Method for efficiently eliminating residual stress of welded plate and implementation device thereof

A residual stress and plate technology, which is applied to the improvement of process efficiency, heat treatment process control, furnace, etc., can solve the problems of long cycle, high energy consumption, time-consuming and labor-consuming, etc., and achieve residual stress elimination, energy saving, and elimination of residual The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

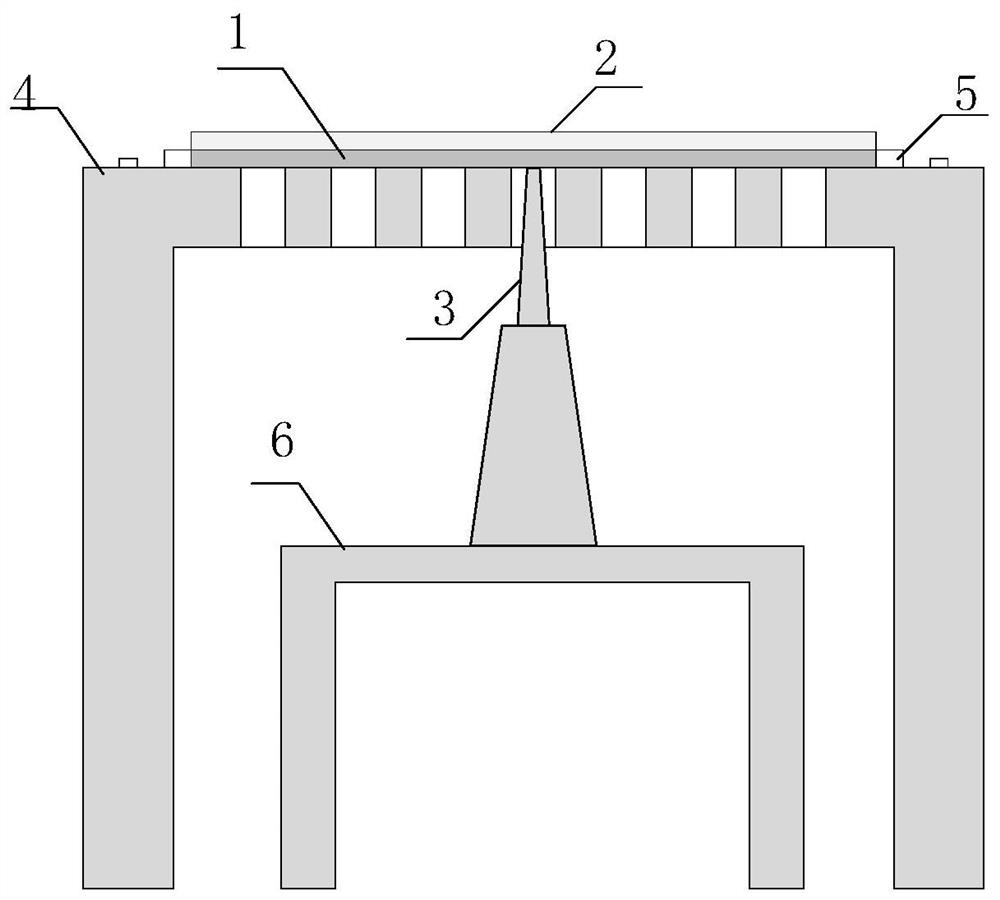

[0022] A method for efficiently eliminating residual stress of a welded plate, the welded plate is a 316L stainless steel welded plate with a thickness of 6 mm, and the method for eliminating residual stress is: covering a flexible heating plate on the welded plate to ensure that the coverage area includes all the welding seams Area, fusion area and heat affected area, the flexible heating plate is heated to the set temperature and kept warm, the temperature of the welded plate is monitored by the temperature sensor, when the temperature of the lower surface of the welded plate reaches the set temperature of the flexible heating plate, the bottom of the welded plate is heated to the bottom of the welded plate. Apply ultrasonic vibration, stop heating while ultrasonic vibration is stopped, and cool the welded plate in the air to room temperature, that is, to complete the elimination of residual stress;

[0023] The set temperature of the flexible heating plate is 170°C; the heat...

Embodiment 2

[0031] A method for efficiently eliminating residual stress of a welded plate, the welded plate is a 316L stainless steel welded plate with a thickness of 1 mm, and the method for eliminating residual stress is: covering a flexible heating plate on the welded plate to ensure that the coverage area includes all the welding seams Area, fusion area and heat affected area, the flexible heating plate is heated to the set temperature and kept warm, the temperature of the welded plate is monitored by the temperature sensor, when the temperature of the lower surface of the welded plate reaches the set temperature of the flexible heating plate, the bottom of the welded plate is heated to the bottom of the welded plate. Apply ultrasonic vibration, stop heating while ultrasonic vibration is stopped, and cool the welded plate in the air to room temperature, that is, to complete the elimination of residual stress;

[0032] The set temperature of the flexible heating plate is 150°C; the heat...

Embodiment 3

[0036]A method for efficiently eliminating residual stress of a welded plate, the welded plate is a 316L stainless steel welded plate with a thickness of 20mm, and the method for eliminating residual stress is: covering a flexible heating plate on the welded plate to ensure that the coverage area includes all the welding seams Area, fusion area and heat affected area, the flexible heating plate is heated to the set temperature and kept warm, the temperature of the welded plate is monitored by the temperature sensor, when the temperature of the lower surface of the welded plate reaches the set temperature of the flexible heating plate, the bottom of the welded plate is heated Apply ultrasonic vibration, stop heating while ultrasonic vibration is stopped, and cool the welded plate in the air to room temperature, that is, to complete the elimination of residual stress;

[0037] The set temperature of the flexible heating plate is 180°C; the heating rate of the flexible heating pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com