Asynchronous hanging basket with triangular truss type hoisting equipment and use method of asynchronous hanging basket

A lifting device and truss-type technology, applied in the field of asynchronous hanging baskets, can solve problems such as unsatisfactory construction of corrugated steel web bridges, increased weight of hanging baskets, and reduced safety, so as to save manpower and investment in mechanical equipment, shorten Effects of construction period, avoidance of idleness and conflict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

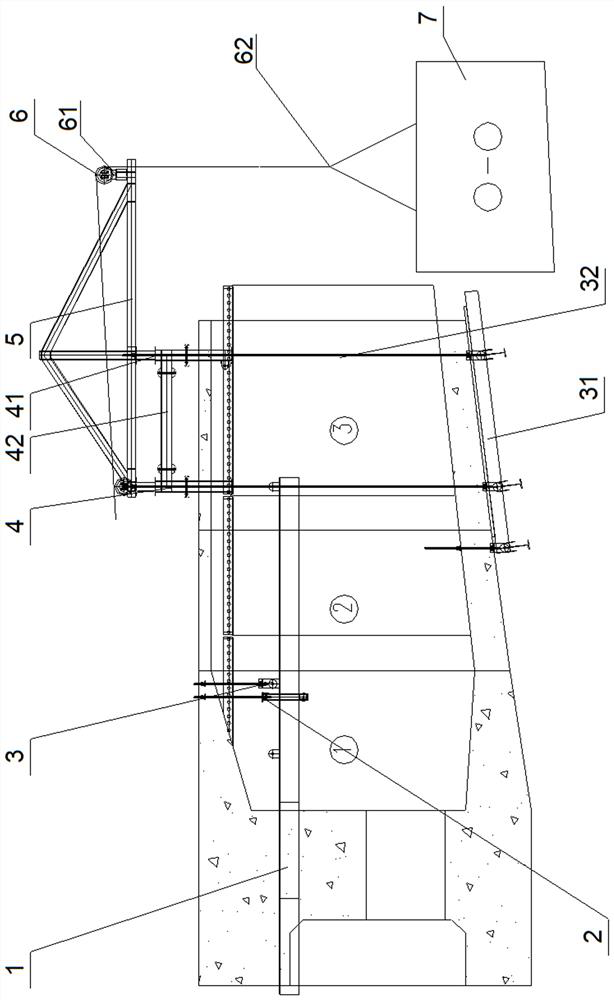

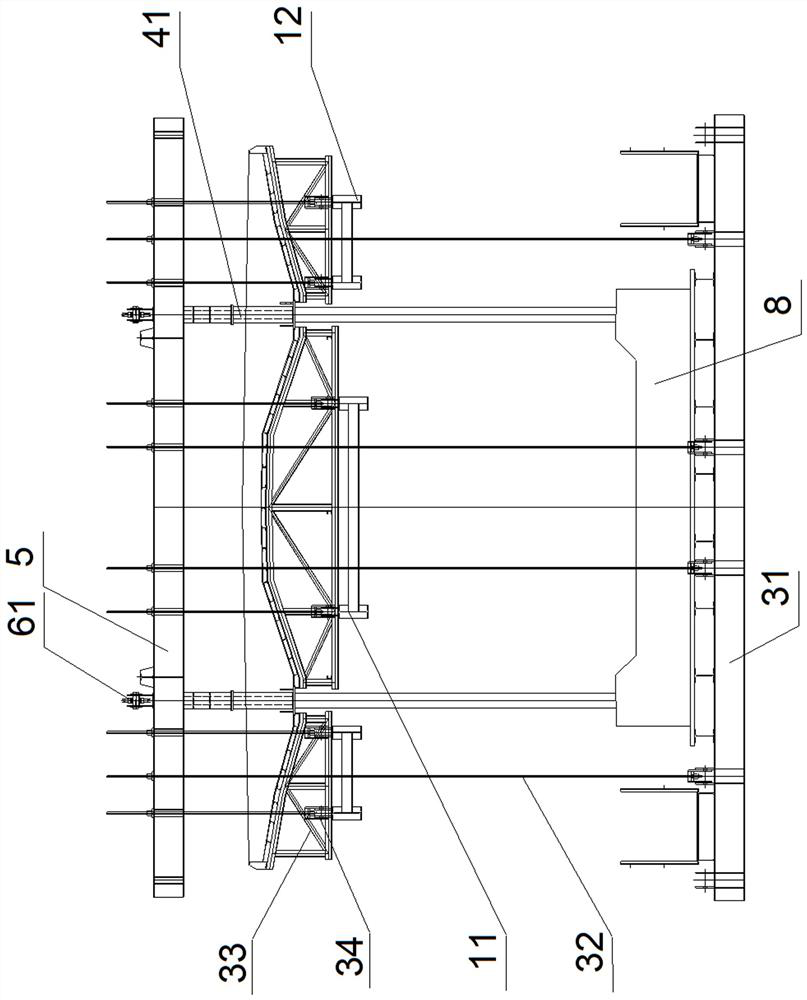

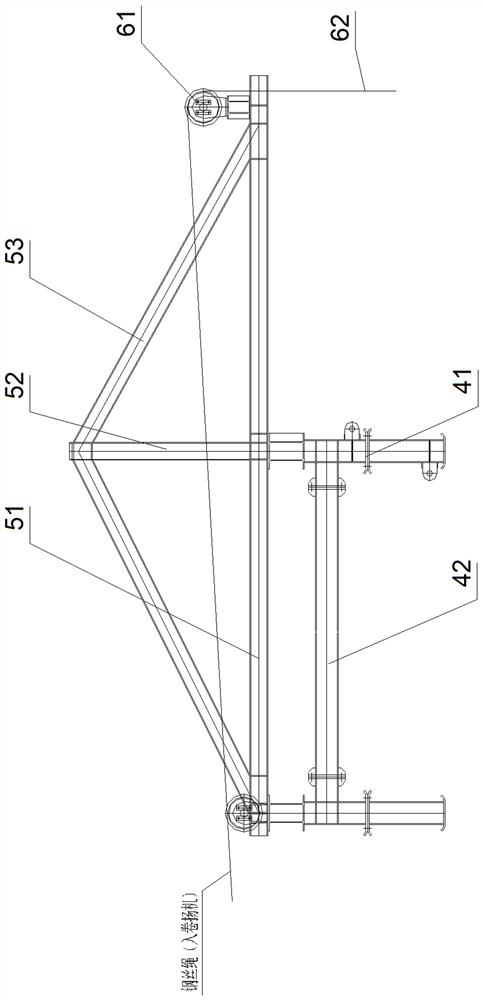

[0042] like Figure 1 to Figure 4 As shown, an asynchronous hanging basket with its own triangular truss type hoisting equipment includes: a sliding beam mechanism 1, a suspension mechanism 3, a hanging basket mechanism 5, a walking mechanism 2, a supporting mechanism 4 and a lifting mechanism 6. The present invention has a relatively Strong stability, can solve the problem of insufficient lifting capacity and insufficient lifting range of tower cranes in the existing construction, and also solve the problem that the use of large-scale tower cranes or large-scale hoisting machinery contradicts economic benefits and construction efficiency; the invention can effectively improve construction efficiency , to avoid labor and conflicts caused by the use of machinery, thereby saving the investment of manpower and machinery and equipment, reducing construction costs and shortening the construction period.

[0043] The sliding beam mechanism 1 is fixedly connected to the upper surface...

Embodiment 2

[0049] like Figure 1 to Figure 4 As shown, an asynchronous hanging basket with its own triangular truss type hoisting equipment includes: a sliding beam mechanism 1, a suspension mechanism 3, a hanging basket mechanism 5, a walking mechanism 2, a supporting mechanism 4 and a lifting mechanism 6. The present invention has a relatively Strong stability, can solve the problem of insufficient lifting capacity and insufficient lifting range of tower cranes in the existing construction, and also solve the problem that the use of large-scale tower cranes or large-scale hoisting machinery contradicts economic benefits and construction efficiency; the invention can effectively improve construction efficiency , to avoid labor and conflict caused by the use of machinery, thereby saving the investment of manpower and machinery and equipment, reducing construction costs and shortening the construction period

[0050] The sliding beam mechanism 1 is fixedly connected with the upper surface...

Embodiment 3

[0057] A method for using an asynchronous hanging basket with a self-contained triangular truss type hoisting device, comprising the following steps:

[0058] Step 1. Use tower cranes or other lifting equipment to complete the construction of the corrugated steel webs of block 0 and block 1;

[0059] Step 2. Use a tower crane or other lifting equipment to install the corrugated steel web of the No. 2 segment, use the tower crane to install the hanging basket mechanism, and pour the concrete of the No. 2 segment bottom plate;

[0060] Step 3. Install the lifting mechanism on the hanging basket mechanism, and install the hoist of the lifting mechanism at the corresponding position of the bridge deck;

[0061] Step 4. Use transport vehicles and cranes to transport the steel web to be installed below the hanging basket mechanism of the segment to be lifted. The corrugated steel web is lifted by the lifting mechanism for positioning and installation, and the top plate of the No. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com