Plaster processing pretreatment equipment

A pretreatment and equipment technology, applied in the field of plaster paste processing pretreatment equipment, can solve the problems of increasing plaster retention, plaster residue, and reduction of plaster efficacy, and achieve simple and ingenious structure, close connection between front and back work, and stable cooking environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

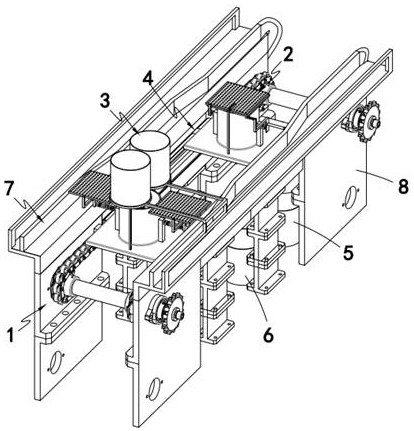

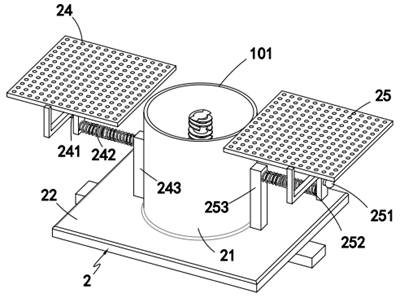

[0040] like figure 1 As shown, a pre-processing equipment for plaster sticker processing includes several groups of material-taking mechanisms 2 arranged at equal intervals on the transmission mechanism 1, and the material-acquisition mechanisms 2 pass through the batching mechanism 3, A brewing mechanism 4, a water collection tank 5 and a collection box 6;

[0041] The material taking mechanism 2 completes the automatic opening and closing of its opening 101 under the drive of the guide mechanism 7 .

[0042]In this implementation, the material taking mechanism 2 is arranged to cooperate with the batching mechanism 3 in turn to complete the receiving and soaking of the finished medicinal material 100 during the transmission process, and then cooperate with the boiling mechanism 4 to complete the boiling work of the medicinal material, and the medicinal material is placed in the medicinal material. After being boiled for 100 hours, the automatic separation of the ointment and...

Embodiment 2

[0065] The same or corresponding components in this embodiment and the above-mentioned embodiments are marked with corresponding reference numerals as in the above-mentioned embodiments. For the sake of simplicity, only the points of difference from the above-mentioned embodiments will be described below. The difference between this embodiment and the above-mentioned embodiment is:

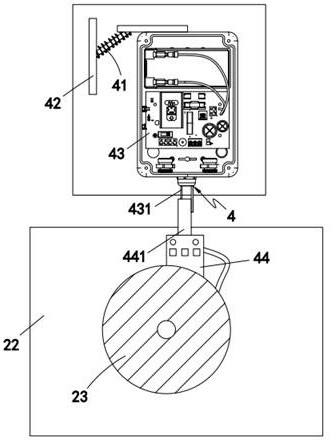

[0066] further, as Figure 7 to Figure 8 As shown, the batching mechanism 3 includes a medicinal material warehouse 31 and an oil warehouse 32. Both the medicinal material warehouse 31 and the oil warehouse 32 are provided with a material distribution unit 33 for intermittent discharge. The material distribution unit 33 includes a gap. The chassis 332 of 331 and the compartment 334 rotatably arranged on the chassis 332, the bottom of any compartment is coaxially provided with a drive wheel 333, and the drive wheel 333 is mounted on the base 22. 335 rotates intermittently under the drive of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com