Thrust type CVT (continuously variable transmission) mechanical continuously variable transmission with transmission ratio of 5-15 for electric automobile

A technology of continuously variable transmission and electric vehicles, applied in electric vehicles, transmissions, mechanical equipment, etc., can solve the problems of large volume and power of motors and controllers, double-stage multi-stage reducer shifting frustration, motor speed maintenance, etc. , to avoid a sharp drop in efficiency torque, simple structure, and reduce the motor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

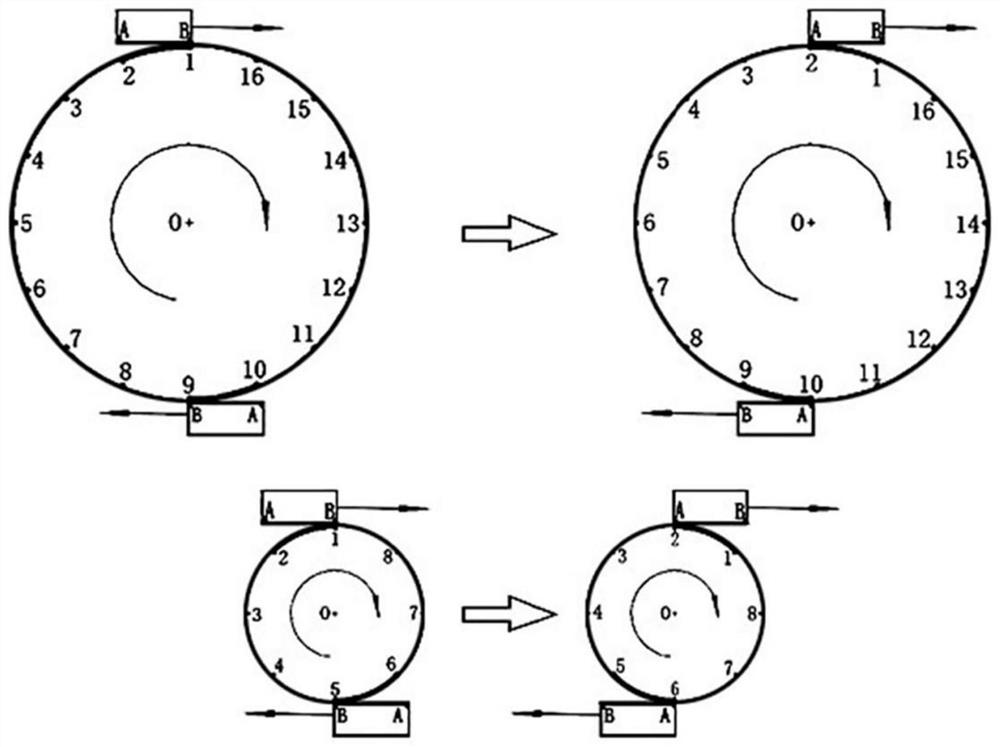

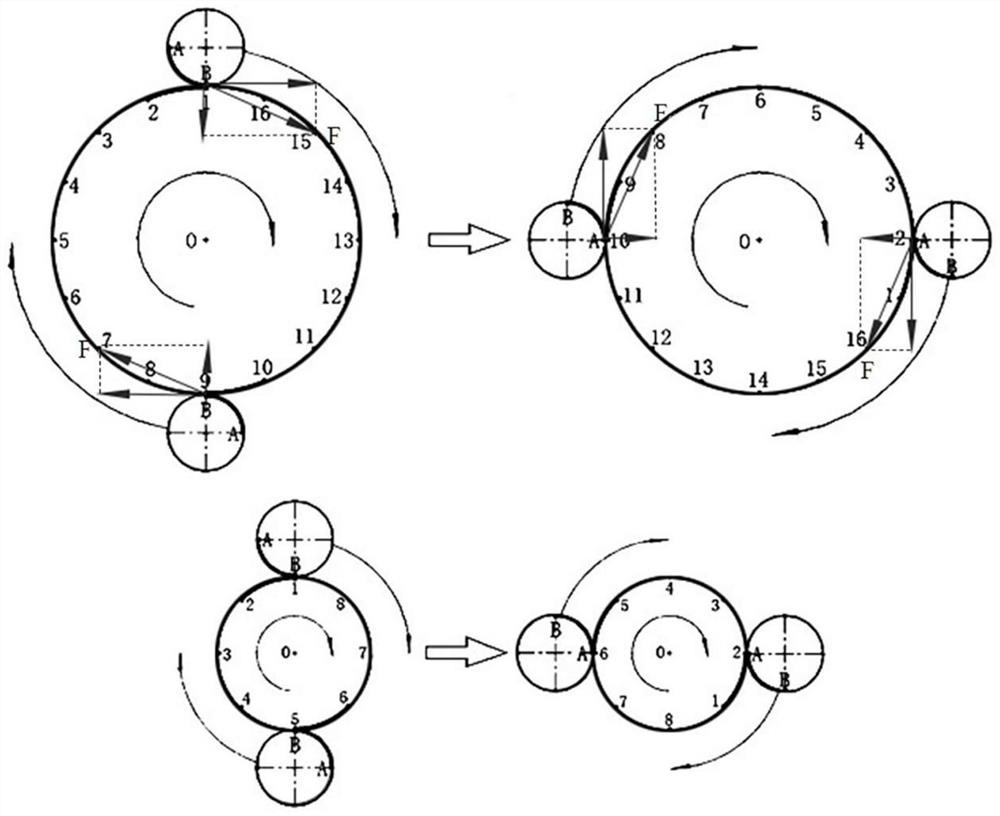

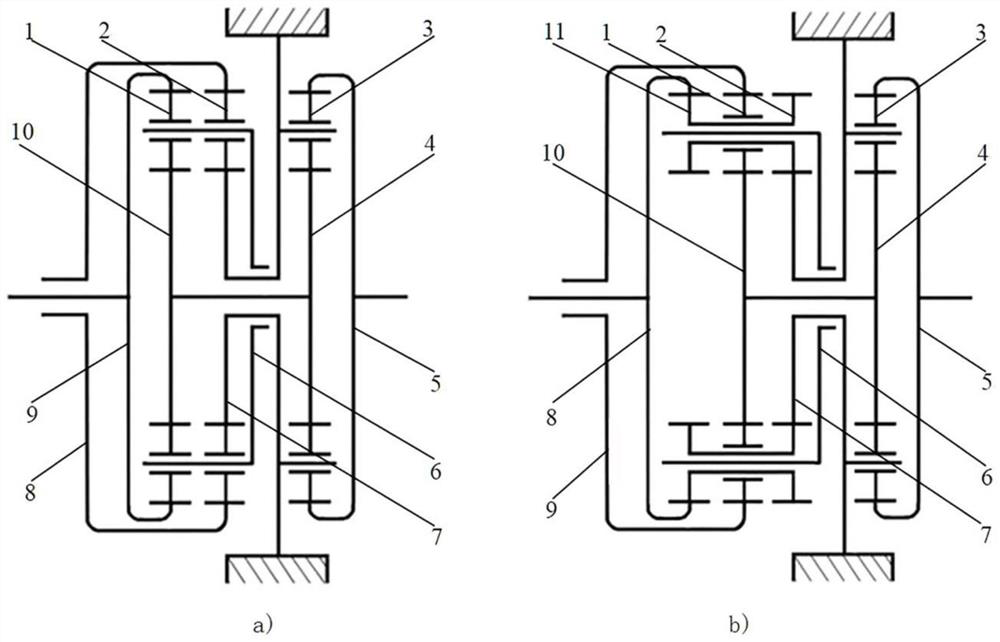

[0024] Thrust CVT mechanical continuously variable transmission includes: input part, driving wheel part, control part of driving wheel not rotating, driving wheel radial displacement control part, output bevel wheel and its left and right bevel wheel separation and close control part, planetary gear output Part and other 6 parts. like Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 Shown: the input part is composed of the input shaft 16, the right drive disc 19 fixedly connected with the input shaft, and the left drive disc 21 set on the sleeve of the central fixed control gear 24, and the drive disc is machined with and actively pushed There are arc guide slots with the same number of wheels, and the driving discs 19 and 21 are fixedly connected by the two ends of the intermediate idler shaft 25; Between the drive discs 19 and 21, the two ends of the push wheel shaft 20 are inserted into the arc guide grooves on the drive disc, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com