Integrated busbar fireproof plate and battery pack

A busbar and fireproof board technology, applied in the field of battery systems, can solve the problems of complex manufacturing process and structure, low thermal runaway resistance, large space occupation, etc., to improve energy density and space utilization, compact structure, and space occupation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

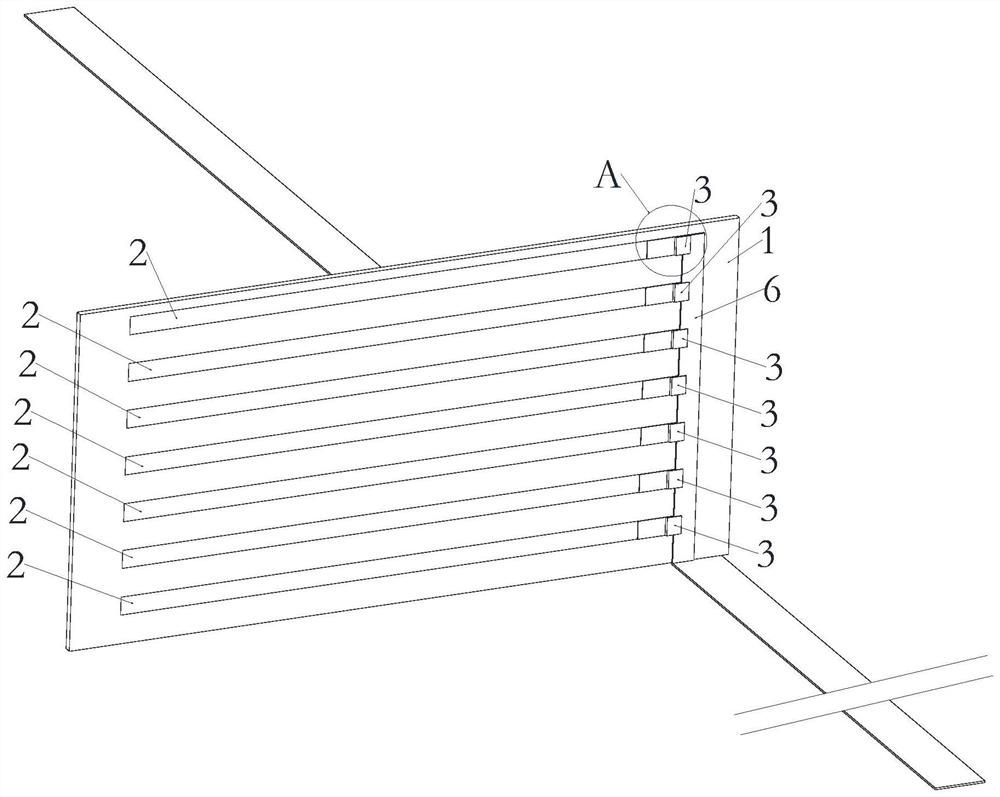

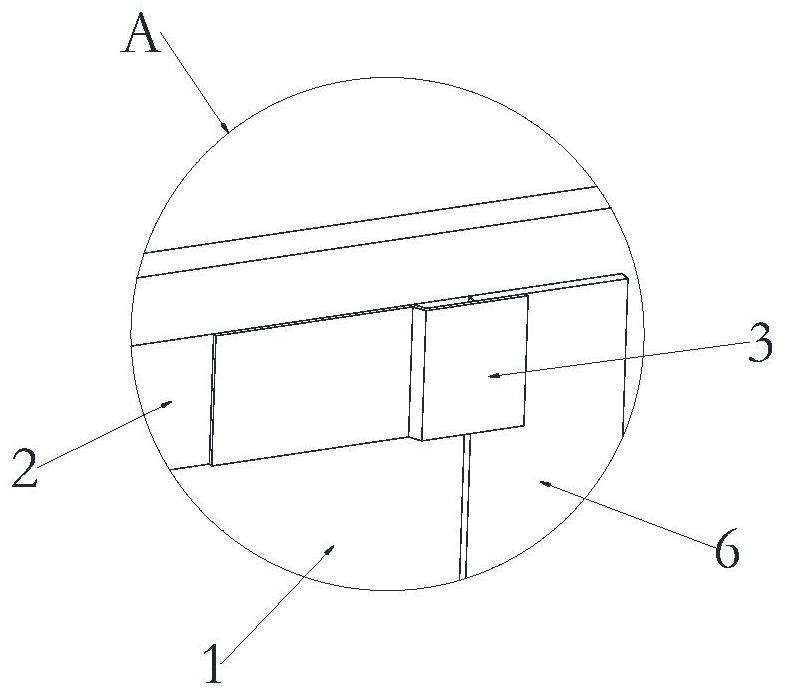

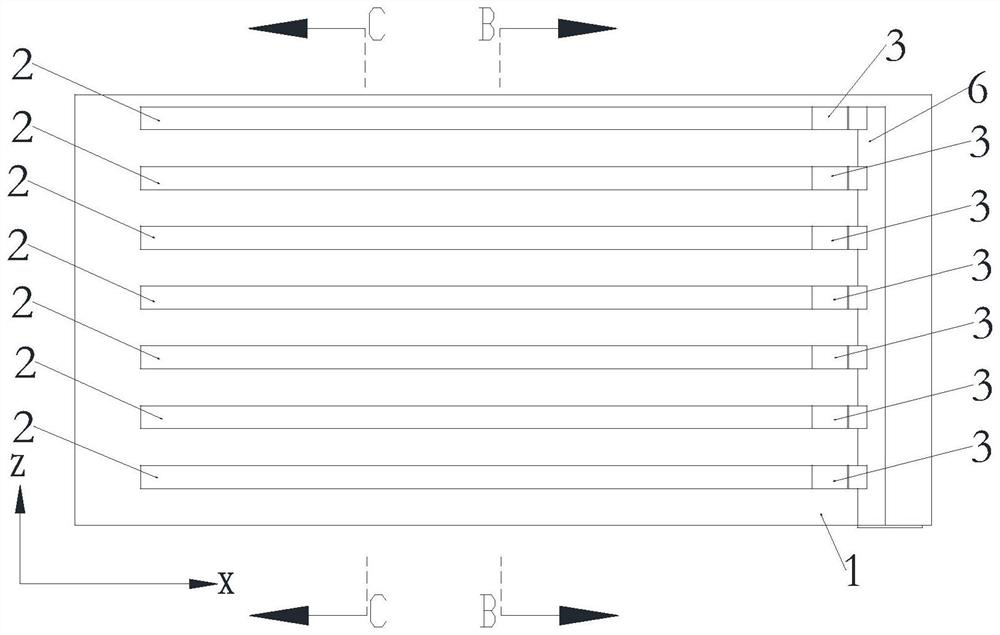

[0080] like Figure 1 to Figure 5 As shown, a fireproof board integrated with busbars in this embodiment includes a fireproof board body 1 and a busbar 2. The fireproof board body 1 is integrally assembled with one or more busbars 2. The busbars 2 has a tab connection surface for connecting the cell tabs 51 ; that is, the tab connection surface of the bus bar 2 is exposed or protruded from the fireproof board body 1 and is used for connecting the cell tabs 51 .

[0081] like Figure 1 to Figure 5 As shown, the bus bar 2 of this embodiment is embedded in the fireproof board body 1, and the surface of the fireproof board body is provided with a tab connecting surface of the busbar to be exposed from the fireproof board body or Protruding cutout 11. The integration between the bus bar 2 and the fireproof board body 1 may adopt the structural form in which the busbar 2 is embedded in the fireproof board body 1, so as to make the structure compact and provide effective and stable...

specific Embodiment approach 1

[0084] Embodiment 1: The fireproof board body 1 is a multi-layer board pressing structure, and the bus bar 2 is pressed and embedded between two adjacent layer board structures; for example, two-layer boards can be used, and each layer board A placement slot for placing the bus bar 2 is opened, and a hollow 11 for at least a part of the surface of the bus bar 2 to be exposed at the bottom of the slot is opened, and then the two layers of boards are pressed into a whole by the equipment, so that the bus bar 2 is clamped Set inlaid between two layers of boards. Of course, for consideration of other processes or structures, more than three layers of plates can also be used for pressing, as long as the inlay of the bus bars 2 and the exposure of the surfaces of the bus bars can be satisfied.

specific Embodiment approach 2

[0085] Embodiment 2: The fireproof board body 1 is a multi-layer laminated structure, the bus bar 2 is sandwiched between two adjacent two-layer laminated structures, and / or between the multi-layer laminated structures The multi-layer board stacking structure and the bus bar 2 are connected and fixed by connecting pieces, that is, the multi-layer board stacking structure can be fixed by connecting pieces, or the multi-layer board structure and the bus bar 2 can be connected. The multi-layer board stacking structure can also be fixed by the first connector, and then the multi-layer board structure and the bus bar 2 can be fixed by the second connector, as long as the bus bar 2 can be stabilized It can be sandwiched between adjacent two-layer board structures. For example, two layers of boards can be used, and a placement slot for placing the bus bar 2 is provided on each layer, and a hollow 11 for exposing at least a part of the surface of the bus bar 2 is provided at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com