Carrier overturning and clamping mechanism

A clamping mechanism and clamping mechanism technology, applied in the field of automation, can solve the problems of reduced space utilization, low control accuracy, and large manipulator volume, and achieve the effects of reduced labor intensity, good stability, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following combined with the attachment and the specific embodiments further explain the present invention, so that the technical personnel in the art can better understand the present invention and implement it, but the implementation examples are not limited to the invention.

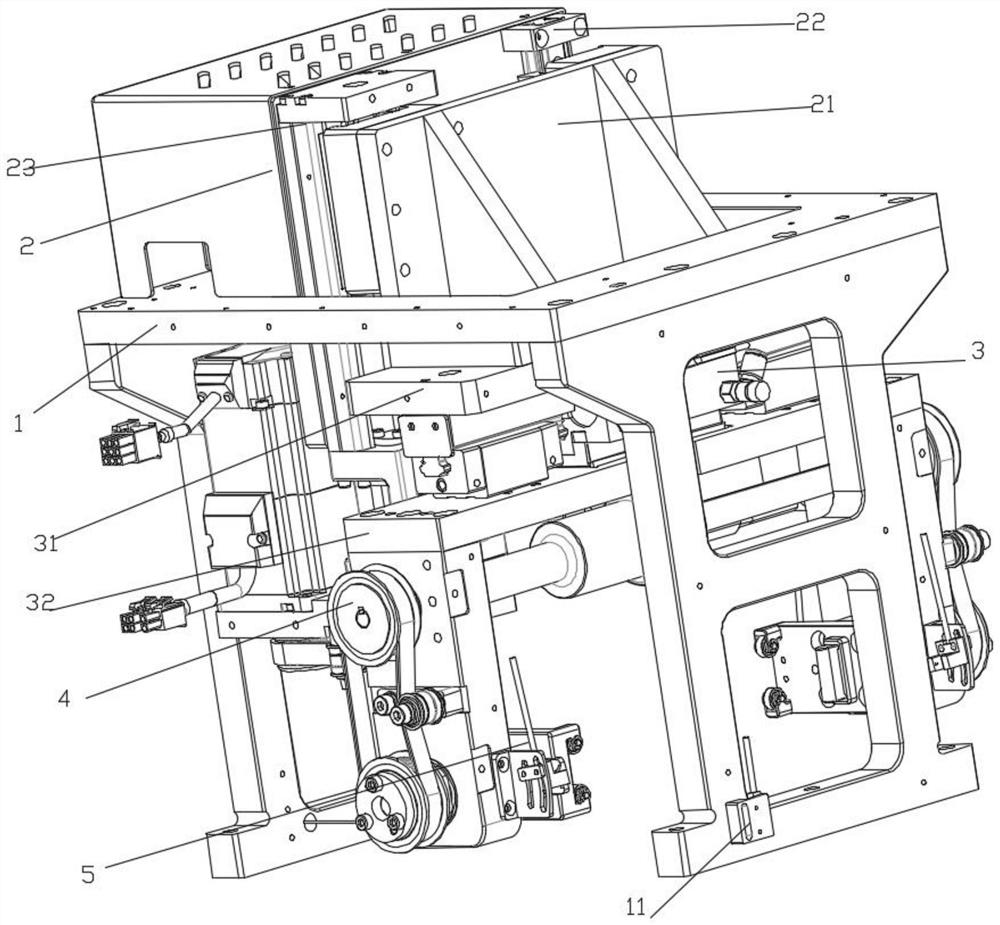

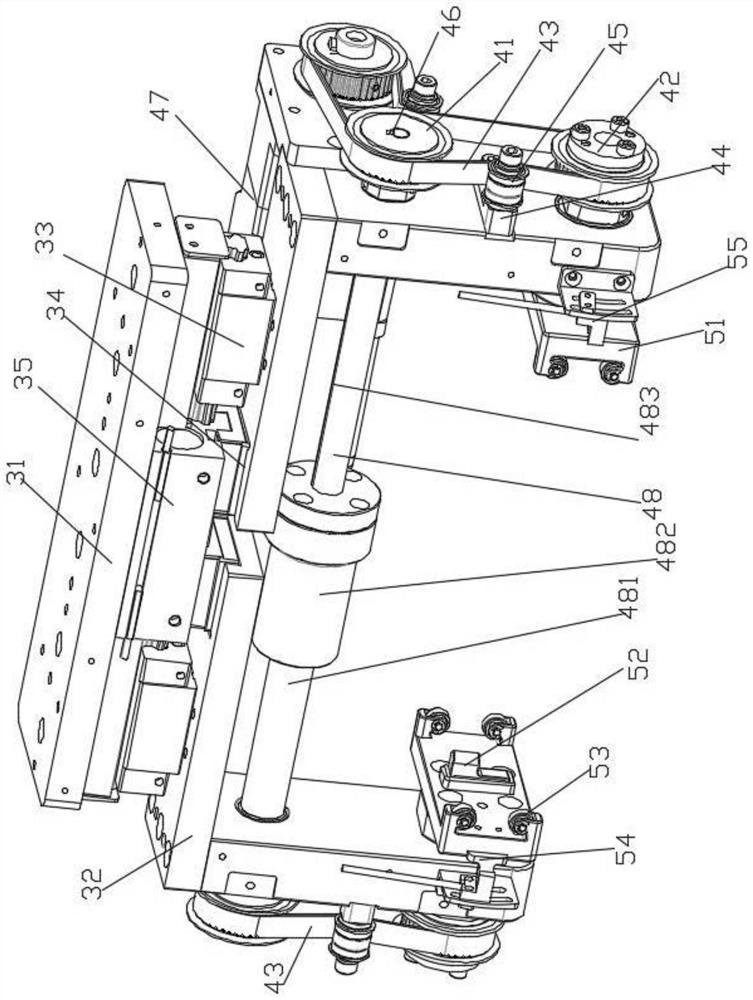

[0022] Reference Figure 1-2 It shows, a vehicle flipping and clamping mechanism, including Rangers 1, has a lifting mechanism on the rack 1, which is connected to the clamping mechanism 3 driver. 3 Do the lifting movement, and the holding mechanism 3 is set up with two feeding points 5, which is driven by the rotary mechanism.

[0023] The holding mechanism 3 includes two clip holders 32, two clip holders 32 to connect to the drive component drive connection, which drives the two clip holders 32 for relative movement. On the shelf 32, the product is held by the product to hold the product with 5 pairs of products through the drive component; Rotating components 4 connect to the 5 -wheel drive of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com