Motorcycle engine right box end face milling tool

An engine and end face milling technology, applied in the field of fixtures, can solve the problems of time consumption, unfavorable flexibility, unfavorable long-term use of devices, etc., to achieve the effect of ensuring stability and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

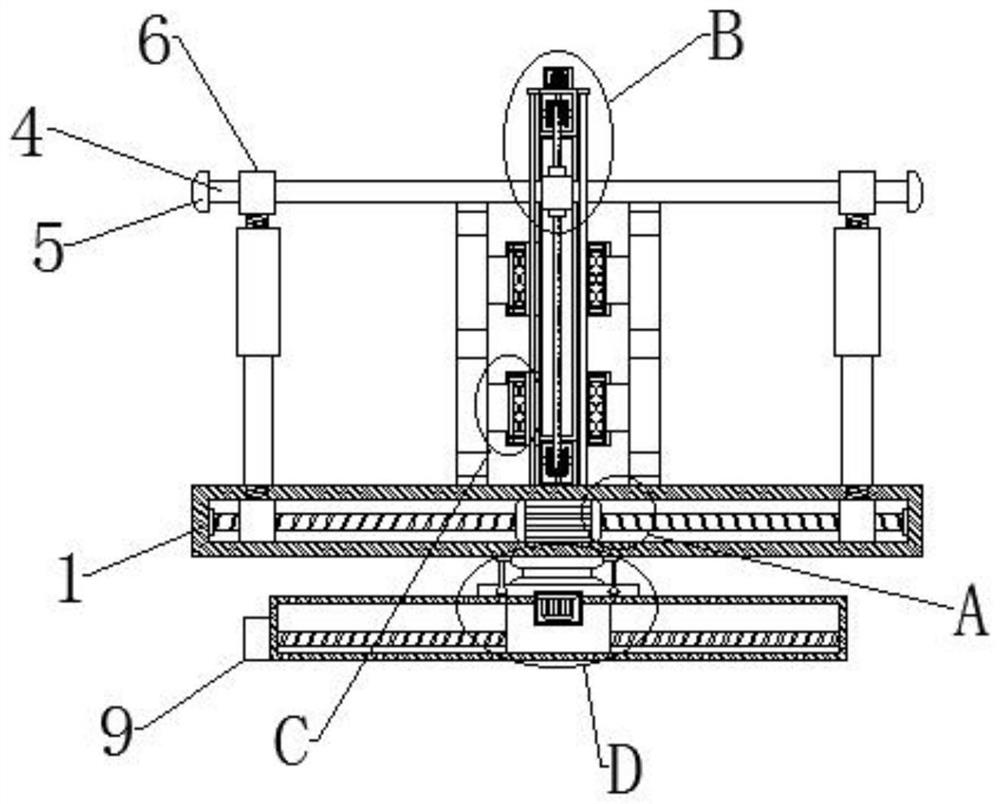

[0035] like Figure 1-8 As shown, it includes a placing platform 1, the inner side of the placing platform 1 is provided with a driving device 2, the top center of the placing platform 1 is provided with a lifting device 3, a limit rod 4 is provided above the left side of the lifting device 3, and the left end of the limit rod 4 is provided The limit block 5 is fixedly connected, the outer wall of the limit rod 4 is provided with a clamping device 6, the middle of the left side of the lifting device 3 is provided with a buffer device 7, the bottom of the placing platform 1 is provided with a rotating device 8, and the left side of the rotating device 8 is provided A transmission device 9 is provided, the clamping device 6 includes a movable sleeve 64, the inner wall of the movable sleeve 64 is movably connected with a movable rod 65, the buffer device 7 includes a mounting shell 71, and the inner wall of the mounting shell 71 is movably connected with a movable plate 72, which ...

Embodiment 2

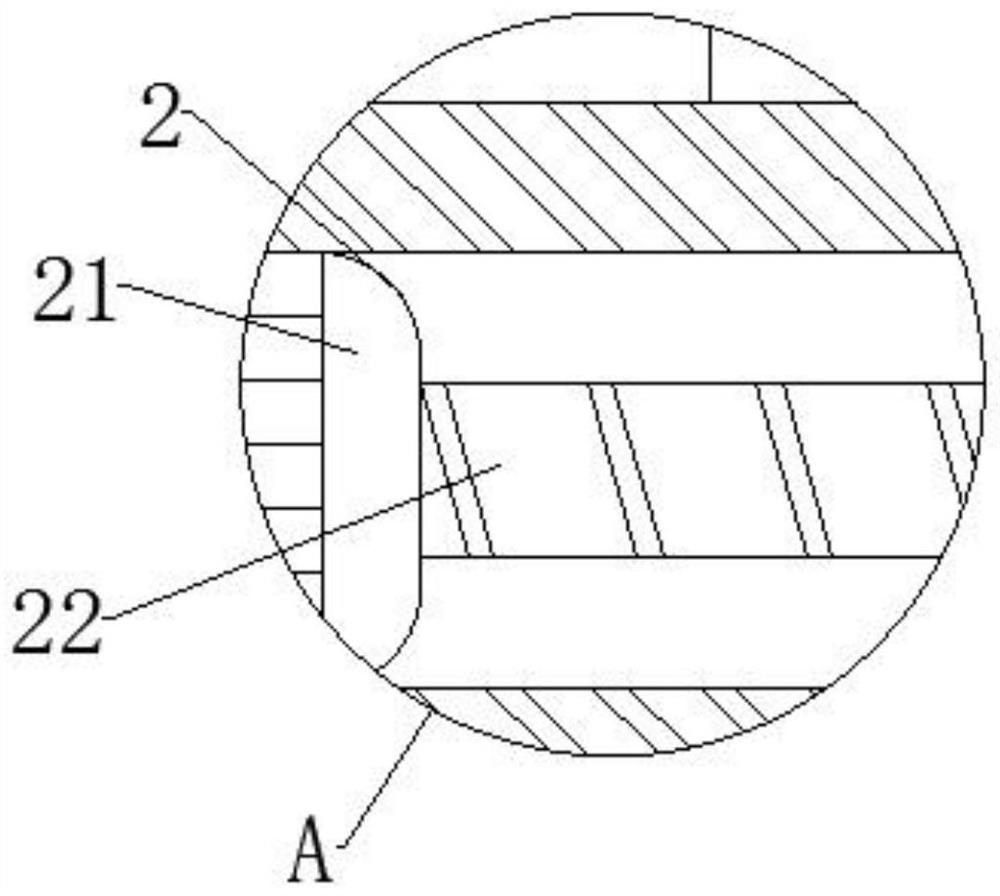

[0041] like Figure 1-8 As shown, the driving device 2 includes a driving motor 21, the output shaft of the driving motor 21 is fixedly connected with a translation screw 22, the outer wall of the translation screw 22 is movably connected with the inner wall of the mounting head 61, and the outer wall of the driving motor 21 is connected with the inner wall of the placing platform 1. Fixed connection.

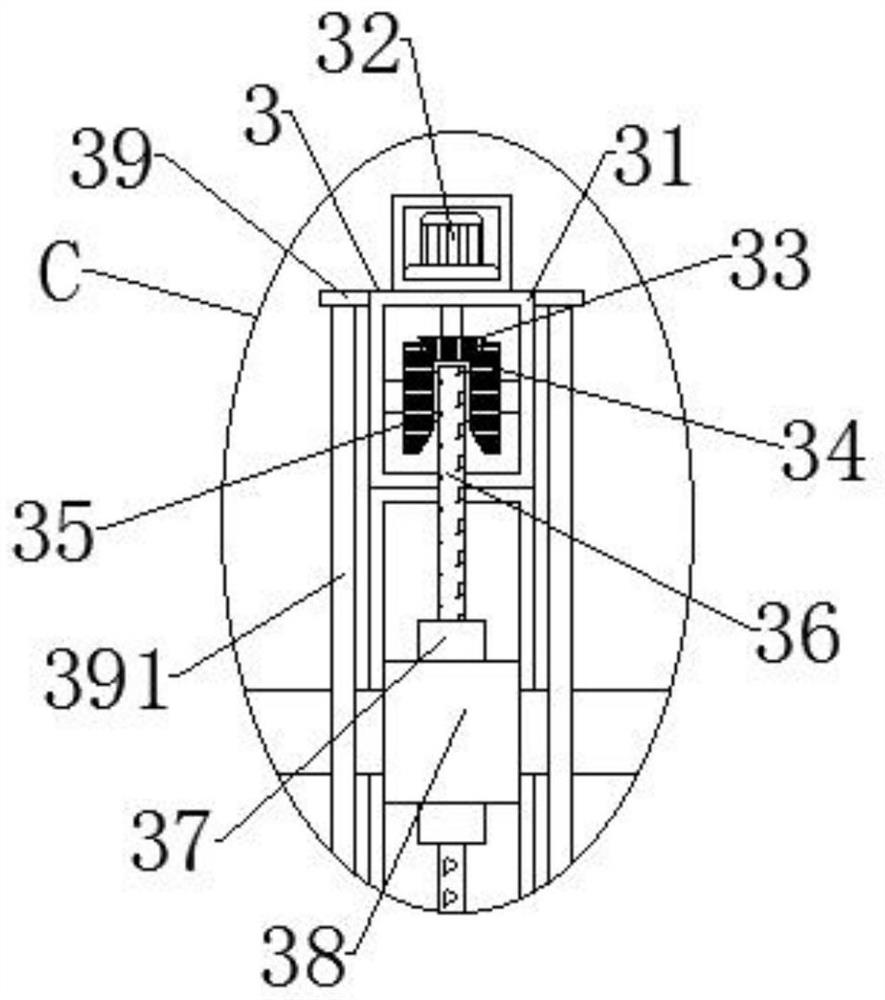

[0042] Preferably, the lifting device 3 includes a lifting groove 31, a lifting motor 32 is fixedly connected to the top of the lifting groove 31, a driving gear 33 is fixedly connected to the output shaft of the lifting motor 32, and a follower gear 34 is movably connected to the outer wall of the driving gear 33, The inside of the follower gear 34 is provided with a connecting shaft 35, the outer wall of the connecting shaft 35 is movably connected with a transmission belt 36, the outer wall of the transmission belt 36 is fixedly connected with a positioning block 37, and the...

Embodiment 3

[0045] like Figure 1-8 As shown, the rotating device 8 includes a rotating shaft 81, the top of the rotating shaft 81 is fixedly connected with the bottom surface of the placing platform 1, the bottom of the rotating shaft 81 is fixedly connected with a horizontal plate 82, and one side of the outer wall of the rotating shaft 81 is fixedly connected with a connecting seat 83, the connecting seat The bottom of 83 is fixedly connected to the limit vertical rod 84 , and the bottom of the outer wall of the limit vertical rod 84 is movably connected to the inner wall of the horizontal plate 82 .

[0046] Preferably, an installation groove 85 is fixedly connected to the bottom of the horizontal plate 82 , and a translation slider 86 is movably connected to the inner wall of the installation groove 85 . A rotating motor 88 is fixedly connected to the inner wall of 87 , and the output shaft of the rotating motor 88 is fixedly connected to the bottom of the rotating shaft 81 .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com