Photocatalytic reactor

A photocatalytic reactor and catalyst-loaded technology, applied in the field of reactors, can solve the problems of matching and actual utilization gap, and achieve the effect of high effective irradiation intensity, high-efficiency catalytic effect, and volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

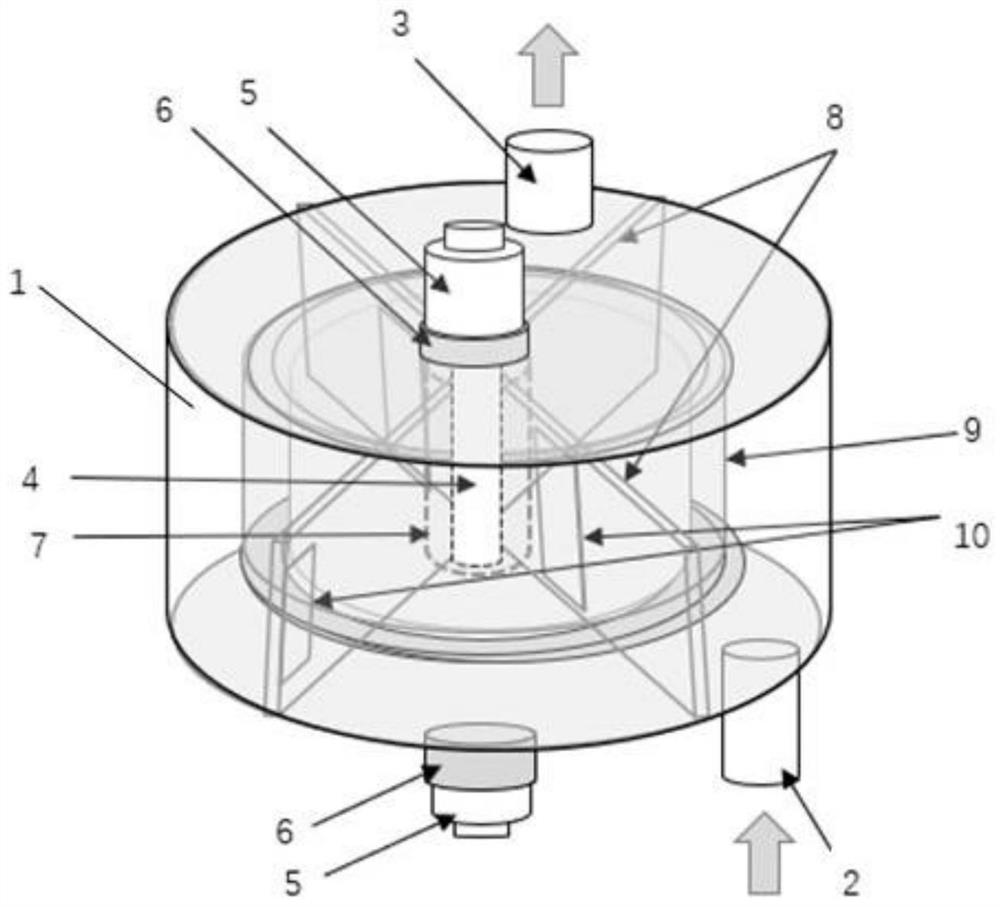

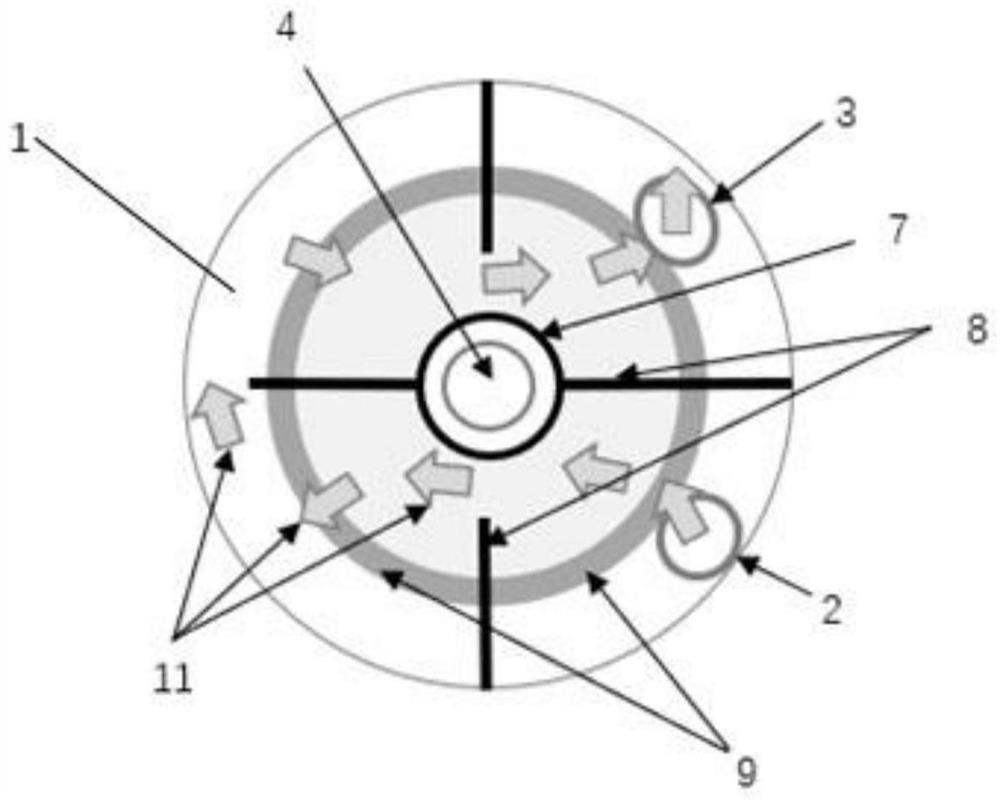

[0059] like figure 1 and figure 2 As shown, a photocatalytic reactor includes a shell, the shell is provided with a hollow cavity 1, a medium inlet 2 is provided on one side of the lower end of the shell, and a medium inlet 2 is provided on the side of the upper end of the shell There is a medium outlet 3;

[0060] The upper end and the lower end of the casing are respectively provided with a through hole for accommodating the lamp cap 5, and the lamp 4 passes through the through hole on the casing and is connected with the lamp holder, which is connected to the lamp holder. The casing is fixedly connected, a sealing ring 6 is arranged between the lamp cap 5 and the casing, and the light-emitting section of the lamp 4 is arranged in the cavity 1;

[0061] In the cavity 1, four partitions 8 are arranged along the axial direction of the lamp tube 4. The partitions 8 are provided with medium passage windows 10, and the adjacent medium passage windows 10 are arranged in a stagg...

Embodiment 2

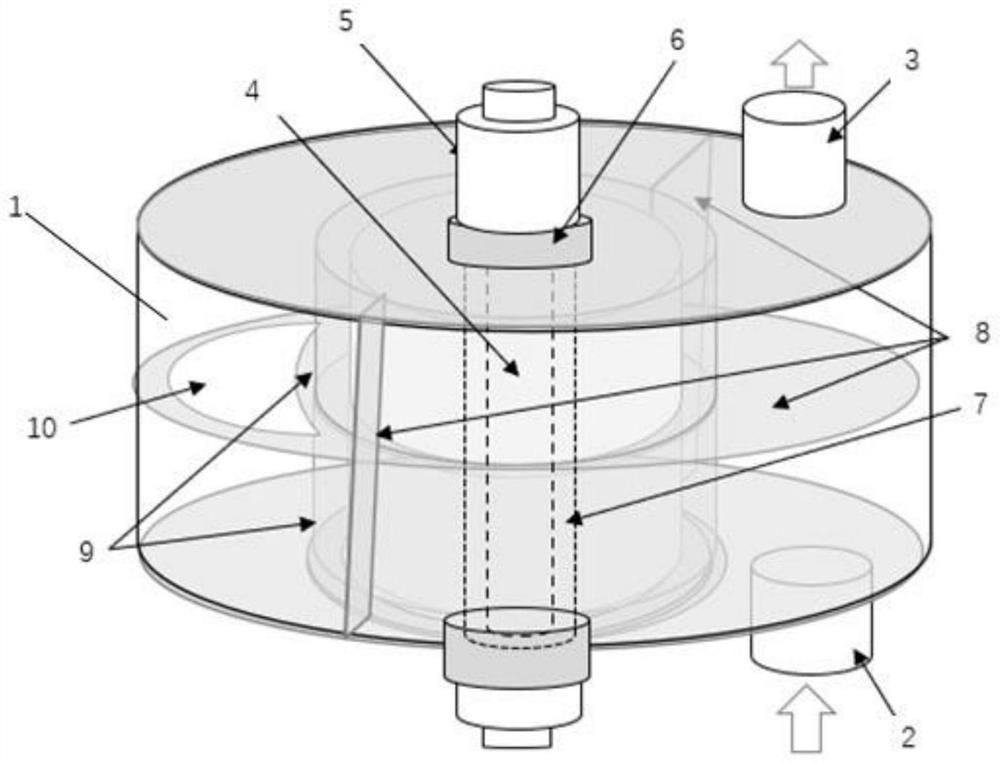

[0076] like image 3 and Figure 4 As shown in the figure, a photocatalytic reactor includes a shell, the shell is provided with a hollow cavity 1, a medium inlet 2 is provided on one side of the lower end of the shell, and one side of the lower end of the shell is provided with a medium inlet 2. There is a medium outlet 3;

[0077] The upper and lower ends of the casing are provided with a through hole for accommodating the lamp cap 5, and the lamp 4 passes through the through hole on the casing and is connected with the lamp holder, the lamp holder is connected to the lamp holder. The casing is fixedly connected, a sealing ring 6 is arranged between the lamp cap 5 and the casing, and the light-emitting section of the lamp 4 is arranged in the cavity 1;

[0078] A partition member 8 is arranged in the cavity 1 along the radial direction of the lamp tube 4, and a medium passage window 10 is arranged on the partition member 8. The medium inlet 2, the medium passage window 10,...

Embodiment 3

[0092] like Figure 5 and Image 6 As shown, Embodiment 3 is roughly the same as Embodiment 2, the only difference being:

[0093] 1. There are two medium inlets 2 on the lower side of the casing, and two medium outlets 3 on the upper side of the casing;

[0094] 2. In the cavity 1, a partition member 8 is provided along the axial direction and the radial direction of the lamp tube 4 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com