Water sample pretreatment filtering device for environmental monitoring laboratory

A technology for sample pretreatment and filtration device, applied in the field of environmental monitoring experiments, can solve the problems of easy clogging, decreased fluidity of water samples in the filter plate, and reduced filtering effect of other impurities in water samples, so as to avoid clogging of impurities and improve the The effect of filtering, the effect of improving the time of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

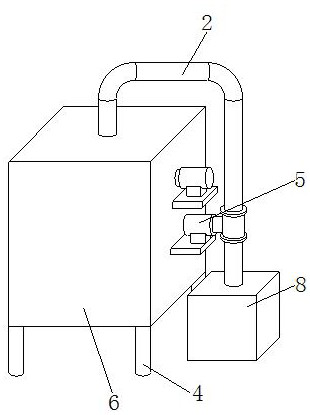

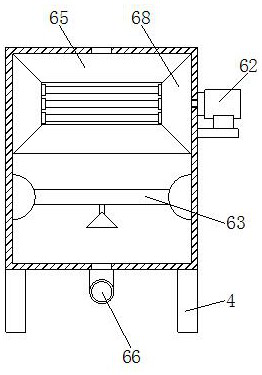

[0022] as attached figure 1 to the attached Figure 5 shown:

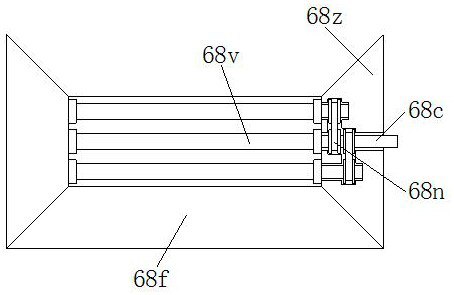

[0023] The present invention is a water sample pretreatment and filtering device for environmental monitoring laboratory. The water pump 5 is installed on the lower right end of the suction pipe 2, and the upper left end of the suction pipe 2 is installed on the top of the filter device 6 and communicates with each other. The four corners of the filter device 6 are welded with supporting feet 4. The filter device 6 includes a filter box 65, a motor 62, an adsorption mechanism 68, a filter plate mechanism 63, and a drain pipe 66. The upper left end of the suction pipe 2 is installed on the top of the filter box 65 and communicates with each other. There is a motor 62, and the output end of the motor 62 is connected with the internal drive of the adsorption mechanism 68. The adsorption mechanism 68 is installed on the upper end of the inner side of the filter box 65. The four corners of the bottom of the filter box...

Embodiment 2

[0030] as attached Image 6 to the attached Figure 7 shown:

[0031] The filter plate mechanism 63 includes a support plate 63d, a top rod 63z, a positioning ball 63w, an outer frame 63b, a filter plate 63g, and a swing mechanism 63t. The support plate 63d is welded to the lower end of the filter box 65, and the support plate 63d The upper end is welded with the lower end of the ejector rod 63z, the upper end of the ejector rod 63z is provided with a positioning ball 63w, and the positioning ball 63w is installed at the inner middle end of the outer frame 63b by clearance fit, and the outer frame 63b is embedded with a filter plate 63g. The outer end of the outer frame 63b is installed inside the swing mechanism 63t, and the outer end of the swing mechanism 63t is fixedly installed inside the filter box 65. The filter plate 63g is located below the ejection mechanism 68f. It is symmetrically installed on both sides of the outer frame 63b, and the inner center of the outer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com