Double-quick-opening wet-type withdrawal and straightening machine

A tension leveling machine and wet type technology, applied in the field of double quick-opening wet tension leveling machines, can solve the problems of damage, lack of quick opening function of the lower bending roll box, etc., to improve the working environment, good sealing performance, and improve the recycling rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

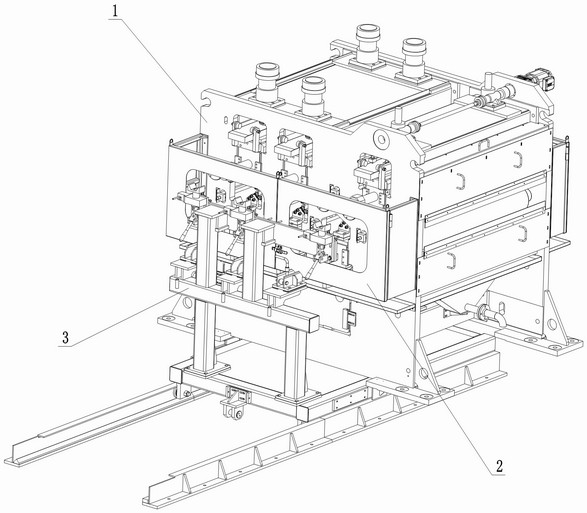

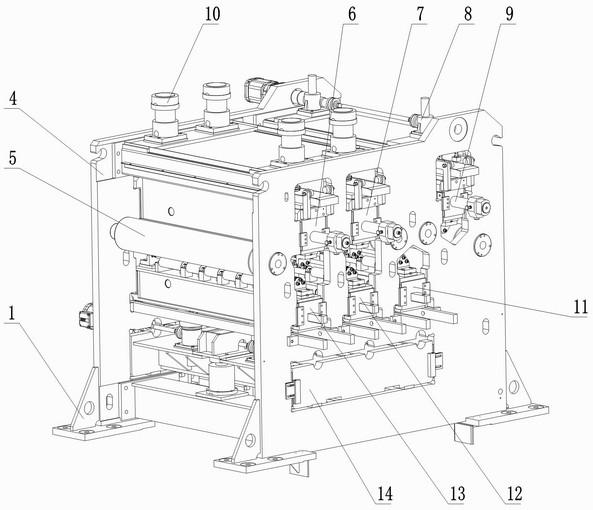

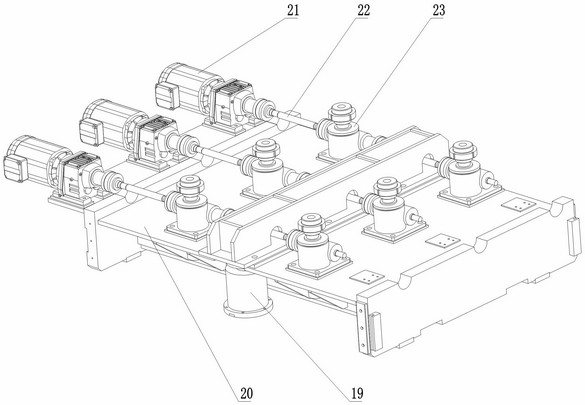

[0020] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the sealing device 2 of the present invention is installed at the bottom of the frame 4, and the sealing device 2 connects the frame 4 and the upper bending roller box one 6, the upper bending roller box two 7, the upper straightening roller box 9, the lower straightening roller The box 11, the lower bending roller box 1 12 and the lower bending roller box 2 13 are surrounded by the surrounding, the sealing device 2 is composed of an inlet baffle 24, an outlet baffle 28, a transmission side sealing door 27 and an operation side sealing door 30 to form a closed cavity, It can block the splashing desalinated water, solve the problem of splashing of desalinated water, and improve the working environment of the tension leveler; the sealing device 2 is provided with a plurality of jet pipes 26, and the water receiving tray 25 is installed at the bottom of the sealing device 2. , the recovery pipe join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com