Plastic waste recovery device and plastic waste recovery method

A plastic waste and recycling device technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of defective quality of recycled plastics, and achieve the effects of improving utilization rate, improving drying effect, and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

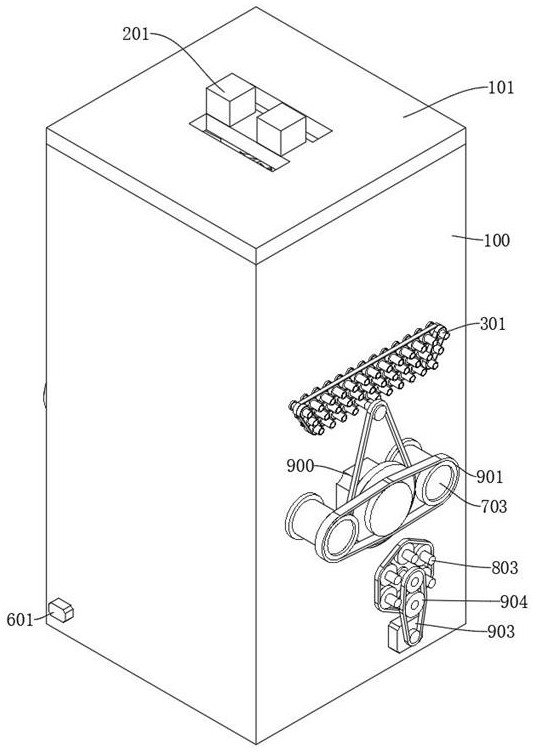

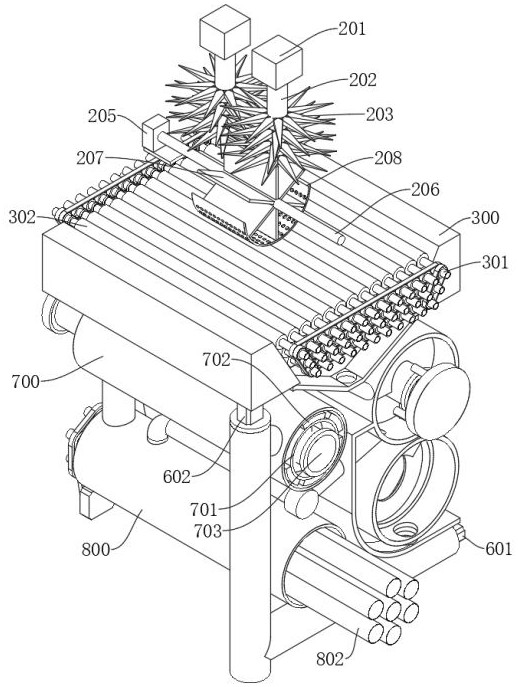

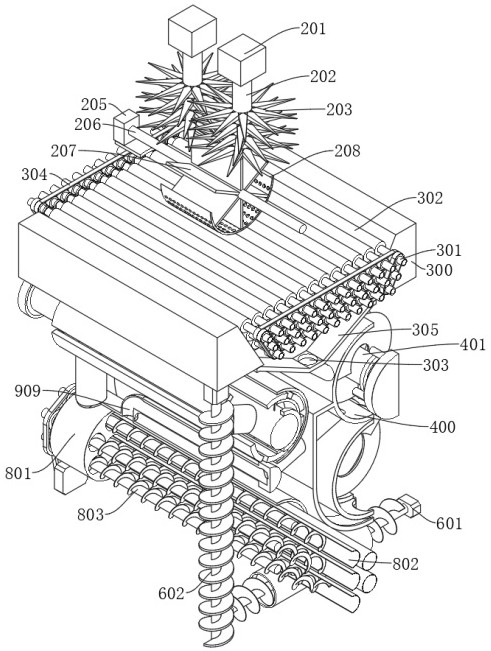

[0040] Example: refer to Figure 1-Figure 9 , a plastic waste recycling device, comprising an installation box 100 and a box cover 101 fixedly connected to the top of the installation box 100, the installation box 100 is fixedly connected with a first installation cylinder 400, and the first installation cylinder 400 is rotatably connected with a first hinge Dragon 401, an installation cavity 402 is opened in the shaft of the first auger 401, a fixed shaft 403 is rotatably connected in the installation cavity 402, a fixed plate 406 is fixedly connected to the outer wall of the installation box 100, and the fixed shaft 403 is fixedly connected with the fixed plate 406, A stirring rod 405 is rotatably connected to the shaft of the first auger 401, and the stirring rod 405 is connected with the fixed shaft 403 through a bevel gear set 404; it also includes a hot-melt assembly fixedly installed in the installation box 100 for melting the plastic waste; The third installation cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com