Method for improving alloy performance by adding Sc into Al-Cu alloy, material and application

An al-cu and alloy technology, applied in the field of aluminum alloys, can solve problems such as poor mechanical properties, achieve the effects of improving heat resistance, promoting precipitation strengthening, and improving recrystallization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

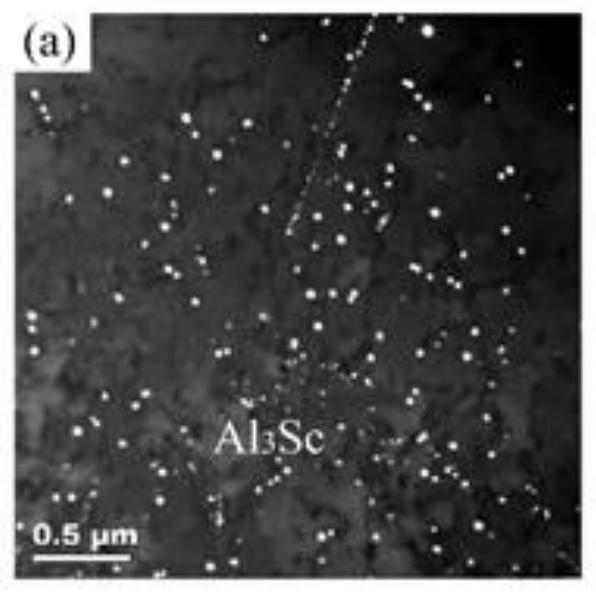

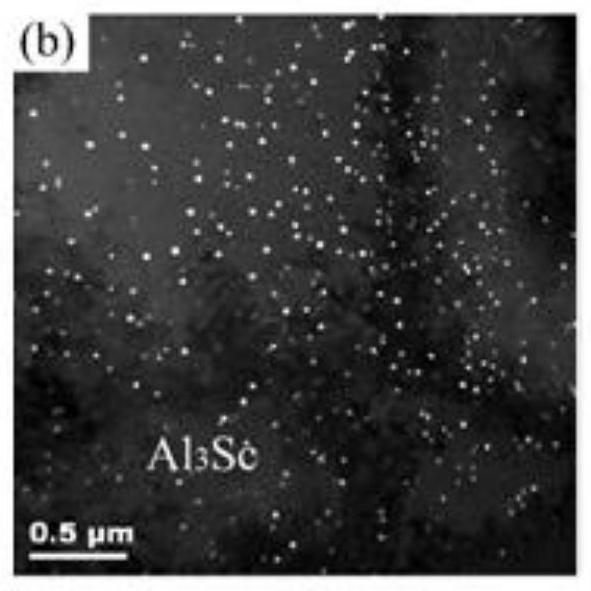

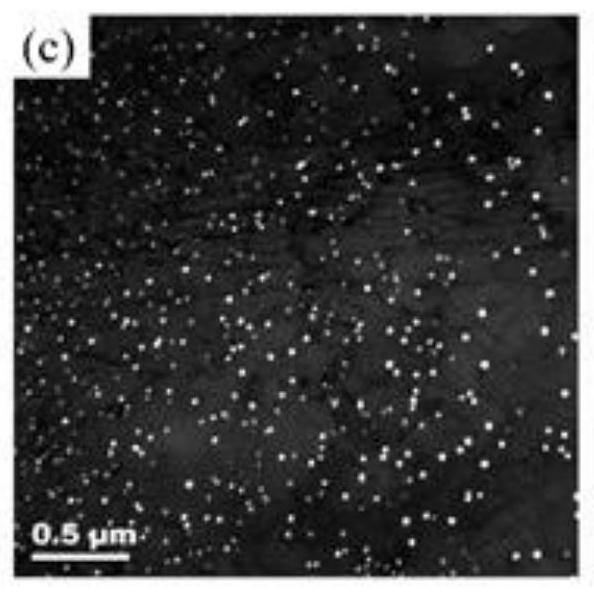

Image

Examples

Embodiment 1

[0033] A method for adding Sc to Al-Cu alloy to improve the properties of the alloy: comprising the following steps:

[0034] S1. Ingredients: prepare alloy raw materials according to the following alloy components and mass percentages, Cu is 4.5%, Sc is 0.15%, Mn is 0.02wt%, Fe is 0.05wt%, and the rest is Al;

[0035] Specifically, according to the calculation of smelting 5KG ingot, select Al-50Cu master alloy 0.45KG, Al-2Sc master alloy 0.375KG, and industrial pure aluminum 4.4KG;

[0036] S2. Melting: Add the prepared alloy raw materials to the resistance melting furnace for melting, and add Al-5Ti-1B grain refiner 20-30g to make the alloy composition more accurate;

[0037] S3. Casting: casting the smelted alloy melt into a mold, and cooling to obtain an alloy ingot;

[0038] S4. Peeling: remove the riser and uneven surface of the alloy ingot after casting, so that the surface of the alloy ingot is smooth;

[0039] S5. Double-stage homogenization treatment: double-stage ...

Embodiment 2

[0048] A method for adding Sc to Al-Cu alloy to improve the properties of the alloy: comprising the following steps:

[0049] S1. Ingredients: prepare alloy raw materials according to the following alloy components and mass percentages, Cu is 5%, Sc is 0.3%, Mn is 0.02wt%, Fe is 0.05wt%, and the rest is Al;

[0050] Specifically, according to the calculation of smelting 5KG ingot, select Al-50Cu master alloy 0.5KG, Al-2Sc master alloy 0.75KG, and industrial pure aluminum 4KG;

[0051] S2. Melting: add the prepared alloy raw material to the resistance melting furnace for melting, and add a purifying agent to make the alloy composition more accurate;

[0052] S3. Casting: casting the smelted alloy melt into a mold, and cooling to obtain an alloy ingot;

[0053] S4. Peeling: remove the riser and uneven surface of the alloy ingot after casting, so that the surface of the alloy ingot is smooth;

[0054] S5. Double-stage homogenization treatment: double-stage homogenization treatm...

Embodiment 3

[0063] A method for adding Sc to Al-Cu alloy to improve the properties of the alloy: comprising the following steps:

[0064] S1. Ingredients: prepare alloy raw materials according to the following alloy components and mass percentages, Cu is 6%, Sc is 0.5%, Mn is 0.02wt%, Fe is 0.05wt%, and the rest is Al;

[0065] Specifically, according to the calculation of smelting 5KG ingot, select Al-50Cu master alloy 0.6KG, Al-2Sc master alloy 1.25KG, and industrial pure aluminum 3.5KG;

[0066] S2. Melting: add the prepared alloy raw material to the resistance melting furnace for melting, and add a purifying agent to make the alloy composition more accurate;

[0067] S3. Casting: casting the smelted alloy melt into a mold, and cooling to obtain an alloy ingot;

[0068] S4. Peeling: remove the riser and uneven surface of the alloy ingot after casting, so that the surface of the alloy ingot is smooth;

[0069] S5. Double-stage homogenization treatment: double-stage homogenization trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com