M50 bearing steel bar and preparation method thereof

A bearing steel, bar technology, used in metal rolling, temperature control, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] On the one hand, an embodiment of the present invention provides a method for preparing an M50 bearing steel bar, which includes the following steps:

[0048] The step of preparing a consumable ingot: performing a vacuum consumable remelting process on the ingot to prepare a consumable ingot; wherein, the equivalent diameter size of a single carbide in the consumable ingot is less than 150 μm, and in the consumable ingot: carbonization The content of M2C carbide in the material is ≥95%.

[0049] In this step, the ingot refers to the ingot obtained after vacuum induction melting. Here, by controlling the vacuum consumable remelting process, the equivalent diameter size of a single carbide in the obtained consumable ingot is less than 150 μm, and in the consumable ingot: the content of M2C carbide in the carbide ≥95%.

[0050] Specifically, in this step, the depth of the center of the molten pool and the diameter of the consumable ingot are mainly controlled to be 0.5-0...

Embodiment 1

[0061] The present embodiment prepares a kind of M50 bearing steel bar, and the main steps are as follows:

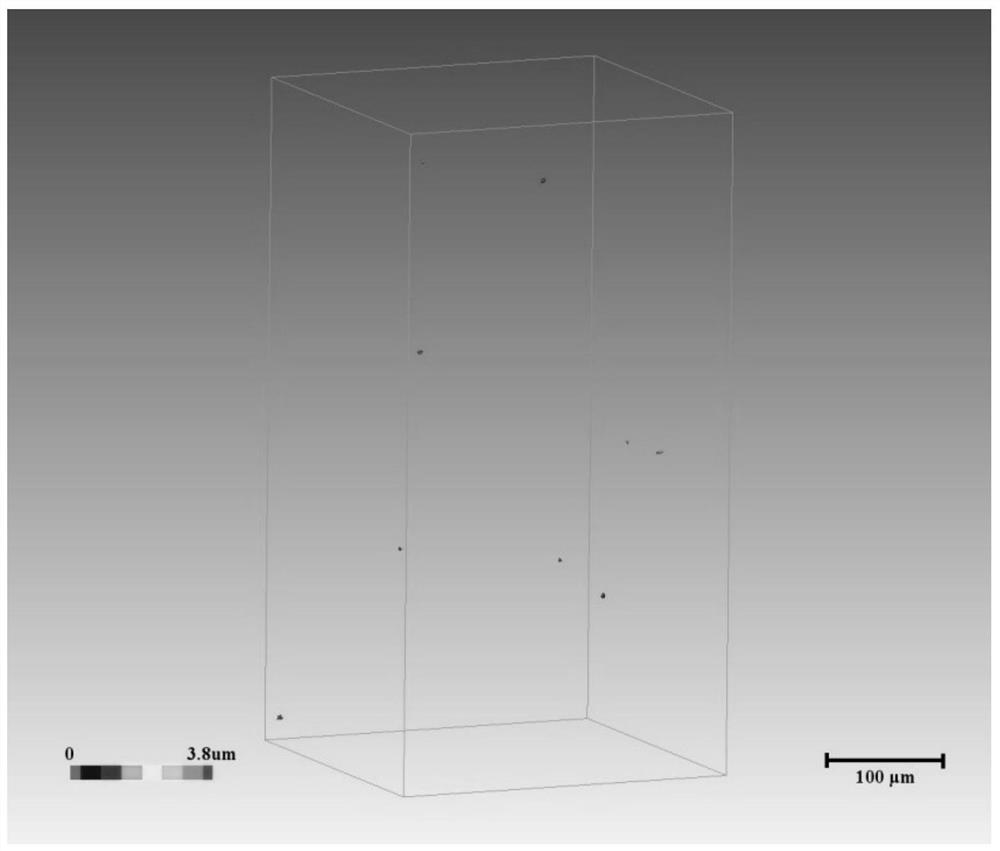

[0062] The step of preparing a consumable ingot: performing vacuum consumable remelting treatment on the ingot after vacuum induction melting to prepare a consumable ingot. Specifically, a Φ380mm ingot was used as the electrode blank, and vacuum consumable remelting treatment was carried out; wherein, during the vacuum consumable remelting treatment process, the melting power was adjusted and the mold was forced to cool, and the gap was increased under the condition of water cooling of the mold. Air-cooled, so that the depth / width of the molten pool (the depth refers to the depth of the center of the molten pool; the width refers to the diameter of the consumable ingot) is controlled to be 0.65.

[0063] Wherein, the equivalent diameter size of the carbide in the consumable ingot prepared in this step is less than 150 μm.

Embodiment 2

[0071] The present embodiment prepares a kind of M50 bearing steel bar, and the main steps are as follows:

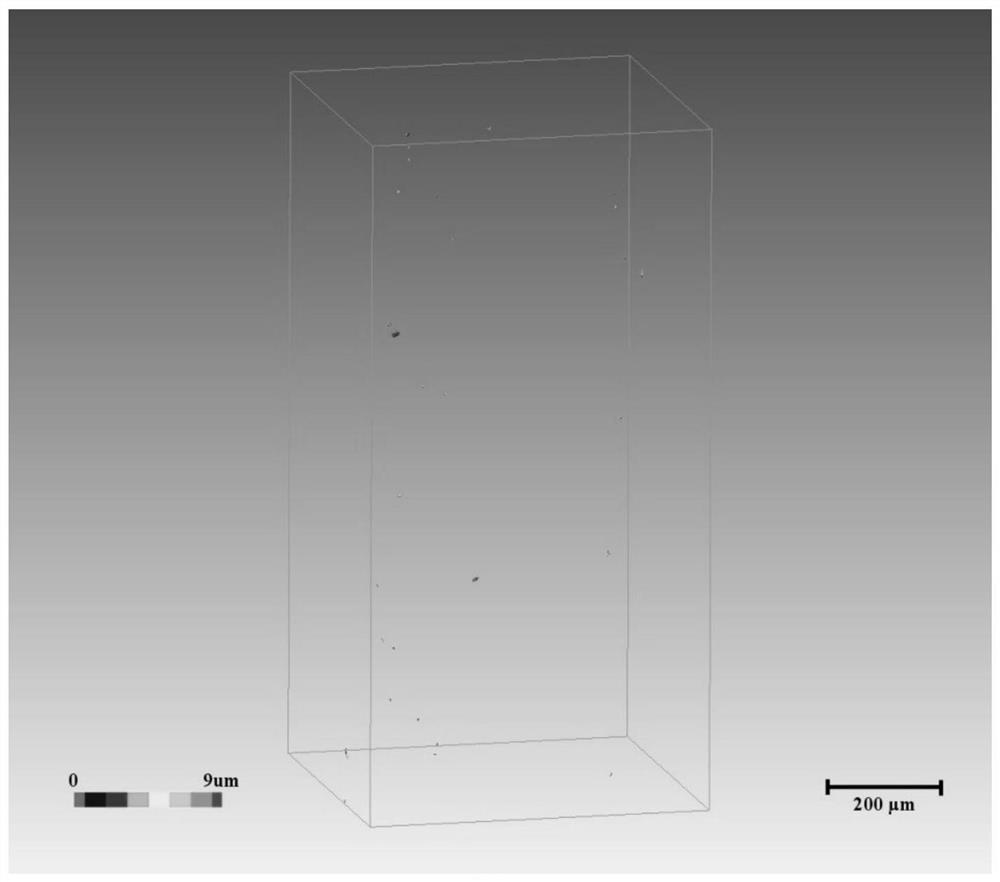

[0072] The step of preparing a consumable ingot: performing vacuum consumable remelting treatment on the ingot after vacuum induction melting to prepare a consumable ingot. Specifically, a Φ350mm ingot was used as the electrode blank, and vacuum consumable remelting treatment was carried out; wherein, during the vacuum consumable remelting treatment process, the melting power was adjusted and the mold was forced to cool, and the gap was increased under the condition of water cooling of the mold. Air-cooled, so that the depth / width of the molten pool (the depth refers to the depth of the center of the molten pool; the width refers to the diameter of the consumable ingot) is controlled to be 0.55.

[0073] Wherein, the equivalent diameter size of the largest carbide in the consumable ingot prepared in this step is less than 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com