High-voltage line inspection unmanned aerial vehicle with high cruising ability

A high-voltage line, UAV technology, applied in overhead lines/cable equipment, motor vehicles, aircraft parts, etc., can solve problems such as poor UAV endurance, damage to UAV fan blades, UAV crashes, etc. , to achieve the effect of improving battery life, saving occupied area and avoiding crashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

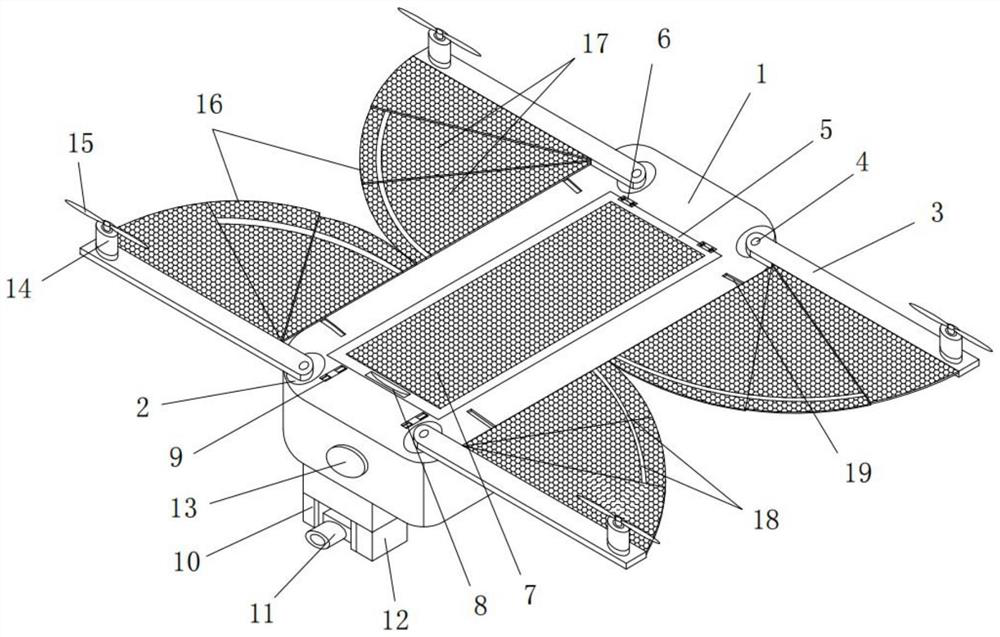

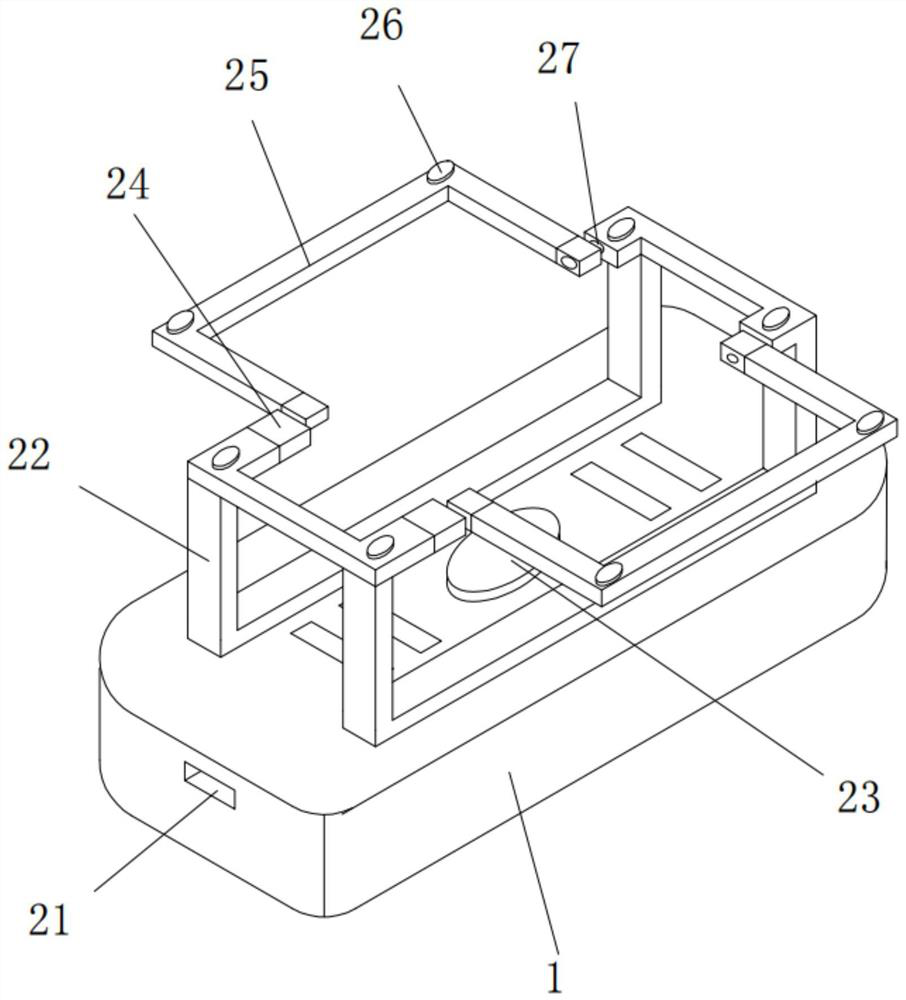

[0015] Embodiment 1: Combining Figure 1-Figure 3 This embodiment will be described. A high-endurance high-voltage line inspection drone described in this embodiment includes a drone body 1, a first solar panel 7, a camera 11, a first lighting lamp 13, four fourth A drive motor 2, four arm rods 3, four second drive motors 14, four fan blades 15, four movable panels 16 and a plurality of second solar panels 17; the housings of the four first drive motors 2 are installed On the four corners of the drone body 1, the first drive motor 2 is fixedly connected to one end of the arm rod 3 through the rotating shaft 4, the other end of the arm rod 3 is fixedly connected to the housing of the second drive motor 14, and the fan blade 15 It is fixedly installed on the second drive motor 14, the fixed end of the movable plate 16 is installed on the arm rod 3, the first solar panel 7 is fixedly installed on the top of the drone body 1, and each movable plate 16 is fixedly installed with a s...

specific Embodiment approach 2

[0016] Specific implementation mode 2: Combining Figure 1-Figure 2 Describing this embodiment, a high-endurance high-voltage line inspection drone described in this embodiment further includes a slot cover 5, a slot handle 8, two hinges 6 and two spring latches 9; the slot cover 5 One end of the two hinges 6 is rotatably connected to the battery slot 20, the other end of the slot cover 5 is installed with a groove handle 8, and the end of the slot cover 5 on which the groove handle 8 is installed is installed on the drone through a spring latch 9. On the side wall of the groove of the main body 1 , the first solar panel 7 is installed on the groove cover 5 . The first solar panel 7 is mounted on the top of the slot cover 5 by screws. A slot hole is provided on the slot cover 5, and a spring pin 9 is arranged in the slot hole, and the slot cover 5 is fixed on the top of the battery slot 20 through the spring pin 9 of the slot hole. Others are the same as the first embodiment...

specific Embodiment approach 3

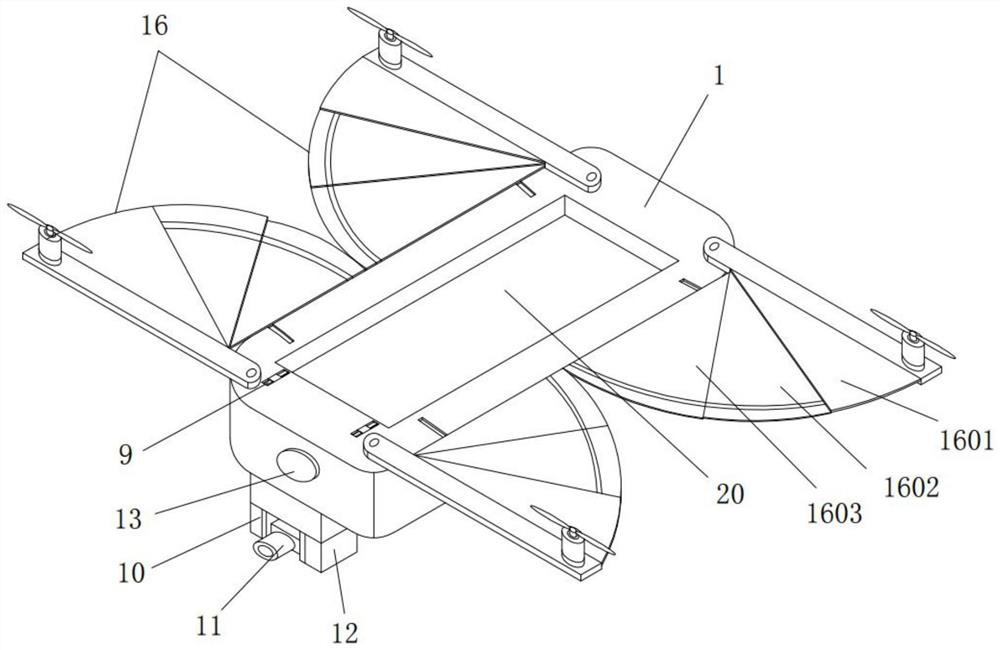

[0017] Specific implementation three: combination Figure 1-Figure 2 Illustrating this embodiment, a high-endurance high-voltage line inspection drone described in this embodiment, the movable plate 16 includes a first fan-shaped plate 1601, a second fan-shaped plate 1602 and a third fan-shaped plate 1603; the first fan-shaped plate 1603; One corner of 1601, one corner of the second sector plate 1602 and one corner of the third sector plate 1603 are all connected to the adjacent rotating shaft 4, and the bottom of the first sector plate 1601 and the bottom of the second sector plate 1602 are provided with a A slider, the second sector plate 1602 and the third sector plate 1603 are machined with a first chute 18, the first slider of the first sector plate 1601 is slidably arranged in the first slot 18 of the second sector plate 1602, The first slider of the second fan-shaped plate 1602 is slidably arranged in the first chute 18 of the third fan-shaped plate 1603 , the drone bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com