Enameled wire, production process thereof and transformer adopting enameled wire

A production process and technology of enameled wire, applied in the field of enameled wire, can solve problems such as difficulty in adapting to light weight, low power consumption and high performance, limiting the application of copper-clad aluminum enameled wire, and unstable operation of electrical products, so as to improve work stability and improve integration Firmness, simple and reliable process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

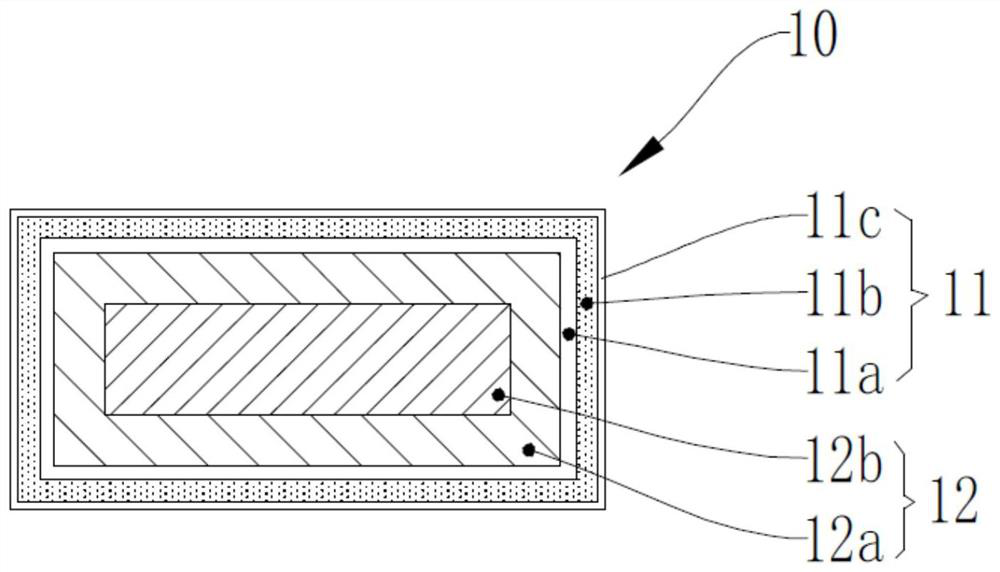

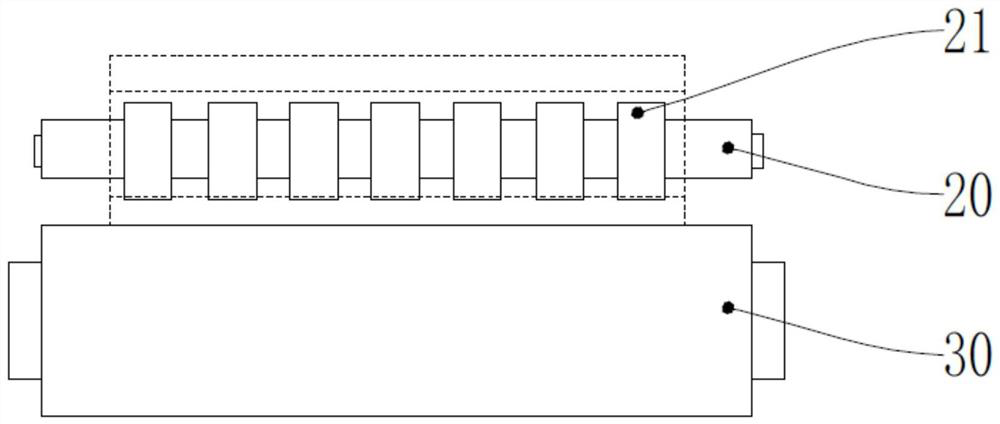

[0100] Example 1 lacquer bag and its production process and transformer

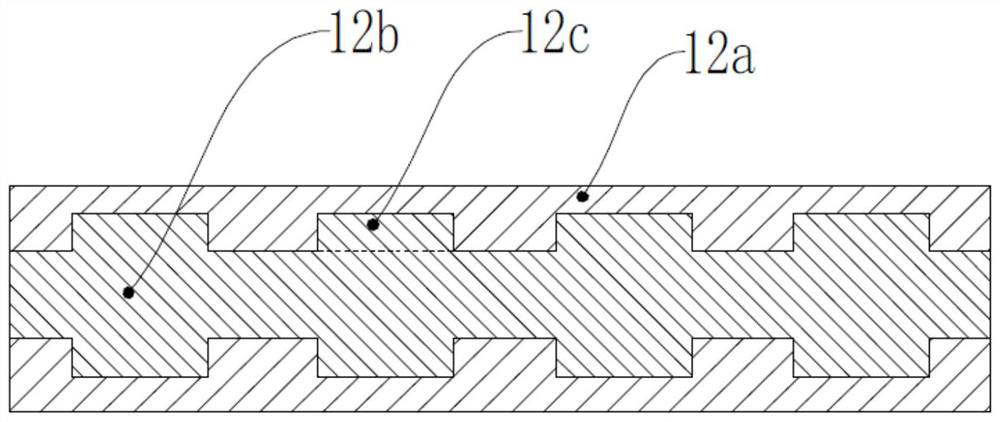

[0101]The lacquer cable of this embodiment consists of the core wire and the paint layer, and the paint layer is wrapped outside the core wire. The core wire is a flat wire, and the core wire includes the copper layer and aluminum core, and the copper layer is wrapped outside the aluminum core. The width and length of the cross section of the core wire is 2mm and 10mm, and the depth of the ring groove is 0.6mm. The outer surface of the core wire is organically treated with a phenytic sedimentary coating method with a phenyate melamine on the surface of the core wire.

[0102] The paint layer includes the bottom paint layer, mid -paint layer and external paint layer set from the inside out.

[0103] Mass quality percentage:

[0104] The raw materials of the bottom paint layer include 20 % melamine polymiol, 50 % phenolic resin, 6 % heating fillers, 1 % of triaxy hydroxymel propylene, and 20 % of marshide glyc...

Embodiment 2

[0129] Example 2 lacquer packs and their production processes and transformers

[0130] The lacquer cable of this embodiment consists of the core wire and the paint layer, and the paint layer is wrapped outside the core wire. The core wire is a flat wire, and the core wire includes the copper layer and aluminum core, and the copper layer is wrapped outside the aluminum core. The width and length of the cross section of the core wire are 2mm and 8mm, and the depth of the ring groove is 0.4mm. The outer surface of the core wire is organically treated with a methamphetamine on a gas -phase sedimentation coating.

[0131] The paint layer includes the bottom paint layer, mid -paint layer and external paint layer set from the inside out.

[0132] Mass quality percentage:

[0133] The raw materials of the bottom paint layer include 25 % melamine polymiol, 35 % phenolic resin, 5 % heating fillers, 2 % of triaxy hydroxyl propylene, and 30 % and 3 % of the auxiliary agent;

[0134] The raw ...

Embodiment 3

[0158] Example 3 lacquer packs and their production processes and transformers

[0159] The lacquer cable of this embodiment consists of the core wire and the paint layer, and the paint layer is wrapped outside the core wire. The core wire is a flat wire, and the core wire includes the copper layer and aluminum core, and the copper layer is wrapped outside the aluminum core. The width and length of the cross section of the core wire are 5mm and 20mm, and the depth of the ring groove is 1mm. The outer surface of the core wire is organically treated with a polyimide resin and phenolic resin to organically treat the core wire surface.

[0160]The paint layer includes the bottom paint layer, mid -paint layer and external paint layer set from the inside out.

[0161] Mass quality percentage:

[0162] The raw materials of the bottom paint layer include 25 % melamine polymiol, 45 % phenolic resin, 5 % heating fillers, 3 % of triaxy hydroxyl propylene, and 20 % and 2 % of the auxiliary ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com