Eddy current braking device and braking method thereof

An eddy current braking and braking component technology, applied in electric braking systems, asynchronous inductive clutches/brakes, electric vehicles, etc., can solve the problem of low energy utilization rate of electromagnets, affecting the lightweight design of trains, loss of braking force, etc. problems, to reduce excess loss, reduce weight, and extend the life of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

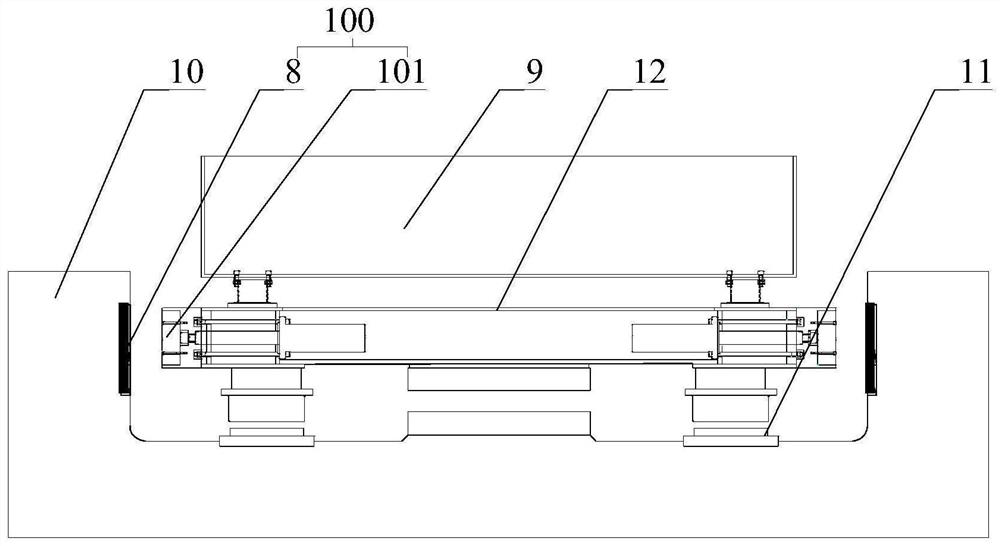

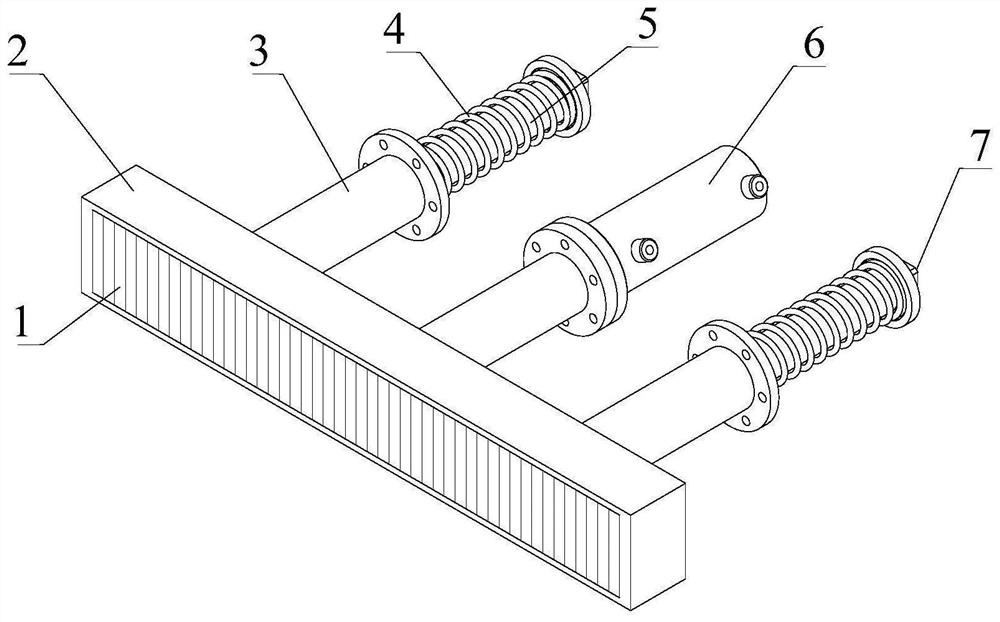

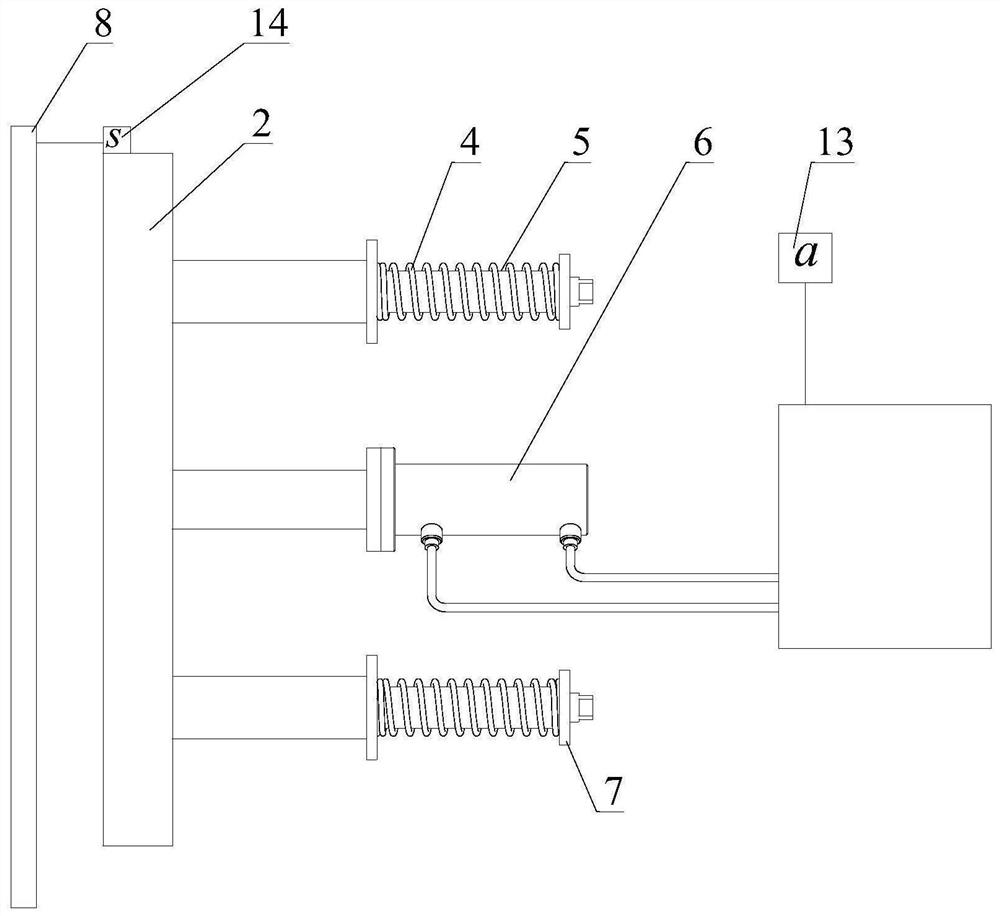

[0032] The present invention provides an eddy current braking device 100, comprising an induction plate 8 disposed on the inner wall of the track base 10 and braking assemblies 101 disposed on both sides of the suspension frame frame 12, the induction plate 8 along the track base 10 is arranged in the extension direction, and the induction plate 8 is made of conductive non-ferromagnetic material; wherein, the brake assembly 101 includes a lifting mechanism and a magnet base 2, and one end of the lifting mechanism is connected to the suspension frame 12. The outer surface perpendicular to the ground is connected; the magnet base 2 is connected to the other end of the lifting mechanism, the magnet base 2 and the induction plate 8 are located at the same height and parallel to each other, and the magnet base 2 is close to the induction A plurality of permanent magnets 1 are arranged on the surface of the plate 8 uniformly and without gaps along the extending direction of the track...

Embodiment 2

[0041] The present invention also provides a braking method of the eddy current braking device 100. The magnetic levitation train adopts the above-mentioned eddy current braking device 100 for braking, and the braking method includes:

[0042] When the magnetic levitation train is braked, the eddy current braking device 100 works so that the lifting mechanisms arranged on both sides of the suspension frame 12 reciprocate linearly along its axial direction; the magnet base 2 follows the movement of the lifting mechanism It is close to the induction plate 8 disposed on the inner wall of the track base 10 ; along with the movement of the suspension frame 12 , the magnet base 2 is moved relative to the induction plate 8 , and the induction plate 8 cuts the The magnetic field lines of the permanent magnet 1 on the magnet base 2 generate an eddy current; the eddy current generates a Loren magnetic force opposite to the driving direction of the vehicle body 9 under the action of the m...

Embodiment 3

[0044] This embodiment is based on the above-mentioned Embodiment 2, and the braking method of the eddy current braking device 100 further includes: the track base 10 is provided with different speed sections along the extending direction thereof, and different speed sections are set in different speed sections. The induction plate 8, the setting method of the induction plate 8 includes steps S1, S2, S3 and S4, wherein:

[0045] Step S1, obtain first information and second information, the first information is the preset driving speed corresponding to the current speed segment; the second information is the permanent magnet array in the magnet base 2 along the track The length information of the extension direction of the base 10, the permanent magnet array is arranged in a Halbach array. In this step, the preset driving speed in this section is determined according to various factors such as the development degree, line length, topography and geology and hydrological conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com