first humidity sensor 2, a second humidity sensor 3, an exhaust fan 4, an intake solenoid valve 5, an exhaust solenoid valve 6, a current meter 7 and a controller 8 The hydrogen fuel cell 1 generates electricity through the electrochemical reaction between the hydrogen supplied to the anode side of the hydrogen fuel cell 1 and the oxygen in the air at the cathode side of the hydrogen fuel cell 1; the first humidity sensor 2 is used to obtain the information entering the hydrogen fuel cell 1. The absolute humidity of the air on the cathode side; the second humidity sensor 3 is used to obtain the absolute humidity of the air discharged from the cathode side of the hydrogen fuel cell 1; the exhaust fan 4 is used to provide air to flow on the cathode side of the hydrogen fuel cell 1 The power of the gas inlet solenoid valve 5 is used to control the entry of hydrogen into th...

Embodiment 3

[0051] see attached figure 1 . An air-cooled hydrogen fuel cell system, comprising a hydrogen fuel cell 1, a first humidity sensor 2, a second humidity sensor 3, an exhaust fan 4, an intake solenoid valve 5, an exhaust solenoid valve 6, a current meter 7 and a controller 8 The hydrogen fuel cell 1 generates electricity through the electrochemical reaction between the hydrogen supplied to the anode side of the hydrogen fuel cell 1 and the oxygen in the air at the cathode side of the hydrogen fuel cell 1; the first humidity sensor 2 is used to obtain the information entering the hydrogen fuel cell 1. The absolute humidity of the air on the cathode side; the second humidity sensor 3 is used to obtain the absolute humidity of the air discharged from the cathode side of the hydrogen fuel cell 1; the exhaust fan 4 is used to provide air to flow on the cathode side of the hydrogen fuel cell 1 The power of the gas inlet solenoid valve 5 is used to control the entry of hydrogen into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com